Multitasking and multilingual, Quantum software offers easy access to all the functionalities of the instrument (control of poly and mono operation, management of the patented PolyscanTM pulsed operation, etc.). Quantum can be used for data treatment on other computers in emulation mode while the instrument is making measurements.

Powerful and flexible data handling with the unique functionalities of Time Plus (to increase analysis time during measurement), UFS (Ultra Fast Sputtering) to enhance the erosion of polymers and measurement with multiple acquisition frequencies. Real time display of acquisition, ultra fast treatment options (including multiple smoothing), automatic determination of interfaces, calculation of trends and export of results as images, ascii or xls files for flexible reports generation.

Creation and use of analytical tasks to apply similar treatments on multiple results for overlay and comparison of multiple results.

Record of all raw data allowing flexible reprocessing, ability to display the entire depth profile measurement from a bulk result, to use layered samples in any program or to apply bulk programs for surface measurements and depth profile programs for bulk.

IQ

Intelligent Quantification models including the Sputtering Rate mode that follows the ISO standard and the new Layer Mode for advanced materials. Measurement of concentrations (in At%, M% vs depth, coating weights, layer thicknesses). 2D/3D associated crater profiles.

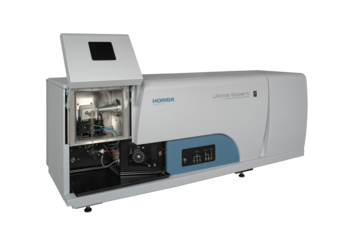

Image

When the monochromator is used in a scanning mode (with a measurement at every picometer) the entire emission spectrum of a material can be recorded with the highest optical resolution and without saturation as the HDD is used. This is called the “Image”.

Two minutes are needed for acquisition of the full fingerprint of bulk samples and thick layers (or even thinner layers using pulsed operation). Materials can be compared through their “Images”, and a database of wavelengths identifies the elements present.