Applications

HORIBA Automotive provides innovative applications and insights, advanced automotive validation and verification technologies and equipment, and ongoing guidance and consultation to client partners across the globe. With 75 years of unmatched comprehensive scientific measurement and data management proficiencies. Our ever-expanding engineering expertise and ongoing innovations provide customers with complete vehicle development solutions that solve industry challenges.

We deliver all of this from a prevailing position of lasting leadership, established integrity, recognized reliability, and continual collaboration.

Join HORIBA at hall 13, booth C34 at the HANNOVER MESSE 2024, the world’s leading trade show for industry and technology.

This webinar will cover the topics of quality assurance & end of line testing in fuel cell and electrolyzer series production.

April 30, 2024 at…

Don't miss Steve Whelan, Program director of HORIBA MIRA, speaking about "Intelligent labs – the future of development" on June 5, 10 AM, Hall 8.

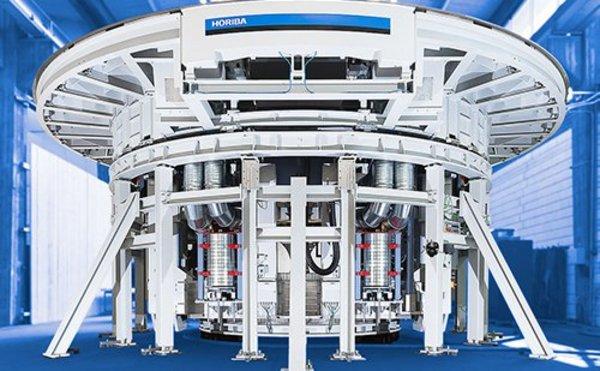

HORIBA Europe's David Schroeck, Global Product Manager Wind Tunnel Technologies, explains what and why a wind tunnel balance is essential...

This year’s theme is ‘Analytical and Measurement Technologies for a Clean Water Environment and Sustainable Society.’

HORIBA, Ltd. established “Our Future” (Vision, Mission, Values) for the HORIBA Group on January 26, the anniversary of its foundation.

The HORIBA…

Do you have any questions or requests? Use this form to contact our specialists.