| Product name | Laser scanning type surface oil detector | |||

|---|---|---|---|---|

| Model number | LO-300 | |||

| Subject of detection | Oil on water surface or liquid on floor | |||

| Detection method | Surface scanning laser/reflected light sensor | |||

| Detection distance | 0.3 m to 4 m (Piezometric surface Max.6 m) | |||

| Laser emitter | Semiconductor laser, wavelength (λ) 650 nm, within 1 mW output (Class 2) | |||

| Modulation laser freq | About 50 kHz | |||

| Scanning Mechanical | Oscillation mirror | |||

| Leak detection | Leak detection alert | When the state to exceed a set level of “Oil WARNING” or “OIL ALARM” passes longer than “CONT.TIME SET.”, it judges alert. | ||

| System Error | Malfunction | Engages when Temp., laser emission, laser scanning, motor rotation or power fails. | ||

| Abnormal light sensing | Engages when Upper light reception level, Lower light reception level, floating debris produces no reflection or abnormally strong reflection. | |||

| Contact output | Number of outputs | 2 | ||

| Output type | No-voltage contact output | |||

| Contact type | Relay contact; SPDT(1c) | |||

| Output capacity | 250 V AC 4 A,30 V DC 4 A | |||

| Output 1 | AL (Oil Alarm) | When “OIL ALARM” is detected, it operates. | ||

| Output 2 | ER (System Error) | When “System Error” is detected, it operates. | ||

| Transmission output | Number of outputs | 1 | ||

| Output type | 4 mA to 20 mA DC (Isolator) | |||

| Load resistance | Max. 550 Ω | |||

| Setting and Indication | (Indication) | Status of water surface | NORMAL RUN | |

| OIL WARNING | ||||

| OIL ALARM | ||||

| HIGH LEVEL | ||||

| LOW LEVEL | ||||

| SYSTEM ERROR | ||||

| Light reception level | 4 mA to 20 mA is transformed converted into Level bar of 17 Step. | |||

| Surface Oil area | 0% to 100% is transformed converted into Level bar of 10 Step. | |||

| LOG | Max. 100 points Alarm history | |||

| (Setting) | OIL LEVEL | Adjustment: 4 mA to 20 mA (1 mA carving) Indication: red △ marker under LEVEL bar | ||

| AREA LEVEL | Adjustment: 0% to 90% (10% carving) Indication: △ marker under AREA bar Oil warning: Yellow △ Oil alarm: Red △ | |||

| CONT.TIME | Adjustment: 0 seconds to 999 seconds (1 second carving) | |||

| RELAY OUT (AL) | Adjustment: MODE: Select of Oil warning or Oil Alarm TIME : 0 seconds to 99 seconds, ∞(infinity) | |||

| LEVEL ERR. | Adjustment: “ON” or “OFF” | |||

| MULTI-TRANS | Adjustment: “ON” or “OFF” | |||

| OVER LEVEL | Adjustment: 4 mA to 24 mA | |||

| DATE | Adjustment: Year/Month/Day/Hour/Minute | |||

| CONTRAST | Adjustment: CONTRAST LEVEL of LCD | |||

| COLOR | Adjustment: COLOR of LCD | |||

| FACTORY | Adjustment: at the time of shipment from the factory | |||

| Laser replacement Contact output time setting | Adjustment: 0:00 to 23:59 (unit 1 minute) | |||

| Power supply | Power range | 100 V AC ±10% 50/60 Hz | ||

| Power consumption | 100 W less than | |||

| Other | With time-lag fuse (125 V 2 A) | |||

| Operating temperature range | −10℃ to +50℃ (without freeze) | |||

| Operating humidity range | Relative humidity: 5% to 95% (without condensation) | |||

| Compatible standards | CE marking | EMC Directive: EN61326-1 | ||

| Low-voltage Directive: EN61010-1, EN60825-1 | ||||

| Structure | Installation | Outdoor installation type | ||

| Protection code | IP66 corresponding | |||

| Material | Detection part | AL (Chromate processing after urethane painting) | ||

| Setting and Indication part | AL (Alumite processing after urethane painting) | |||

| Paint color | U35-85B (Edition U of JPMA) | |||

| External dimensions | φ185 mm × H547 mm | |||

| Mass | Main body: Approx. 11 kg; Cables: Approx. 1.4 kg | |||

| Installation condition | Installation inclination: less ±3° It avoids direct sunlight and it sets it up. Frozen provisions of the surface of the water of detection are necessary. The rain avoiding provisions are necessary. | |||

| Attached cable | Power cable | 1 cable (Length:5 m NA6UCL AWG16 × 3 cores (outer diameter φ10.4)) | ||

| Signal cable | 1 cable (Length:5 m NA3VCSB AWG21 (0.5 sq) × 8 cores with shield (outer diameter φ8.5)) | |||

LO-300

Laser scanning oil film detector

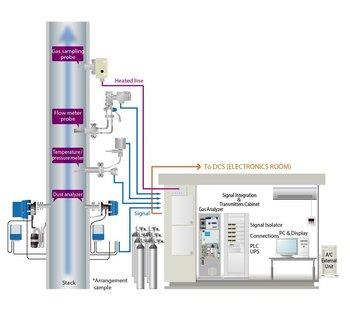

In the event of an oil spill, laser and video monitoring will be employed.

The LO-300 is a laser scanning oil film detector that accurately detects floating oil films by scanning the water surface with a semiconductor laser beam. Highly effective in detecting floating oil films on water surfaces or floor surfaces. Additionally, the surveillance camera unit (optional) allows the recording of video footage immediately before and after the occurrence of an alarm.

![]()

![]()

![]()

![]()

Easy-to-read color LCD

With the use of a large 3.5-inch color LCD (with touch panel), visibility and operability are improved. The light-receiving level is displayed graphically in color, making it easy to see the monitoring status at a glance. Moreover, it an automatic power-off feature is incorporated for use during long periods of inactivity, ensuring energy efficiency and prolonging the lifespan of the device.

Versatility of functions

Alarm triggering can be set as either WARNING or ALARM. Additionally, accumulated operating hours of the laser module are managed, notifying the user when maintenance is recommended.

Detection height of 0.3 to 4.0 m

Improved wave resistance enables monitoring at a height of 4 m even on the surface of flowing water (our conventional unit + 1 m). Monitoring capability can increase to 6 meters on still water surfaces. Additionally, continuous line scanning is also followed in order to monitor oil film on a wide laser scanning plane.

Possible to set the size of the oil film to trigger an alarm

Alarm determination can be based on the percentage (%) of the water surface covered by the oil film. Capable of preventing false alarms triggered by causes other than oil spills, such as floating debris, iron bacteria, insects, or fish.

*This feature is effective within a detection distance of 2 meters in calm water surfaces.

Significantly extended light source life to 4 years

Through significant design improvements, the maintenance cycle has been extended to 4 years (twice as long as our previous device).

Based on cumulative operating time, the monitor displays a replacement message for the semiconductor laser. Furthermore, it can be easily installed without the need for optical axis adjustment, following the bell-shaped structure.

Surveillance camera (optional)

Water surface condition are recorded before and after an alarm is triggered. Allowing for easy determination between oil film detection and false detection, the inclusion of date and time in the captured images facilitates verification. Furthermore, remote monitoring can be enabled through the installation of LAN cables.