| Name | Tunable Laser Gas Analyzer |

| Model | TX-100 |

| Measurement target | HCl and H2O in process gas |

| Measurement component | HCl, or HCl and H2O simultaneous measurement |

| Measurement principle | Non Dispersive Infrared (NDIR) |

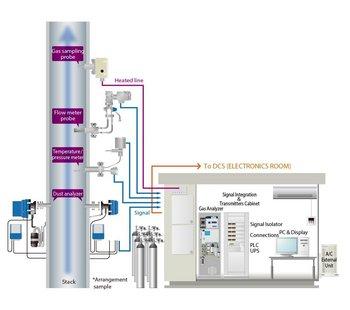

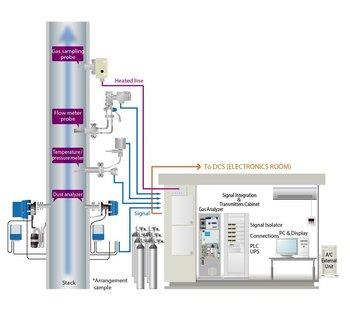

| Measurement type | Probe type |

| Laser class | CLASS1(IEC60825-1: 2014) |

| Protection degree | IP65 |

| Wetted materials | SUS316L、SUS304、BK7、FKM、PTFE、aluminum alloy |

| Tube connections | Rc1/8 (Tube of 8 mm O.D./6 mm I.D.) |

| External dimentions | Analyzer: Max: 358 (W) x 517 (D) x 453 (H) mm |

| Weight | Analyzer: 19 kg |

| Flange specifications | JIS10K-100AFF、JIS5K-125AFF、ANSI 150 Lb 4BRF |

| Power supply voltage | DC24V±10% |

| Power consumption | 90 W |

| Display | LCD (128 × 64 dots), LED (3 units: Status display) |

| Display contents | Gas concentration, transmission, process gas temperature, process gas pressure, system status, alarm information, system information (product serial no., output signal, IP address, optical path length, analyzer unit internal temperature) |

| Communication | ModbusTM/TCP |

| Analog input/output | Input: |

Output: | |

| Digital input/output | Input: |

| Output: Two channels (Warning/Calibration/Warm-up/Maintenance state/Fault) Relay contact output (isolated output) Max. 24 V, 1 A at each terminal |

*You can select either fixed value or real time HCl correction using H2O concentration.

-Modbus is a trademark of Schneider Electric Inc.

-Consult HORIBA if special probe length is required.

Performance

| Measurement component | HCl, H2O |

| Measurement range (250℃、101.3kPa) | HCl: 0-50,100,200,300,400,500 ppm*1 H2O: 0-50 vol% |

| Measured optical path length | 2m |

| Repeatability | HCl: +/- 1.0% F.S. H2O: +/- 2.0% F.S. |

| Linearity | HCl: +/- 1.0% F.S. H2O: +/- 2.0% F.S. |

| Zero drift | +/- 2.0% F.S. / 6 months |

| Span drift | +/- 2.0% F.S. / 6 months |

| Data update cycle | Approx. 2sec |

| Recommended Calibration cycle | 6 months |

| Calibration method | HCl: Manual calibration using gas cell H2O: Factory calibration*2 |

| Interference | +/- 2.0% F.S. |

| Warm-up time | 3hours |

*1: Select a measurement range.

*2: You can adjust the H2O indicated value to the manual analysis value. Consult HORIBA for more details.

Usage Conditions

| Ambient temperature | -20 ~ 55°C (no direct sun rays, radiant heat and heat conduction from flange) |

| Ambient humidity | Relative humidity: 90% or less (no condensation) |

| Dust | Ambient criterion or less |

| Air purge | Instrument air (must not contain oil or mist; no dew formation) |

| Air purge flow rate | 60 L/min or more (depend on the process gas conditions) |

| Vibration | At 1 to 200 Hz, 1.96 m/s2 or less (excluding resonant frequency) |

| Process gas conditions | Temperature: 150 to 250°C Pressure: 101.3 ± 10 kPa Flow speed: 25m/s Dust: 0.1mg/Nm3 or less |

* This value is supplied pressure to TX-100 main unit. In case air passes through the purge unit, the pressure value at the purge unit is 0.2 to 0.9 MPa.