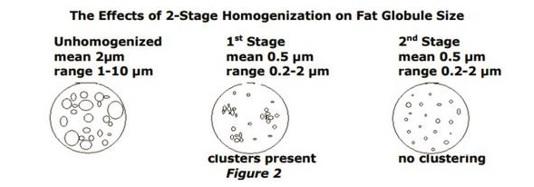

Milk is a very complex food containing over 100,000 different molecular species. Cow’s milk is composed of 87% water, 3.5% protein, 3.7% fat, 4.9% lactose, and 0.7% salts. The main components of interest are protein and fat globules. The proteins, referred to as casein particles combine together with calcium and phosphate to form aggregates with a well-defined structure. Their typical size is in the range of 100 nm. They are white, tasteless and odorless and are used to make food, paint, and adhesives. In contrast, the fat globules in raw unhomogenized milk are between 1-10 µm, while in homogenized milk the size range is 0.2-2 µm.

Milk is an oil-in-water emulsion, with the fat globules dispersed in a continuous phase of skim milk. If raw milk were left to stand the fat globules would form a cream layer and rise to the surface.

Homogenization is a mechanical process used to reduce the size of the fat globules in the milk. The net result of this process is a decreased creaming rate according to Stokes’ Law, reduced clustering during creaming, and better density matching with the continuous phase.

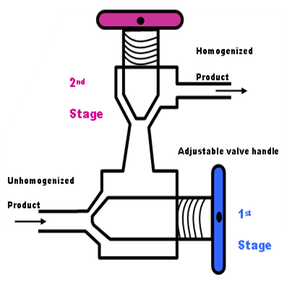

The homogenization process reduces the globule size by passing milk under high pressure through a tiny orifice. To understand the mechanism, consider a conventional homogenizing valve (Figure 1) processing an emulsion such as milk at a flow rate of 20,000 l/hr. As it first enters the valve, liquid velocity is about 4 to 6 m/s. It then moves into the gap between the valve and the valve seat and its velocity increases to 120 meters/sec in about 0.2 milliseconds. The liquid then moves across the face of the valve seat and exits in about 50 microseconds. The homogenization phenomenon is completed before the fluid leaves the area between the valve and the seat.

Figure 1

While most of the fat globule reduction takes place in the first stage, there is a tendency for clumping or clustering of the reduced fat globules. The second stage valve shown in Figure 1 permits the separation of those clusters into individual fat globules, as seen in Figure 2 below. The second stage is similar to the first stage, as seen in the diagram above. The two-stage homogenizer permits precise control of the homogenization process. Different valve setting give different size emulsions, which in turn affect the final products’ stability, taste, and shelf life.

The LA-350 has proven to be a popular analyzer for monitoring this process because of its low cost and ease of operation. The analyzer can be placed at each milk plant to provide real-time feedback on the homogenization process. This allows for optimization of the final product, cost savings by eliminating overprocessing of the material and out-of spec material, and evaluation of the homogenizer itself for wear or breakage.

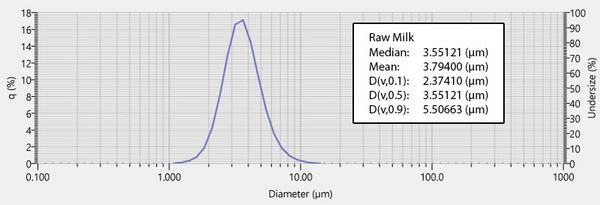

The distribution below is the result of measurement of whole raw, (unhomogenized milk) with the LA-350 particle size analyzer. The distribution shows the large fat globules prior to homogenization. The ratio and size of fat globules to casein is such that the caseins are not seen in whole milk.

Particle Size of Raw Milk

In the 2% milk, where a large portion of the fat has been removed, the main peak stays centered around one micron while a slight shoulder appears on the small side. This represents the caseins which now show up in the distribution, due to the removal of the fat globules.

The main goal of homogenization is to break up the large fat globules and create a stable emulsion that has an increased shelf life, a better taste, and improved mouth feel. The LA-350 is an excellent tool to monitor this process. It is able to show the large end of the distribution shift from 10 µm to about 2 µm without a problem. Also, in the low fat milk it is able to see the size distribution of the proteins.

For those customers who have a larger capital budget, the LA-960V2 would provide even more data at the smaller size ranges where the proteins are seen in addition to monitoring the reduction in fat globule size in the large size range.

Laser Scattering Particle Size Distribution Analyzer

Laser Scattering Particle Size Distribution Analyzer

Do you have any questions or requests? Use this form to contact our specialists.