The importance of particle size for power plants is found in their ability to meet environmental regulations while controlling capital expenditures and operating costs. The size of materials such as limestone, lime, and trona impacts the efficiency of desulfurization processes. By-products such as gypsum and fly ash may be sold to various applications depending on their size as well. This application page will show how investing in particle size analysis helps control operating costs and improve margins for power plants.

Many technologies exist to remove SOx, NOx, and other components from the flue gas produced by power plants. Some of those technologies utilize materials to react with the flue gas to cleanse it of pollutants. The particle size distribution of those materials directly impacts the efficiency of the emission control method. A short description of the particle size-related technologies follows.

As the name implies, flue gas desulfurization methods aim to remove SO2 from the process stream. The "wet" version of the method typically involves limestone and water to force oxidation. Gypsum is produced as a by-product and may be re-used or sold after dewatering. The dry, or semi-dry, version of the method often features a lime slurry which is atomized and injected into the flue gas. SO2 removal efficiencies for the two versions are similar for low-sulfur fuels.

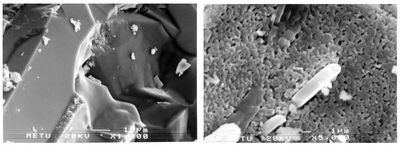

For flue gases producing too much SO3, dry sorbent injection may be used to meet emission targets. Common sorbents include trona (sodium sesquicarbonate) and baking soda (sodium bicarbonate). Both materials will calcine above a certain temperature and remove SO3 and SO2 (somewhat less efficiently), creating a sodium sulfate salt as a by-product. The calcination process critically determines the dry sorbent efficiency as the evolution of water and carbon dioxide creates a more porous structure, thus increasing the number of reaction sites, thus improving the SOx removal efficiency.

SEM images of trona before (left) and after (right) calcination

View Webinar: Particle Characterization of Trona

This talk will be useful for anyone in the power or mining industries and will reference laser diffraction and flowing gas surface area technologies.

The LA-960 Laser Particle Size Analyzer quickly and easily measures dry powders such as trona or wet materials such as a lime slurry. Any sample with particle size between 10 nanometers and 5 millimeters may be measured in less than 60 seconds with the LA-960. Dry powders are measured using the PowderJet accessory.

Adding sample to the LA-960 PowderJet.

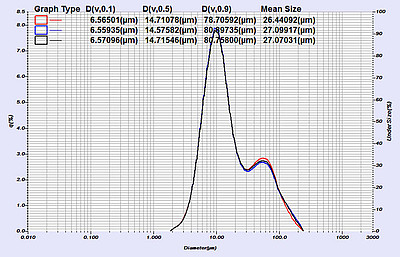

Particle size overlay of multiple fly ash measurements using the LA-960 PowderJet.

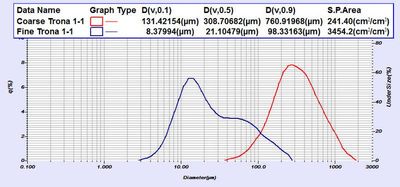

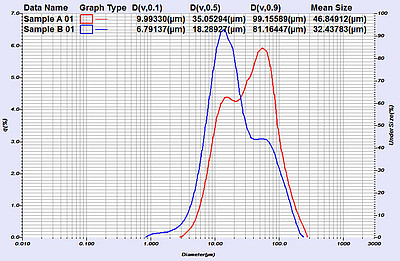

Comparison of fine and coarse samples of trona as measured by the LA-960 PowderJet.

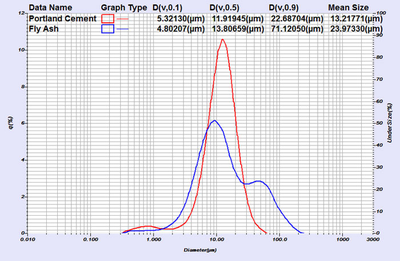

Overlay of fly ash and Portland cement as measured by the HORIBA LA-960.

Particle size distribution of gypsum produced in flue gas desulfurization.

The LA-960 Laser Particle Size Analyzer easily measures materials either consumed or produced by power plants. Capable of measuring powders, slurries, and suspensions between ten nanometers and five millimeters with only a single mouse click, the LA-series has the performance and ease of use required by users in this environment. The LA-350 represents a portable, liquid-only sizing option for users with slightly different needs.

Laser Scattering Particle Size Distribution Analyzer

Laser Scattering Particle Size Distribution Analyzer

Do you have any questions or requests? Use this form to contact our specialists.