Titanium dioxide is present in many aspects of everyday life, its inclusion in commonplace goods often surprising. TiO2's utility in sunscreen -- affecting SPF and opacity -- is better known than its presence as a whitener in skim milk. The particle size of titanium dioxide directly impacts its performance in numerous applications, necessitating the measurement and control of this important property.

Most of the numerous useful properties of TiO2 are directly impacted by its particle size distribution. Size affects its final performance in hue & hiding, how it behaves in various formulations via flocculation tendency & viscosity, and its properties which are exploited for niche applications.

A partial list of properties affected by particle size includes:

Titanium dioxide is a key component of paints and primers.

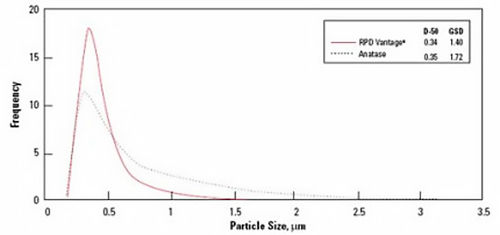

The importance of monitoring and controlling particle size is not theoretical; the world’s largest TiO2 manufacturers specify their products by particle size results including the D50 median and geometric standard deviation. Up and down the supply chain, particle size is monitored; most often by laser diffraction technology.

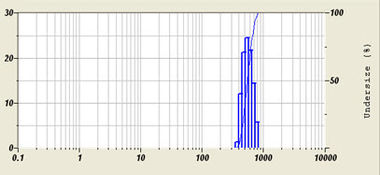

Example particle size result from TiO2 manufacturer

Most uses of titanium dioxide present a tougher dispersion challenge than other common applications. If you wish to measure a wet dispersion, it's recommended to explore the aid of surfactants, admixtures, and ultrasonic energy. If the measurement will be dry, then configure the particle size analyzer for maximum dispersive energy, e.g. small nozzles, high air pressure, feedback control.

DuPont has published a procedure to measure their Ti-Pure product which includes the following:

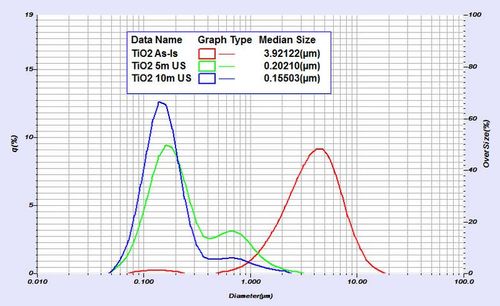

The importance of sample preparation to the measured particle size of TiO2 is apparent in the graph below.

Comparison of titanium dioxide size measurements after 0, 5, and 10 minutes of ultrasonic dispersion

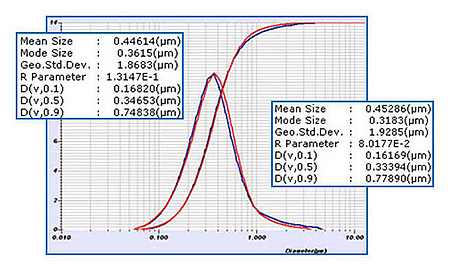

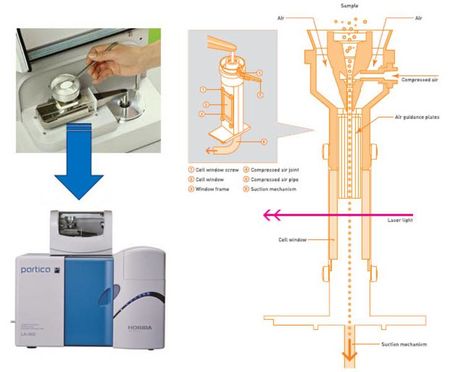

The LA-960V2 PowderJet accessory provides extremely powerful dry dispersion, enabling the accurate and reproducible measurement of titanium dioxide powders. The graph below shows the PowderJet's ability to reproducibly distinguish a 12 nanometer difference two different TiO2 powders.

LA-960V2 PowderJet distinguishes a 12 nanometer difference in the median sizes of two titanium dioxide powders.

The PowderJet achieves this remarkable resolution because it has been designed for maximum dispersion. It accelerates compressed air to subsonic speeds using a venturi nozzle. For more information, visit the PowderJet page.

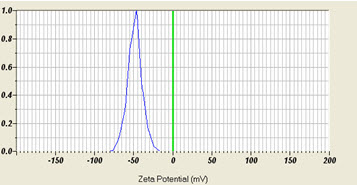

Certain TiO2 applications require stability analysis via zeta potential measurement. The SZ-100V2 Nanoparticle Analyzer can measure both the size and zeta potential for nanoparticle dispersions.

The particle size of titanium dioxide plays a crucial role in nearly all of its applications. Particle size analysis is a highly valued measurement all the way from upstream processing of titanium ore chunks to nanoparticle dispersions. HORIBA's array of measurement technologies and decades of application expertise ensure a solution to even the most demanding titanium dioxide applications.

Laser Scattering Particle Size Distribution Analyzer

Laser Scattering Particle Size Distribution Analyzer

Nanoparticle Analyzer

Do you have any questions or requests? Use this form to contact our specialists.