- Spectral ranges: from 190 to 10,000 nm

- Large range of groove densities: from 100 to 2000 gr/mm

- Diffraction efficiency optimized for UV, or Vis, or NIR

- Radius of curvature : from 100 to 1232 mm

- Dimensions : from 25 x 25 mm

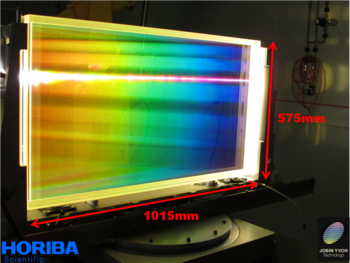

For customers in need of larger dimensions, HJY can record a custom-made holographic grating master specifically for replication.

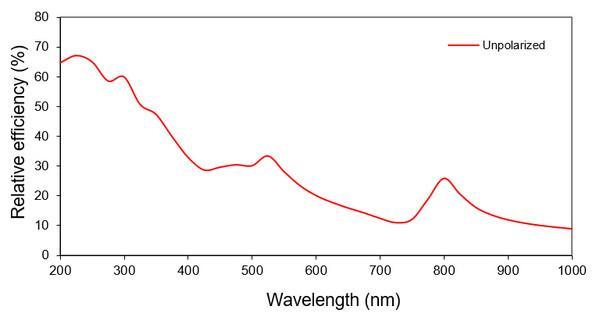

Fig. 3: Typical efficiency curve* for 532 00, 1200 l/mm, 190-1050 nm

*This efficiency curve is absolute theoretical efficiency, calculated using rigorous electromagnetic theory, taking into account the true groove profiles of manufactured gratings measured with an atomic force microscope (AFM).