FQ Series

Fuel Flow Measurement Systems

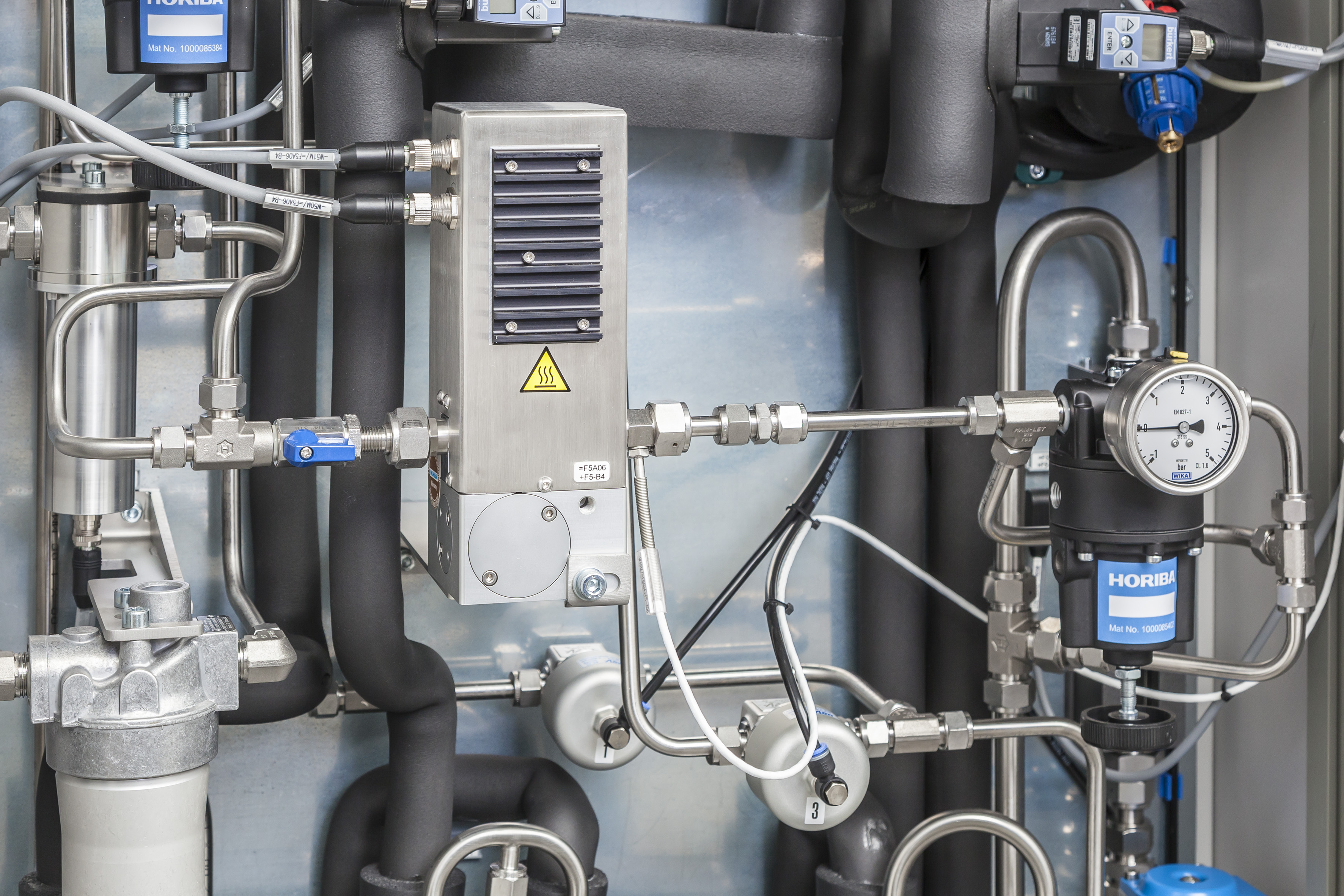

Measuring a vehicle’s fuel flow requires a precise system which can run stationary and transient tests. It must also be able to offer high reproducibility and run cycle measurements under real operational conditions, including WLTP. Our FQ Series of fuel flow measurement systems offers a highly precise method of measuring various fuel types, and covers the full range from small engines (incl. single-cylinder research engines) up to heavy-duty engines with up to 5000 kW.

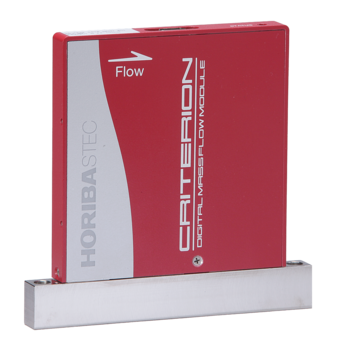

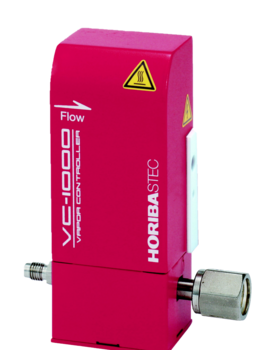

With the choice of two different measurement principles – the positive displacement principle and the Coriolis measurement principle – the systems are suited for a wide range of applications. These applications include durability, mapping, and performance testing as well as climatic and emissions tests.