Products used in ceramic and abrasive applications are invariably produced from powders. Particle size distribution has profound effects on processing and function of these products. These materials include most oxides and minerals from aluminum oxide to zirconium oxide. Depending on the application, particle size can effect densification, transport and mechanical properties. The range of particle sizes is broad, from less than 100 nm to greater than 100 µm. Laser diffraction, dynamic light scattering and acoustic spectroscopy have all been successfully utilized to characterize ceramic materials.

Particle size analysis plays a crucial role in the manufacture of electronic materials for dielectric applications. These materials include single-phase powders such as barium titanate as well as formulations that contain many different oxide phases. In all cases, the particle size distribution has a great impact on their processing and performance.

Solid oxide fuel cells (SOFC’s) offer the potential to greatly reduce man’s dependence on coal and oil for the production of electricity. They are clean, quiet and efficient. At the heart of these devices lies a complex combination of polycrystalline ceramic materials, each having to meet a particular set of structural and electrochemical requirements. Engineers control the performance of each component through manipulation of chemical and physical properties of the starting powders. Particle size is of critical importance to the powder properties and to the performance of the cells. Laser diffraction particle size analysis has proven to be an excellent way to monitor and control particle size for these materials during powder synthesis and component fabrication.

The most accurate results obtained from laser diffraction requires some knowledge of the refractive index of the sample. This can be challenging when the sample contains a mixture of powders, as is often the case with ceramic materials. This application note describes several approaches for choosing the refractive index for powder mixtures including a case study for a ZrO2-Y2O3-Al3O3 mixture.

Alumina (aluminum oxide, Al2O3) has widespread use in the ceramics industry for refractory materials, abrasives, and porcelain. Many different sizes and chemically modified grades are available. Particle size affects the manufacturing and mechanical properties of these components, including packing density and mechanical strength of the final part. These materials are usually dispersed in water for measurement, with surfactant added to prevent agglomeration.

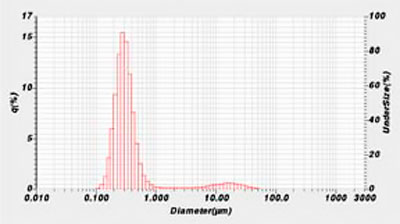

Synthetic iron oxide powders are used primarily for their pigmentary and magnetic properties (although not all types of iron oxide are magnetic). The category of iron oxide powders includes all types of synthetic iron oxides (hematite, magnetite, maghemite, etc.) and ferrite powders also, as the latter materials have as their main constituent ferric oxide (Fe2O3). Iron oxide powders are the most widely used of all colored inorganic pigments, used in concrete products, paints, plastics, and other media. Due to their chemical and magnetic properties, iron oxide powders also find significant commercial usage in electromagnetic components, catalysts, toners, magnetic recording media, and other applications.

Laser Scattering Particle Size Distribution Analyzer

Do you have any questions or requests? Use this form to contact our specialists.