Lithium-ion (Li-ion) batteries power modern technologies from smartphones to electric vehicles. But they also carry a critical risk: thermal runaway. This self-sustaining chemical reaction generates heat, releases hazardous gases, and in extreme cases, can cause fires or explosions.

Understanding and measuring battery thermal runaway emissions is essential for improving safety, advancing battery design, and reducing environmental and health risks.

During a thermal runaway event, Li-ion battery components rapidly break down, releasing heat and a complex mix of gases and particles. These emissions include carbon dioxide, hydrogen, ammonia, and fine particulates, each with unique safety and environmental implications.

By studying the gases generated at every stage of thermal runaway, researchers can:

Ready to advance your battery safety testing? Contact our team today to discuss your testing needs.

HORIBA leverages decades of expertise in emissions measurement technology to deliver a comprehensive view of battery thermal runaway behavior. Our systems integrate:

Combined with proprietary system designs for initiating and evaluating thermal runaway, HORIBA provides a complete solution for safety, research, and regulatory compliance.

Our suite of test equipment provides high-resolution analysis of thermal runaway emissions, supporting EV manufacturers, researchers, and regulatory bodies:

FTX-ONE RS

FTIR Exhaust Gas Analyzer: 5Hz sampling rate and simultaneously measure the concentrations of multiple components including NH3, CH4, and CO2.

FTIR Exhaust Gas Analyzer: 5Hz sampling rate and simultaneously measure the concentrations of multiple components including NH3, CH4, and CO2.

HyEVO

Hydrogen Gas Analyzer: High-accuracy, high-resolution hydrogen gas analyzer designed to support the development of the hydrogen supply chain.

Hydrogen Gas Analyzer: High-accuracy, high-resolution hydrogen gas analyzer designed to support the development of the hydrogen supply chain.

SPCS-ONE

Solid Particle Counting System: Can complete engine/vehicle certification testing for PN defined in the latest regulations, which requires complied dilution systems.

Solid Particle Counting System: Can complete engine/vehicle certification testing for PN defined in the latest regulations, which requires complied dilution systems.

PX-375

Continuous Particulate Monitor with X-ray Fluorescence: Combines X-Ray Fluorescence & Beta-ray attenuation for accurate measurement of inorganic compounds.

Continuous Particulate Monitor with X-ray Fluorescence: Combines X-Ray Fluorescence & Beta-ray attenuation for accurate measurement of inorganic compounds.

Beyond real-time measurement, HORIBA offers advanced particle analyzers for post-test evaluation of thermal runaway emissions. These tools enable detailed morphology, chemical composition, and elemental mapping of battery particles:

Partica LA-960V2

Laser Scattering Particle Size Distribution Analyzer: Measures particle size distribution of emissions using laser diffraction and image analysis.

Laser Scattering Particle Size Distribution Analyzer: Measures particle size distribution of emissions using laser diffraction and image analysis.

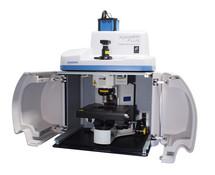

XploRA™ PLUS

Particle-Correlated Confocal Raman Microscope: Performs particle morphology analysis and automated chemical identification of each particle.

Particle-Correlated Confocal Raman Microscope: Performs particle morphology analysis and automated chemical identification of each particle.

XGT-9000

X-Ray Analytical Microscope (Micro-XRF): Automated analysis of elemental composition of each particle. Data can be correlated with Raman microscopy data for complete particle morphology-chemical identification analysis.

X-Ray Analytical Microscope (Micro-XRF): Automated analysis of elemental composition of each particle. Data can be correlated with Raman microscopy data for complete particle morphology-chemical identification analysis.

nanoGPS navYX™

Particle-Correlated SEM Imaging & Analysis Solution: Automated analysis of each particle with multiple characterization methods, including SEM, AFM, FTIR, Raman, and more.

Particle-Correlated SEM Imaging & Analysis Solution: Automated analysis of each particle with multiple characterization methods, including SEM, AFM, FTIR, Raman, and more.

Measuring battery thermal runaway emissions is key to safer, cleaner energy storage. HORIBA delivers the insights to move electrification forward with confidence.

如您有任何疑問,请在此留下詳細需求或問題,我們將竭誠您服務。