Key Features:

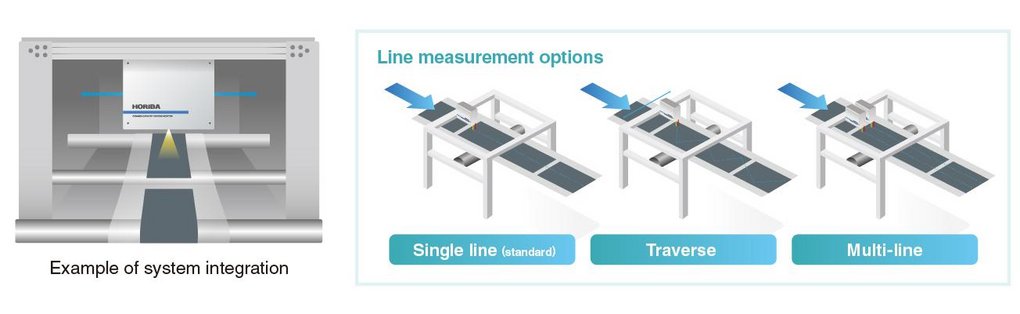

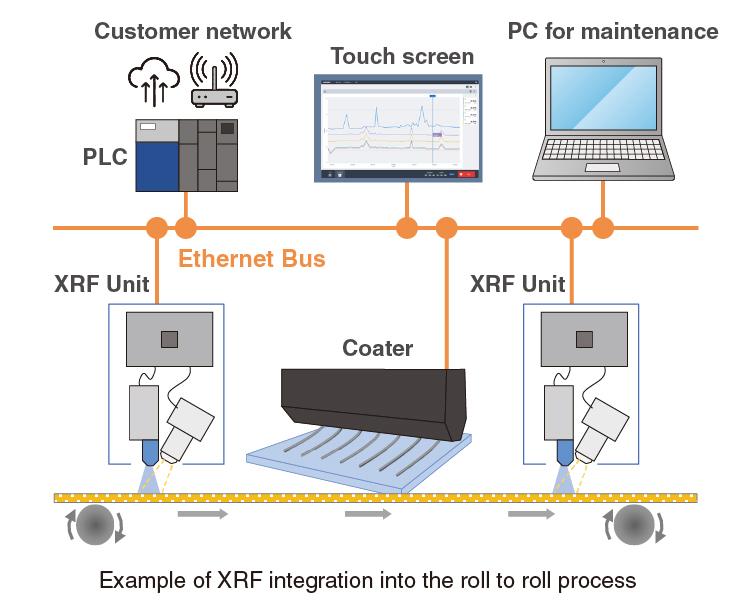

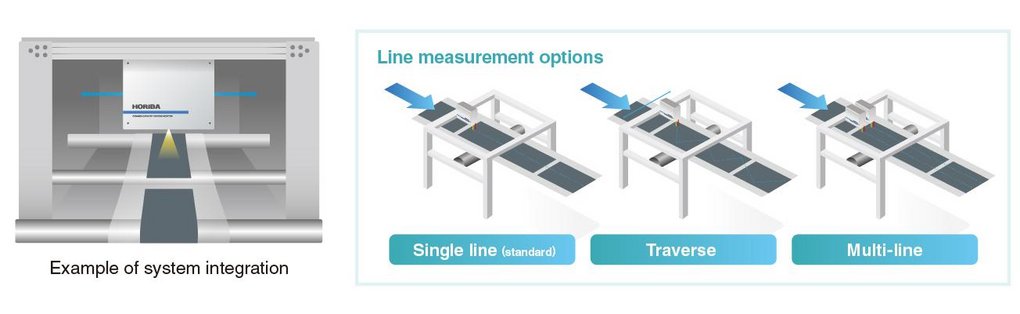

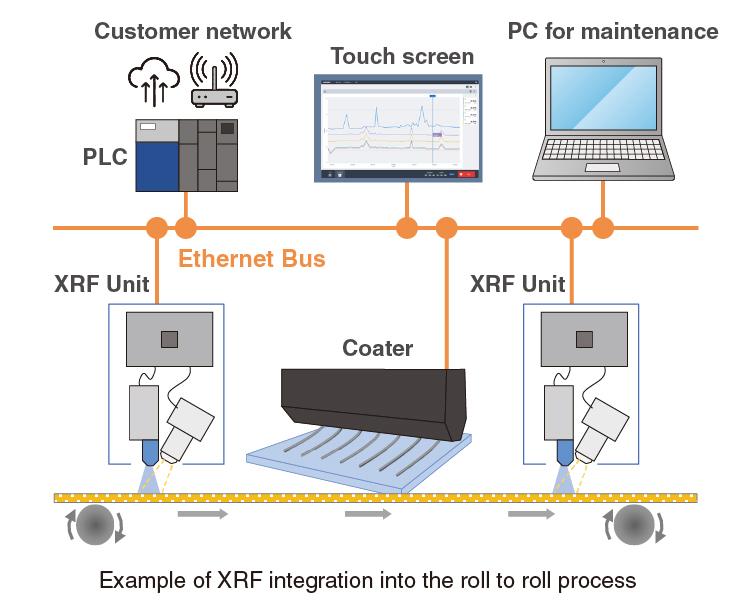

- Seamless Integration: Designed for easy integration into roll-to-roll processes, complete with X-ray protection measures.

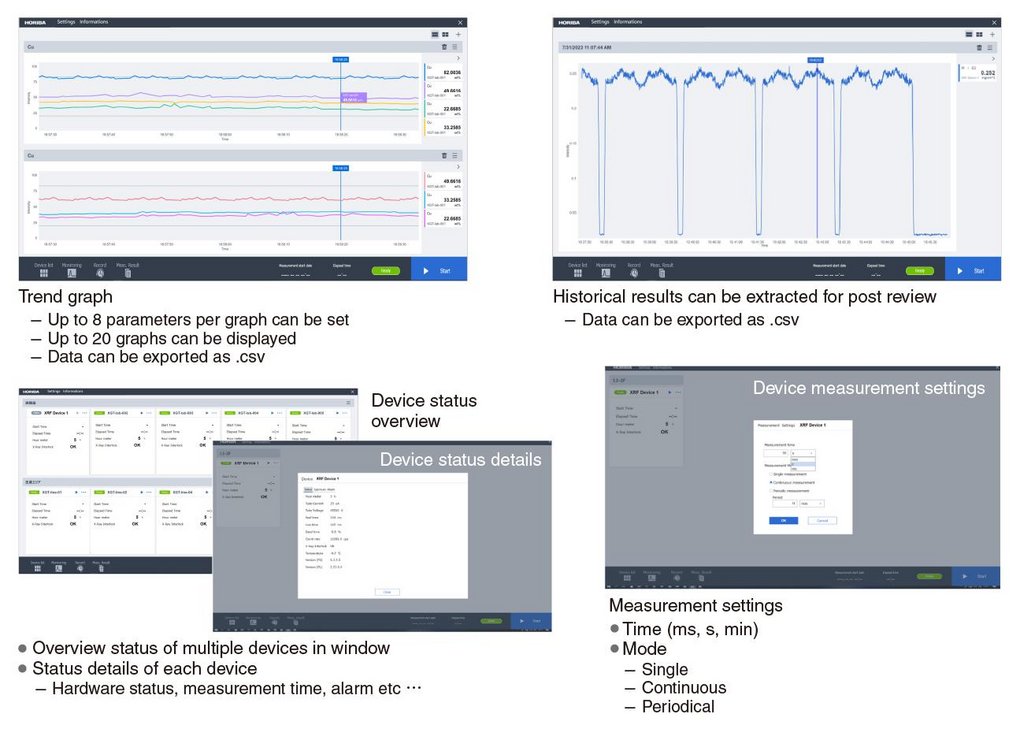

- Modular Software: Highly connective and modular software facilitates in-line process monitoring.

- Compatibility: Compatible with standard communication protocols for streamlined integration into existing systems.

1. Optimizing Catalyst Use in Fuel Cell and Electrolyzer Manufacturing

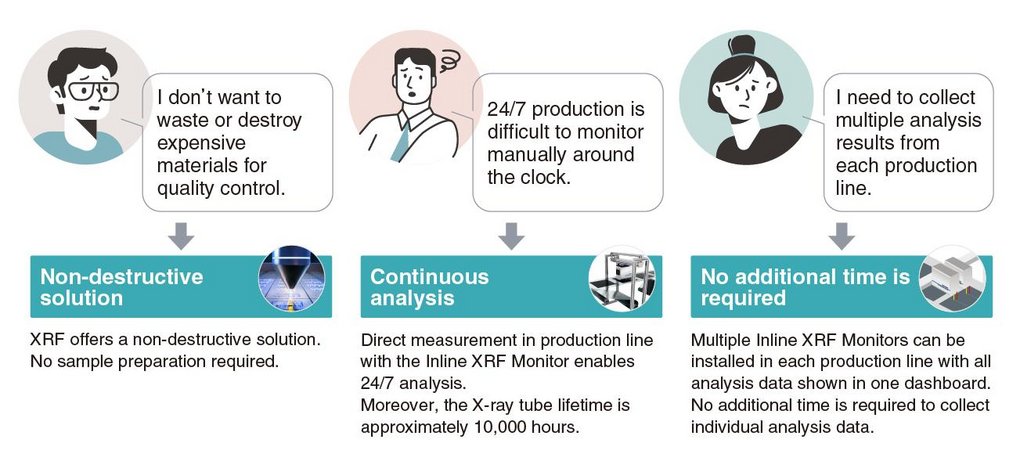

To achieve carbon neutrality, green hydrogen is a crucial energy source. Both electrolyzers and fuel cells use catalyst-coated, semi-permeable membranes to separate reactants (MEA: Membrane Electrolyte Assembly). These membranes (PEMFC*) have multiple layers, one of which contains platinum or other platinum group metals (PGMs) as catalysts. However, PGMs are precious materials and require strict quality control with non-destructive analysis methods. HORIBA introduces Inline X-ray fluorescence analysis (XRF) that achieves highly reliable and precise non-contact measurement and control functionality of the PGM content in this layer.

*Proton Exchange Membrane Fuel Cell

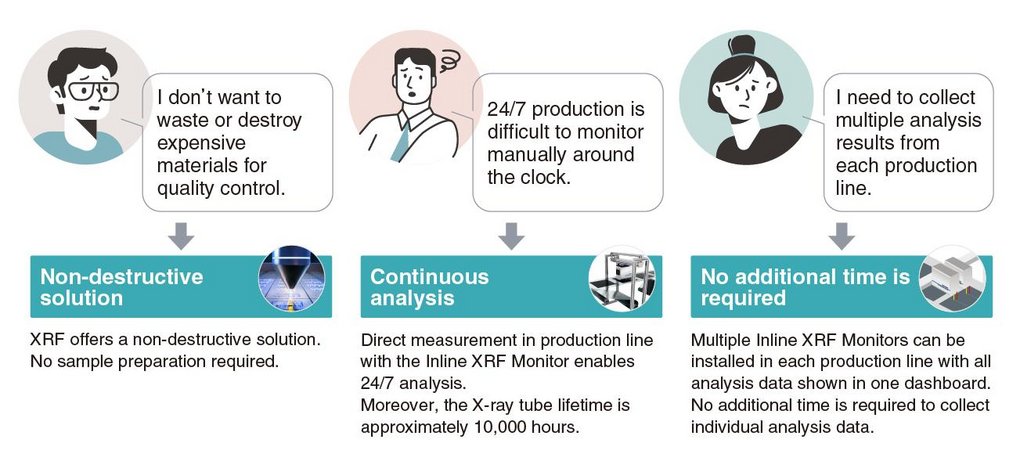

2. Why Choose Inline XRF for Catalyst Quality Control?

3. Advantages of HORIBA XV-100

Based on more than 50 years of experience in X-ray technology and manufacturing process analysis, we have designed the XV-100 for process analysis.

- Realtime energy correction allows stable operation

- Integrated distance correction for objects with large vertical fluctuations

- Durability of X-ray tube (10,000 hours*1)

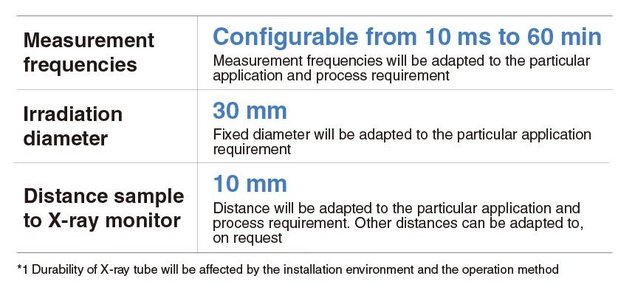

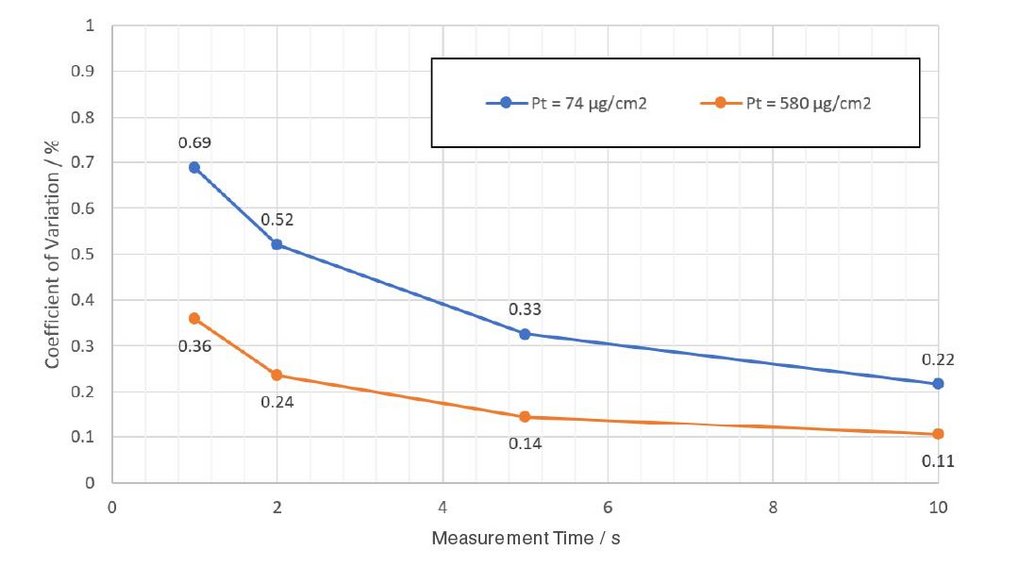

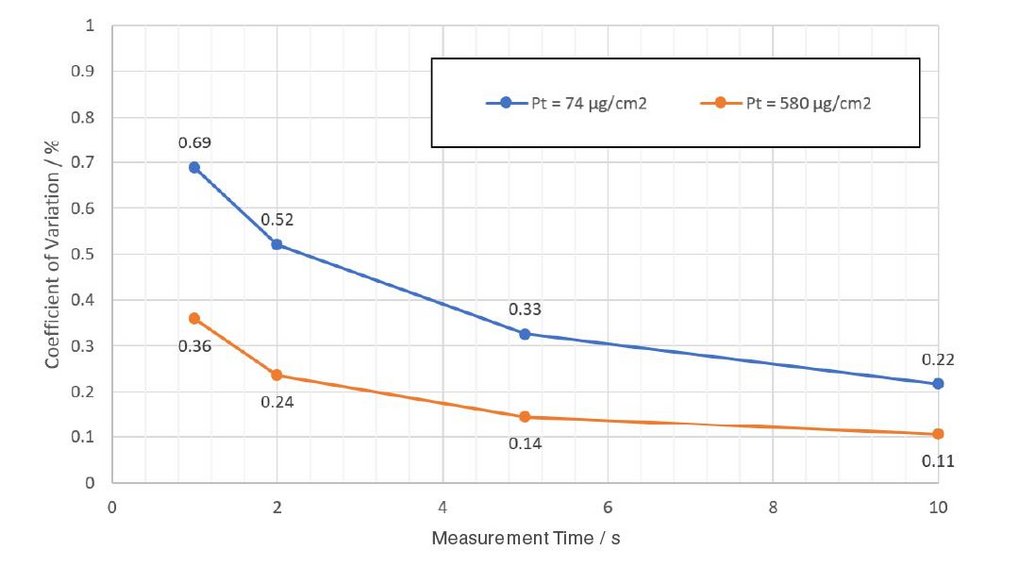

- Achieve high sensitivity at industry-leading measurement speeds

- Compact, lightweight design allows flexible installation in any location

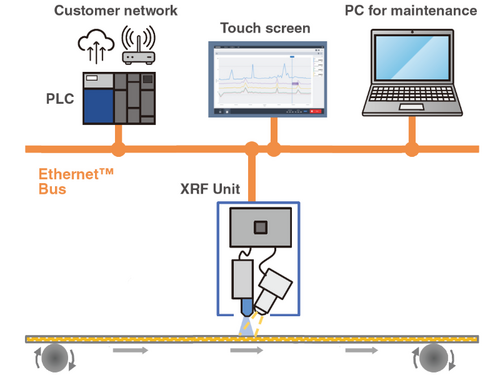

4. Seamless Integration with Your Production Systems

- Connectable to industrial network via PLC* or PC

- Multiple devices (XRF units, other companies’ devices such as coaters) can be synchronized and measured

- HORIBA’s original firmware and built in microprocessor designed for direct PLC connectivity (stable operation without conventional method of PC)

* Programmable Logic Computer

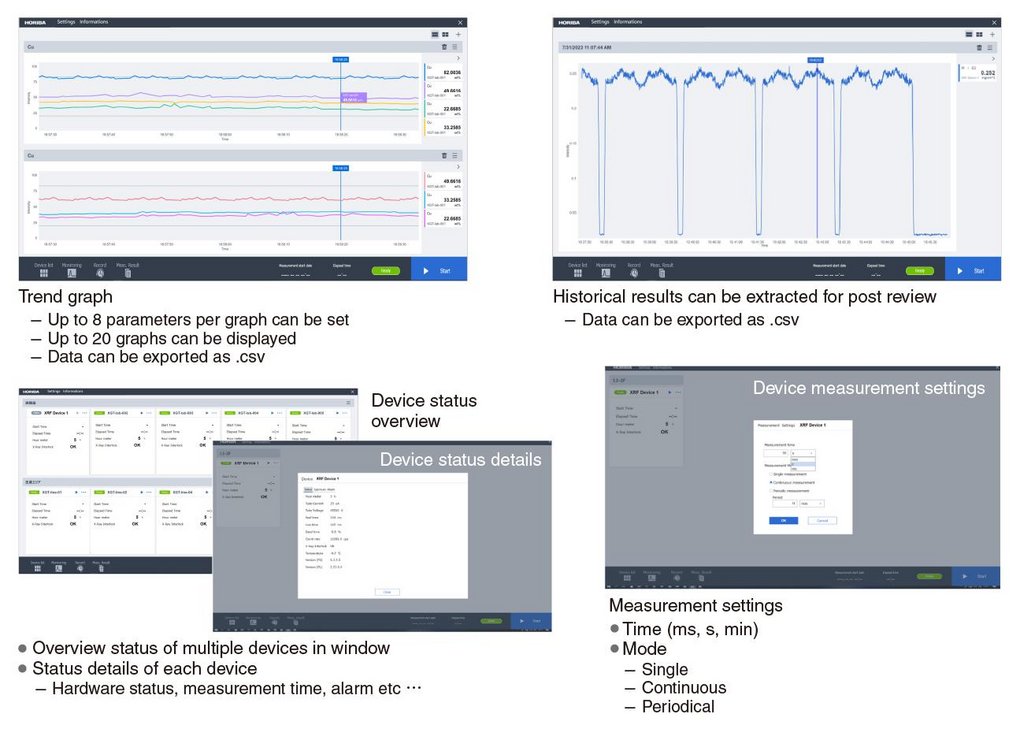

5. Intuitive Software Designed for Industrial Efficiency

Software GUI for standalone operation with XV-100

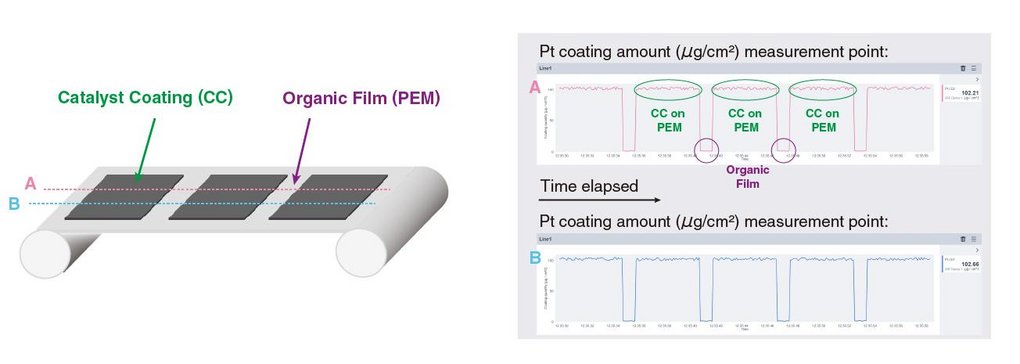

6. Set up: Roll to Roll Coating Inspection for Fuel Cell and Electrolyzer

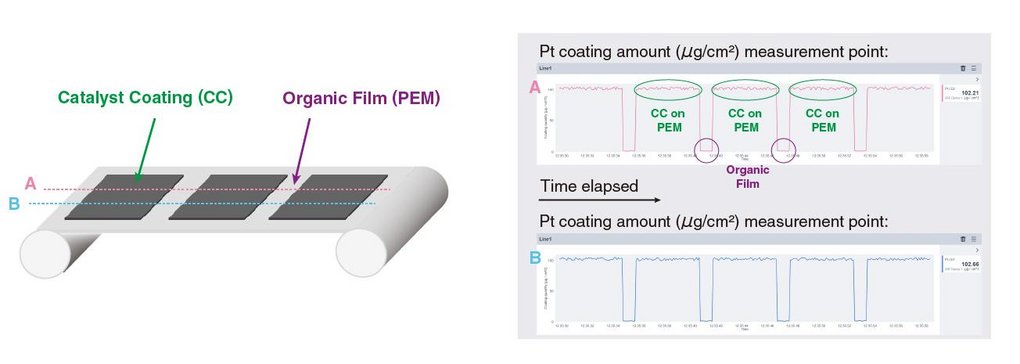

When the CCM* passes the measurement point of the XV-100, the amount of Pt corresponding to the catalyst thickness is displayed on the graph. When the organic film passes, it is not detected.

*Catalyst Coated Membrane

7. Additional Capabilities

XV-100 is a standalone monitor, but it can also meet additional requirements such as traverse units, X-ray shielding mechanisms, and data transmission.