Oxygen, with its highly reactive characteristics to form oxides, plays an important role in many fields such as steel industry, healthcare industry, food industry etc. Among them is also semiconductor industry with gate dielectric film formation / gate electrode formation, the application that particularly uses Ultra High Purity Oxygen (UHPO). The purity of UHPO is usually 99.9995% or higher and it is mainly produced at Air Separation Unit (ASU).

Atmospheric air taken into the ASU is compressed and goes through so called “cold box”. Over the process, major ambient air components such as oxygen, nitrogen, and argon are liquified and separated at different freezing points. For safety operations, and for further improvement of purity in the final product, additional purification unit is used in the end of the process.

In order to ensure the proper process operation, multiple analytical equipment is used. Particularly for methane (CH4) measurement, Flame Ionization Detection (FID) analyzer is commonly used, however, there are several challenges such as:

Cross-modulation dual-beam NDIR technique realizes remarkably improved zero drift & sensitivity for real time ppb level monitoring of CH4 in pure oxygen.

NDIR technique does not require hydrogen as utility gas, ensuring the safety of measurement.

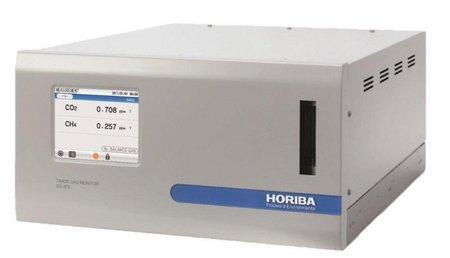

Figure1: Trace Gas Monitor GA-370

| Gases measured | CO, CO2, CH4 |

| Measurement ranges | 0-1/2/5/10 ppm |

| LDL | 10 ppb |

| Selectable range | 4 ranges |

| Repeatability | +/- 2% of full scale |

| Linearity | +/- 2% of full scale |

| Zero drift (week) | +/- 0.03 ppm |

| Span drift (week) | +/- 3% of full scale |

Figure2: Air Separation Unit

Molecules consisting of different atoms are known to absorb infrared light in a specific wavelength range. Non-dispersive infrared analyzer (later, NDIR) uses above physical property of molecules and measures infrared light absorption in the specific wavelength of CO, CO2, and/or CH4 in the sample gas and provides continues measurement of concentration value.

This method, known as the cross-modulation method, differs from conventional modulation with a chopper in the feature it uses a mechanism (modulation mechanism) in which a solenoid valve is switched at regular intervals to alternately introduce the sample gas and reference gas into the same gas cell.

This cross-modulation method has a very small drift and produces a stable output signal over the long term. Additionally, the diaphragm of the condenser microphone moves to the left and right (double the amount of signal when using a chopper), which improves noise immunity. Unlike the chopper, no adjustment is required when servicing the modulation mechanism.

Furthermore, to reduce interference effects caused by interference component gases with wavelength bands close to the specific wavelength absorbed by the measurement component, a compensation detector for interference components is incorporated to achieve highly accurate measurement of gas concentration. The combination of NDIR with a cross-modulation method and a compensation detector for the interference component enables highly accurate measurement at the ppb level.

Figure3: Cross-Modulation Dual-Beam Non-Dispersive Infrared Technique. Flow Schematic

Trace Gas Monitor

Do you have any questions or requests? Use this form to contact our specialists.