Chemical mechanical polishing (CMP) is a powerful fabrication technique that uses chemical oxidation and mechanical abrasion to remove material and achieve very high levels of planarity.

Chemical mechanical planarization has been widely applied to selectively remove materials for topography planarization and device structure formation in semiconductor manufacturing. The selective material removal is achieved by using chemical reaction and mechanical abrasion with slurries containing unique chemical formulations and large numbers of abrasive particles. During polishing, chemical reaction products and mechanical wear debris are generated. Slurry particles and polishing byproducts are pressed onto wafer surface. During wafer transferring from polisher to cleaner, contaminants are adhered onto wafer surface. Post-CMP cleaning is required to remove particles, organic residues, and metallic contaminants from wafers with different surface, chemical, and mechanical properties in various geometric features, without generating scratches, water marks, surface roughness, corrosion, and dielectric constant shift.

HORIBA can offer the following analysis for CMP process:

Chemical mechanical polishing (or planarization) is the most popular technique for removing the surface irregularities of silicon wafers. Typical CMP slurries consist of a nano-sized abrasive dispersed in acidic or basic solution. A chemical reaction softens the material during mechanical abrasion. The abrasive particles have a size distribution which directly affects critical metrics including rate of removal and wafer defects. Particle size analysis is therefore a key indicator of CMP slurry performance.

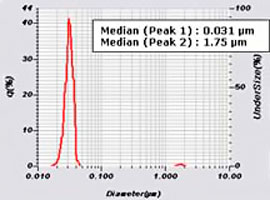

The typical size range of CMP abrasive particles is 50-250 nanometers and several particle sizing techniques are capable of measuring in this range with varying accuracy and precision. The typical oversize aggregate in CMP slurry is 1-10 microns and appears in the ppm range. The particle characterization challenge comes from the combination of accurately sizing the nano-scale particles while also identifying a relative few micron-scale aggregates.

Fine Particle Characterization in Chemical Mechanical Planarization (CMP) Slurries with Fluorescence Correlation Spectroscopy

with Prof. Edward E. Remsen | Bradley University, Mund-Lagowski Department of Chemistry & Biochemistry

and Tim Holt Applications Lab Manager | HORIBA Instruments, Semiconductor Segment

Fabrication of commercial integrated circuits depends critically on the physical and chemical properties of the abrasive slurry particles used to polish silicon wafer surfaces via chemical-mechanical planarization (CMP) to near-atomic flatness. The particle size distribution (PSD) of the abrasive particles is a key factor in the CMP process due to its connection with polishing efficiency and defect creation on wafers during polishing. In this presentation the utility of a single-molecule spectroscopic technique, fluorescence correlation spectroscopy (FCS), in this application is described. FCS stands out among PSD analysis methods based on its sensitivity to particles with hydrodynamic diameters in the sub-10 nm size range. Characterization of abrasive particles of smaller size in CMP slurries has become a requirement as the feature sizes of integrated circuits steadily decrease according to Moore’s law. The use of FCS in conjunction with a complementary technique, particle tracking using the Viewsizer 3000 multi-laser Nanoparticle Tracking Analysis (m NTA), is described as an approach to meet this challenge.

Laser diffraction is the most popular technique for sizing CMP slurries owing to its fast, accurate, and precise measurements of both the nano- and micro-scale particles. The LA-960V2 Particle Size Analyzer can accurately measure particles from 10 nanometers to 5,000 microns, making this system an obvious choice for CMP applications. Our recent study to quantify the ability of the LA-960V2 to find a small number of oversize particles in the presence of the main population at 31 nanometers proves this point.

In this webinar we will first review and discuss the importance of the iso-electric point of metal-oxide polishing agents and the role of slurry pH and then we will examine the effect of slurry fluid chemistry using ZP measurements to characterize the chemically-modulated development of surface charge of such polishing agents during aqueous polishing.

The SZ-100V2 Nanoparticle Analyzer system uses dynamic light scattering has one advantage over laser diffraction: the ability to measure sub-100 nanometer particles at very low sample loading (particle concentration). After the presence of any destructive large particles has been verified, CMP test labs may add a DLS system to complement existing technologies for characterization of the smallest particles.

Simultaneous Multi-Laser Nanoparticle Tracking Analysis (NTA)

Laser Scattering Particle Size Distribution Analyzer

Laser Scattering Particle Size Distribution Analyzer

Advanced stand-alone AFM

In-Line Spectroscopic Ellipsometer for Web Coater and Roll to Roll Systems

Nanoparticle Analyzer

Vapor Concentration Monitor

Micro Volume pH Monitor

Do you have any questions or requests? Use this form to contact our specialists.