CMP(Chemical Mechanical Plashing)는 화학 산화 및 기계적 마모를 사용하여 재료를 제거하고 매우 높은 수준의 평면성을 달성하는 강력한 제조 기술입니다.

화학적 기계적 평탄화는 반도체 제조에서 지형 평탄화 및 소자 구조 형성을 위한 재료를 선택적으로 제거하기 위해 광범위하게 적용되어 왔습니다.

선택적 물질 제거는 고유한 화학 제형과 다수의 연마 입자를 포함하는 슬러리와 함께 화학 반응 및 기계적 마모를 사용함으로써 달성됩니다.

연마 중에 화학 반응 생성물과 기계적 마모 부스러기가 발생합니다. 슬러리 입자 및 연마 부산물은 웨이퍼 표면에 압착됩니다. 폴리셔에서 클리너로 웨이퍼를 이송하는 동안 웨이퍼 표면에 오염물질이 부착됩니다. 스크래치, 워터마크, 표면 거칠기, 부식, 유전체 상수 이동 없이 다양한 기하학적 특징에서 표면, 화학적, 기계적 특성이 다른 웨이퍼에서 입자, 유기 잔류물, 금속 오염물을 제거하기 위해 CMP 후 세척이 필요하합니다.

HORIBA는 CMP 프로세스에 대해 다음과 같은 분석을 제공할 수 있습니다.

Chemical mechanical polishing (or planarization) is the most popular technique for removing the surface irregularities of silicon wafers. Typical CMP slurries consist of a nano-sized abrasive dispersed in acidic or basic solution. A chemical reaction softens the material during mechanical abrasion. The abrasive particles have a size distribution which directly affects critical metrics including rate of removal and wafer defects. Particle size analysis is therefore a key indicator of CMP slurry performance.

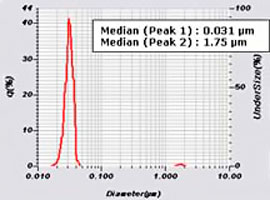

The typical size range of CMP abrasive particles is 50-250 nanometers and several particle sizing techniques are capable of measuring in this range with varying accuracy and precision. The typical oversize aggregate in CMP slurry is 1-10 microns and appears in the ppm range. The particle characterization challenge comes from the combination of accurately sizing the nano-scale particles while also identifying a relative few micron-scale aggregates.

Fine Particle Characterization in Chemical Mechanical Planarization (CMP) Slurries with Fluorescence Correlation Spectroscopy

with Prof. Edward E. Remsen | Bradley University, Mund-Lagowski Department of Chemistry & Biochemistry

and Tim Holt Applications Lab Manager | HORIBA Instruments, Semiconductor Segment

Fabrication of commercial integrated circuits depends critically on the physical and chemical properties of the abrasive slurry particles used to polish silicon wafer surfaces via chemical-mechanical planarization (CMP) to near-atomic flatness. The particle size distribution (PSD) of the abrasive particles is a key factor in the CMP process due to its connection with polishing efficiency and defect creation on wafers during polishing. In this presentation the utility of a single-molecule spectroscopic technique, fluorescence correlation spectroscopy (FCS), in this application is described. FCS stands out among PSD analysis methods based on its sensitivity to particles with hydrodynamic diameters in the sub-10 nm size range. Characterization of abrasive particles of smaller size in CMP slurries has become a requirement as the feature sizes of integrated circuits steadily decrease according to Moore’s law. The use of FCS in conjunction with a complementary technique, particle tracking using the Viewsizer 3000 multi-laser Nanoparticle Tracking Analysis (m NTA), is described as an approach to meet this challenge.

Laser diffraction is the most popular technique for sizing CMP slurries owing to its fast, accurate, and precise measurements of both the nano- and micro-scale particles. The LA-960V2 Particle Size Analyzer can accurately measure particles from 10 nanometers to 5,000 microns, making this system an obvious choice for CMP applications. Our recent study to quantify the ability of the LA-960V2 to find a small number of oversize particles in the presence of the main population at 31 nanometers proves this point.

In this webinar we will first review and discuss the importance of the iso-electric point of metal-oxide polishing agents and the role of slurry pH and then we will examine the effect of slurry fluid chemistry using ZP measurements to characterize the chemically-modulated development of surface charge of such polishing agents during aqueous polishing.

The SZ-100V2 Nanoparticle Analyzer system uses dynamic light scattering has one advantage over laser diffraction: the ability to measure sub-100 nanometer particles at very low sample loading (particle concentration). After the presence of any destructive large particles has been verified, CMP test labs may add a DLS system to complement existing technologies for characterization of the smallest particles.

멀티 레이저 나노 입자 추적 분석기

레이저 산란 입자 크기 분포 분석기

레이저 회절 입도 분포 분석기

In-Line Spectroscopic Ellipsometer for Web Coater and Roll to Roll Systems

나노입자 분석기

마이크로 볼륨 pH 모니터

HORIBA제품의 자세한 정보를 원하시면, 아래의 양식에 내용을 입력을 부탁드립니다.