Application

Chassis Dynamometer VULCAN

Overview

Evolution of Design

HORIBA continues to accumulate substantial knowledge in designing and manufacturing high-quality chassis dynamometers for the automotive industry in compliance with existing and forthcoming emission standards. Continuous optimization and improvement of the tried-and-tested design have led to the latest generation of VULCAN dynamometers. While creating this new range of chassis dynamometers, the HORIBA team reexamined fundamental design elements that are crucial to the performande demanded by our users. The digital force and speed measurement designs are characterized by their high accuracy and repeatability. Automated quality checks and product diagnostics additionally contribute to the performance of the overall system.

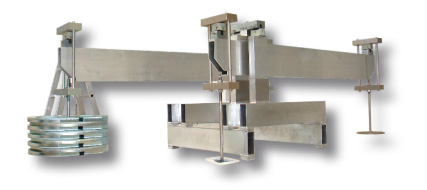

To advance the quality of the measurement results, HORIBA has improved calibration and measurement accuracy as well as the roller dimensions, enabling it to comply with current and future vehicle demands. A standard calibration device using a two arm design for full force calibration through the zero point assures easy and reliable calibration.

Features

- Highly accurate force and speed measurement (force repeatability typ. ± 0.005 % f.s.)

- Extended speed range up to 270 km/h available

- Zero warm-up time

- Convenient packaging allows easy retro-fitting into existing sites and future upgrades

- Remote maintenance for advanced system diagnostics

- Unique, easy-to-use two arm design calibration tool for full force calibration through the zero point

- Wheelbase range extendable to up to 4,400 mm

- Increased system and measurement reliability thanks to routine and preventative maintenance programs and built-in quality checks

- Wide range of optional features available

Key Features of Latest Generation

Modular Design

The latest generation of HORIBA VULCAN Chassis Dynamometers is characterized by a robust, modular design that offers improved performance, as well as increased flexibility and serviceability. The system is comprised of three pre-assembled and aligned main modules, a design which significantly reduces installation and maintenance costs. Numerous built-in functions in the area of diagnostics, calibration, handling, and vehicle parameterization are standard. Different AC power and roller inertias enable testing on a wide range of vehicles and applications, while the base-independent pit decking design ensures simple adaptation to various pit dimensions. In addition, VULCAN is easily upgraded from 2WD to 4WD applications.

SPARC VEHICLE Controller

The VULCAN system is equipped with the HORIBA SPARC VEHICLE Controller, including standard interfaces for emission host systems such as HORIBA’s market leading VETS system. In addition, HORIBA has made a number of improvements to this controller, which now offers various new features.

Main improvements of SPARC VEHICLE Controller

- Road load simulation via polynomial and multipoint functions

- Excellent friction loss compensation

- Parasitic loss measurement with coast down, ramping method and constant speed method

- Multiple user levels

- Operation response time measurement

- Support for three additional, vehicle-independent airstream blower sets

- Possible extensions, such as augmented braking, operating hour counter, etc.

Options

Extended Scope of Supply

HORIBA offers a number of optional packages for the new VULCAN system. To meet the requirements of various international legislation, roller surfaces with different coatings and roughness as well as different roller inertias are available. Extended temperature range packages provide functionality for testing in a temperature scope from -40 °C to +45 °C. Furthermore, HORIBA offers a large variety of driver’s aid systems, including test cycle definitions and an autopilot system.

Options

- Extended temperature range (-20 °C - +45 °C / -40 °C - +45 °C)

- Different roller surfaces and inertias to meet legislation requirements

- Extended speed range up to 270 km/h

- Centering device with lifting function

- Wheelbase range extendable to up to 4,400 mm

- Tire cooling and/or pit blowers

- Easy-to-use and time-saving wheel hub system

- Driver’s aid system including test cycle definition

- Autopilot system

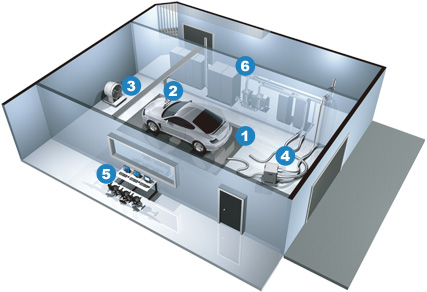

Chassis Dynamometer - Emission Measurement Application

1. 4WD chassis dyno

2. Drivers aid monitor

3. Air speed fan

4. Remote mix-T, RMT

5. Control room with VETS

6. Emission analysis equipment

Manufactured by HORIBA

Specifications

Standard | Options | |

|---|---|---|

Inertia | 1,150 kg | 1,360 kg |

Power | 155 kW / 170 kW (Overload) | 155 kW / 260 kW (Overload) |

Inner Roll Dimensions | 800 mm | |

Outer Roll Dimensions | 2,330 mm | |

Wheelbase | 1,800 mm – 3,400 mm | 1,800 mm – 4,400 mm |

Required Pit Depth | 2WD: 1,320 mm |