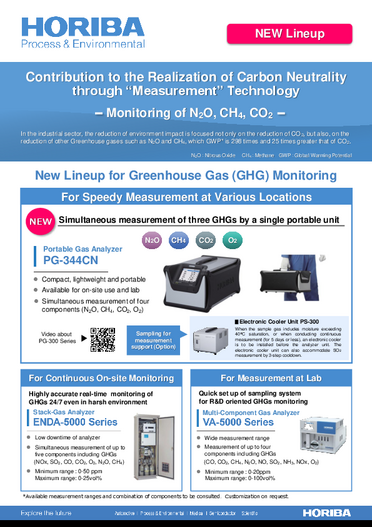

Nitrous Oxide Monitoring for Greenhouse Gas Reduction

Greenhouse gases (GHG), which are considered to be one of the causes of the global warming, include carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), and fluorinated gases.

In particular, various industries are required to reduce and manage the N2O emissions, which impact on the warming the atmosphere is 298 times that of CO2.

For example, sewage treatment plants generate N2O during sludge incineration treatment and during wastewater treatment in raw-water tanks and sludge storage tanks. Meanwhile, industrial waste treatment plants and garbage disposal plants generate N2O during incineration. Although N2O reduction has become increasingly common by adoption the latest equipment such as pyrolysis gasifying treatment, further reduction of N2O emissions is required through proactive monitoring.