CO₂ Separation/Capture and Storage/Sequestration

CO2 separation/capture and storage/sequestration to reduce CO2 emissions during manufacturing and power generation

To achieve carbon neutrality by 2050, extensive research and development are underway on carbon dioxide (CO2) adsorption materials and their evaluation systems. In the field of CO2 adsorption and separation materials R&D, various separation and recovery methods are employed depending on the source and concentration of CO2. It is essential to evaluate the performance and durability of these adsorption materials accordingly.

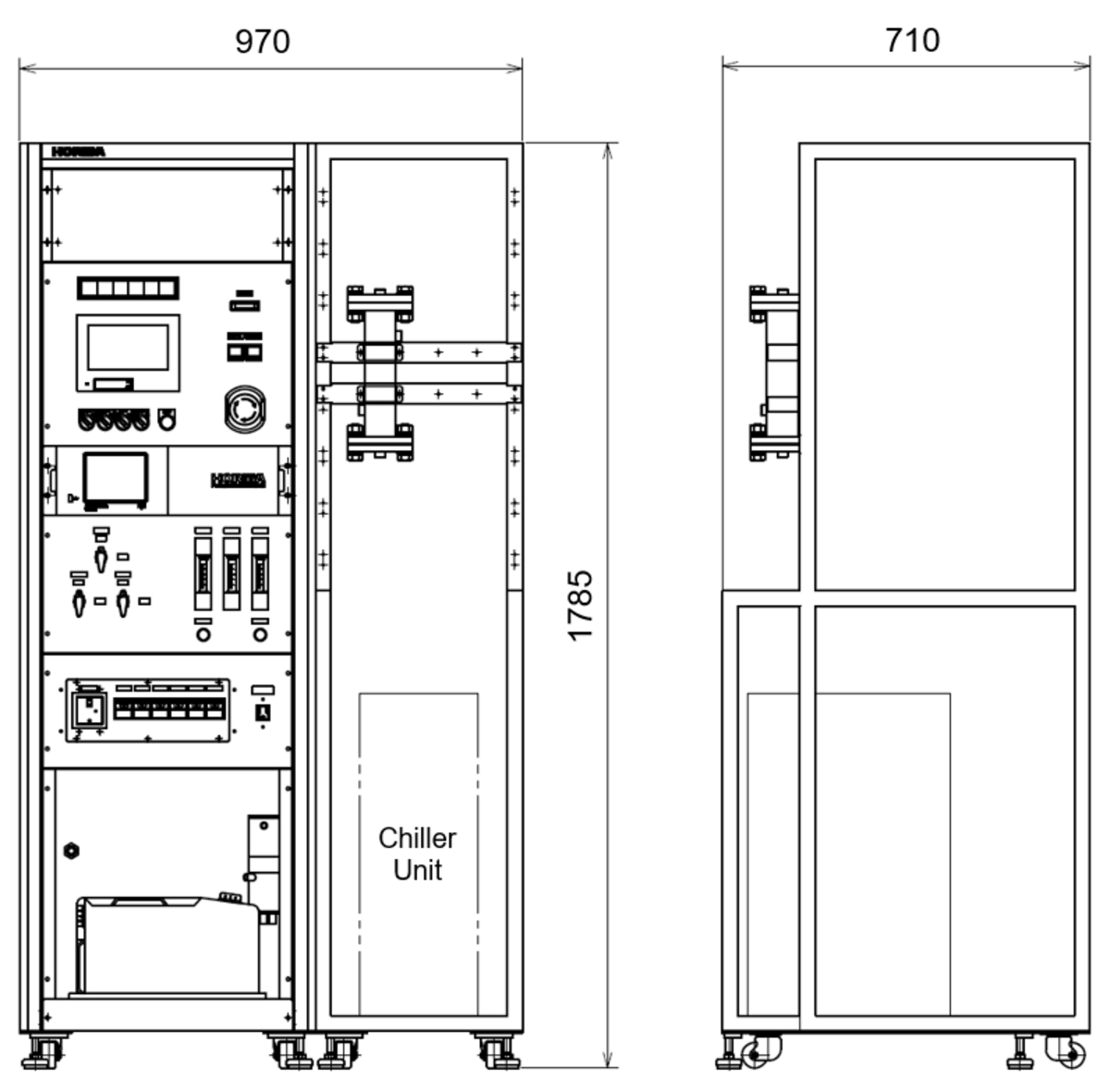

Figure 1: Carbon Capture Evaluation System CCEVA

| Analyzer | Up to 3 components incl. CO2 (optional) |

|---|---|

Number of flow path | 1 |

Flow rate range | 0.2 to 1 L/min |

Pressure range | -70 to +700 kPaG |

Chiller temperature control range | -20 to +150℃* |

Reactor tube dimensions | To be decided by meeting |

Mass flow controller | 2 to3units (N2 or Air, CO2) |

Humidification | Optional |

Injected gas | Up to 3 components(Optional) |

*The Chiller’s temperature control range may vary depending on the heat transfer liquid.

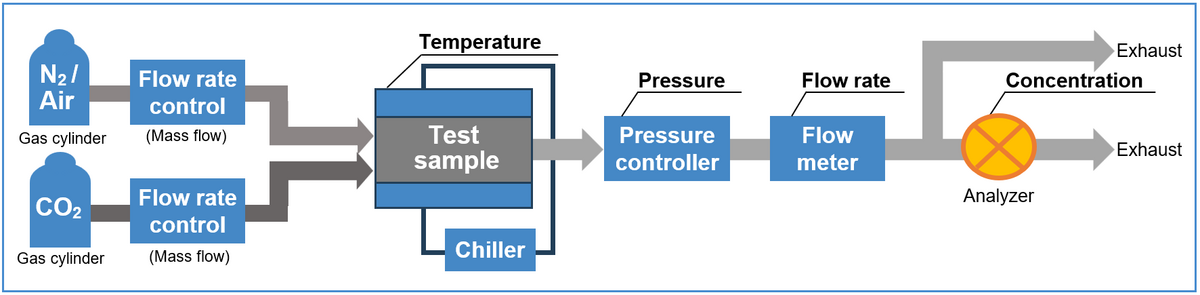

Image of Gas Flow

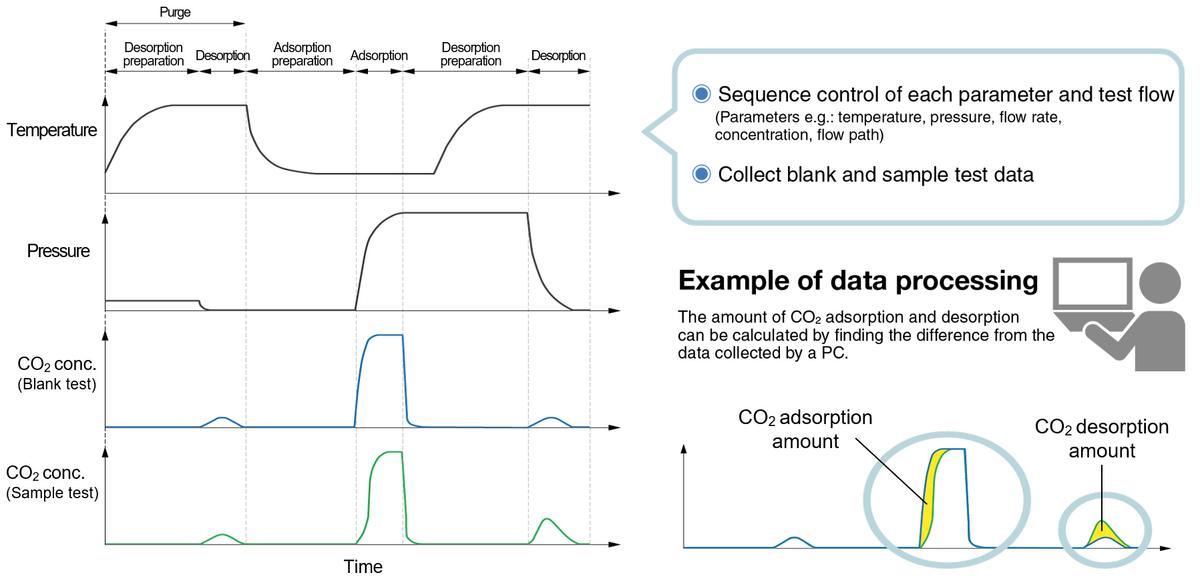

Ex. Measurement Data

*Appearance and dimensions may vary depending on the specifications.

Masz pytania lub prośby? Skorzystaj z tego formularza, aby skontaktować się z naszymi specjalistami.