Raman Imaging and Spectrometers

HORIBA is the world leader in Raman spectroscopy, with the benefits of more than 50 years of innovation in the technique.

<< Back to the Raman XPerience Newsletter articles

Correlative microscopy has become an essential methodology in modern materials science, nanotechnology, and life sciences. By combining complementary techniques, such as Raman spectroscopy, atomic force microscopy (AFM), scanning electron microscopy (SEM), transmission electron microscopy (TEM), focused ion beam (FIB-SEM), optical and super-resolution fluorescence imaging, scanning microwave microscopy (SMM), or scanning thermal microscopy (SThM), researchers can build a multidimensional understanding of structure, chemistry, functionality, and performance across scales.

However, as correlative workflows grow in complexity and ambition, a fundamental limitation increasingly emerges: the ability to reliably, reproducibly, and quantitatively relocate the exact same region of interest (ROI) across instruments, sessions, and laboratories.

While individual microscopy techniques have reached remarkable levels of resolution, sensitivity, and automation, correlative microscopy workflows often remain constrained by practical issues related to positioning:

In many workflows, correlation is performed a posteriori, relying on visual landmarks, surface features, or approximate coordinates. While sufficient for qualitative studies, these approaches quickly reach their limits when addressing quantitative structure-property relationships, regulatory-driven environments, or long-term studies requiring strict reproducibility.

Recent scientific works clearly illustrate both the necessity of correlative microscopy and the need for more robust, traceable positioning strategies.

Chibane, L., et al., Nanomaterials, 2025, 15, 1861.[1]

In their work on graphene oxide reduction, Chibane et al. propose a rigorous correlative metrology workflow combining AFM, SEM, Raman spectroscopy, SMM, and SThM on a single graphene oxide flake. The objective is not only to correlate morphology, chemistry, electrical, and thermal properties, but to do so without altering or damaging the sample during successive measurements.

This study highlights several critical constraints inherent to correlative microscopy at the nanoscale:

To address these challenges, the authors rely on lithographically patterned silicon substrates, which provide precise positioning references. While effective, this approach introduces notable limitations:

This case study clearly demonstrates both the scientific value of correlative metrology and the need for more flexible, substrate-independent positioning solutions.

O. Acher & al., Measurement Science and Technology, 2021, 32, 045402.[2]

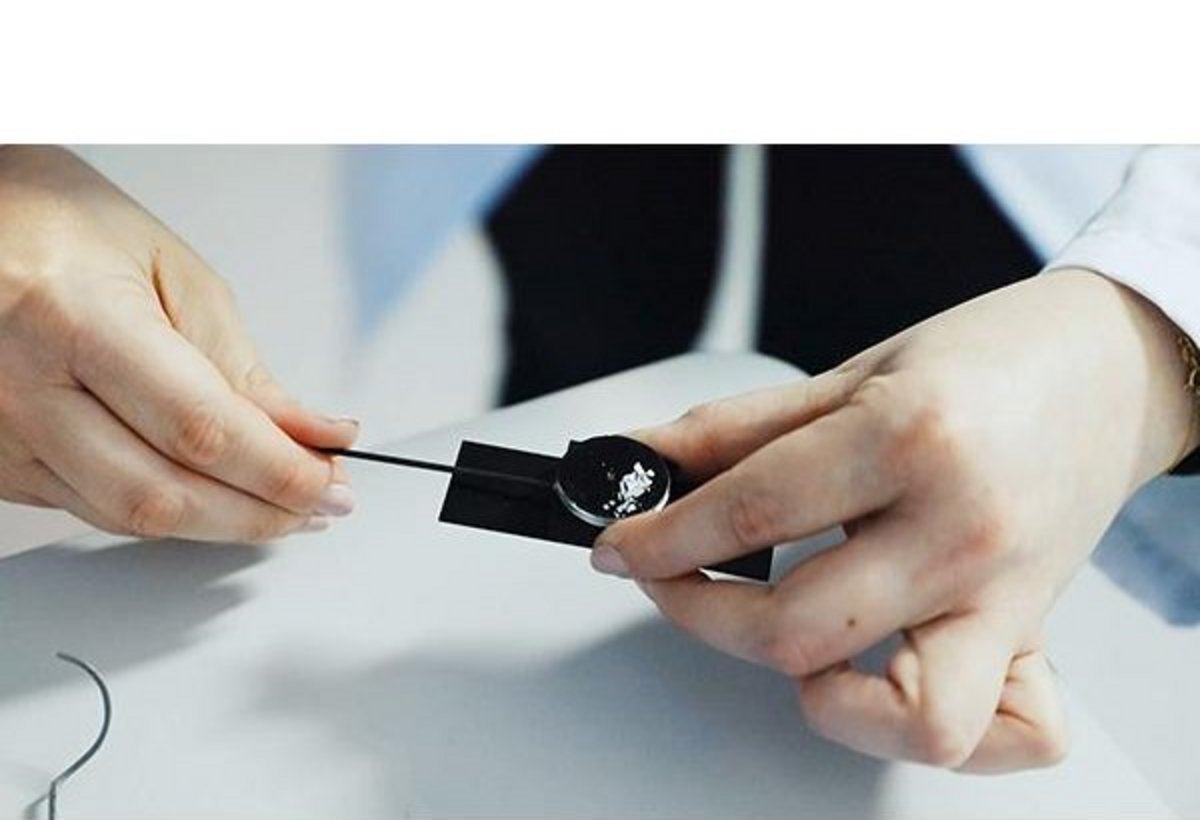

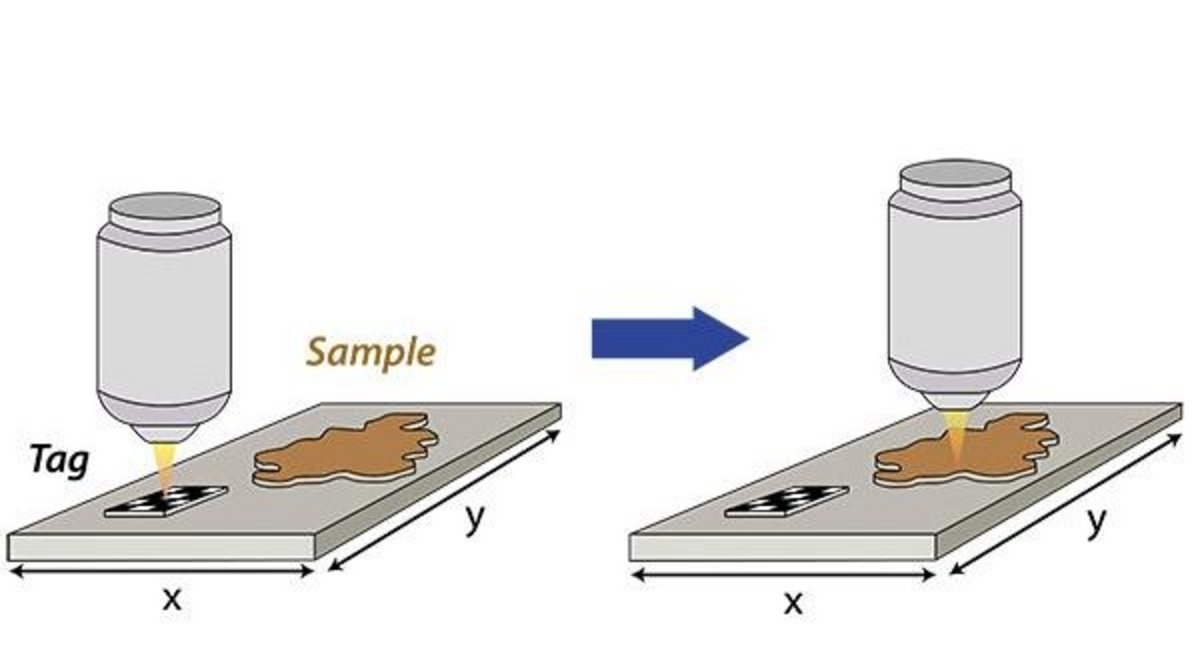

Acher et al. directly address these limitations by introducing machine-readable, multiscale, multimodal fiducial nanoGPS navYX tags as a metrology-driven backbone for correlative microscopy workflows.

Unlike conventional visual markers, nanoGPS navYX tags encode absolute position and orientation information. A single image of the tag—captured by SEM, optical microscopy, or Raman imaging—is sufficient to determine:

Key advantages demonstrated in this work include:

Relocation accuracies ranging from a few micrometers up to ~20 µm are achieved, enabling fast, unambiguous correlation without iterative manual alignment. This approach effectively transforms correlative microscopy from a qualitative alignment exercise into a traceable, quantitative, and reproducible analytical workflow.

L. Sotelo & al., Advanced Materials Technologies, 2023, 8, 2300126.[3]

The importance of robust correlative workflows is further illustrated by Sotelo et al. in their study on laser-induced periodic surface structures (LIPSS) on TiAl6V4 alloys for biomedical applications.

This work investigates how initial surface roughness and laser fluence influence:

To establish meaningful correlations, the authors combine SEM, AFM, Raman spectroscopy, and contact angle measurements on identical surface regions. Such studies critically depend on:

The study demonstrates that even subtle misalignment or sample alteration can compromise the interpretation of structure–function relationships. It therefore exemplifies the growing need for robust, repeatable, and traceable correlative positioning, especially in application-driven research such as biomedical implants.

Taken together, these studies reveal a clear evolution in correlative microscopy: Correlation is no longer sufficient, traceability, uncertainty control, and reproducibility are becoming essential.

As correlative workflows move toward:

they increasingly require metrology-grade positioning strategies that decouple correlation quality from operator skill, substrate constraints, and trial-and-error alignment.

By combining advanced multimodal instrumentation with traceable positioning technologies such as fiducial nanoGPS tags, correlative microscopy can evolve into a reliable, scalable, and quantitative analytical framework, unlocking deeper insights across nanomaterials, advanced materials, and life sciences.

Watch this webinar to discover practical workflows for traceable alignment, drift correction, and multimodal data fusion using nanoGPS navYX technology.

[1] Chibane, L., Delvallée, A., Fleurence, N., Douri, S., Morán-Meza, J., Ulysse, C., ... & Flahaut, E. (2025). Toward a Correlative Metrology Approach on the Same 2D Flake: Graphene Oxide Case Study—Sample Preparation and Stability Issues. Nanomaterials, 15(24), 1861.

[2] Acher, O., Nguyên, T. L., Podzorov, A., Leroy, M., Carles, P. A., & Legendre, S. (2021). An efficient solution for correlative microscopy and co-localized observations based on multiscale multimodal machine-readable nanoGPS tags. Measurement Science and Technology, 32(4), 045402.

[3] Sotelo, L., Fontanot, T., Vig, S., Herre, P., Yousefi, P., Fernandes, M. H., ... & Christiansen, S. (2023). Influence of Initial Surface Roughness on LIPSS Formation and Its Consecutive Impact on Cell/Bacteria Attachment for TiAl6V4 Surfaces (Adv. Mater. Technol. 12/2023). Advanced Materials Technologies, 8(12), 2370056.

Do you have any questions or requests? Use this form to contact our specialists.