Browse all HORIBA Products

Conductivity Standard Solution

Conductivity Standard Solution

Conductivity Standard Solution

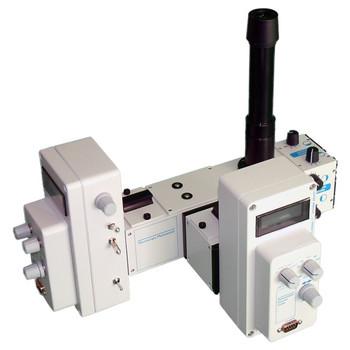

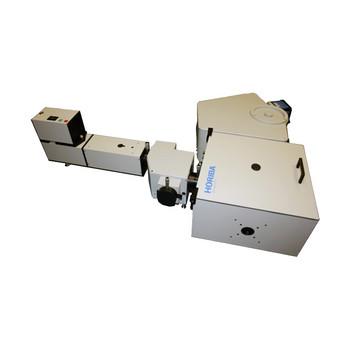

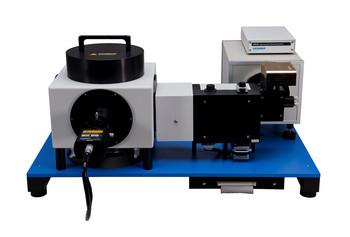

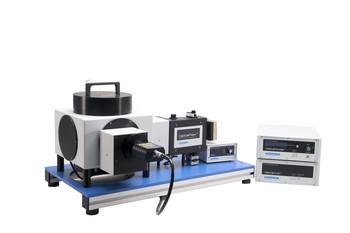

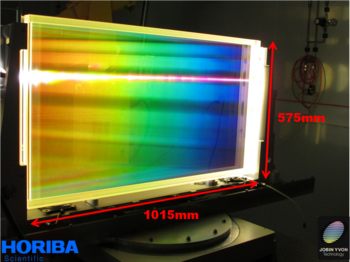

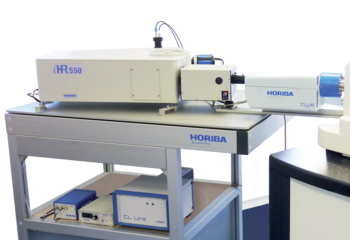

Long Focal Length Spectrometer

Conductivity Standard Solution

Conductivity Standard Solution

Conductivity Standard Solution

Conductivity Standard Solution

ORP Sensor Cartridge for WQ-300 series

Conductivity Standard Solution

Conductivity Standard Solution

Conductivity Standard Solution

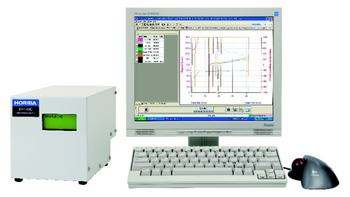

Explosion-proof Gas Analyzer

Gel-filled Self-Cleaning pH Electrode

Plastic body Non-refillable ORP electrode

Conductivity Cell for Ultra Pure Water Measurement

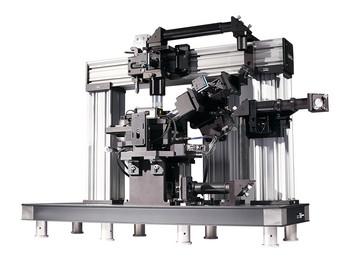

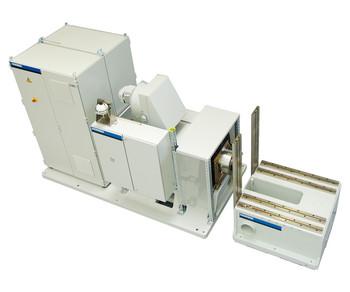

Automatic Driving System

pH meter with automatic calibration function

Dynamic Image Analysis

Air Pollution Monitor

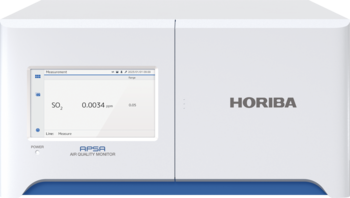

Air Quality Monitor

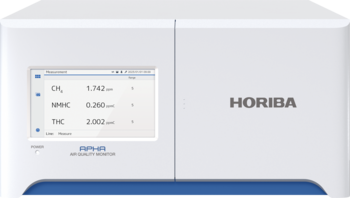

Hydrocarbon Monitor

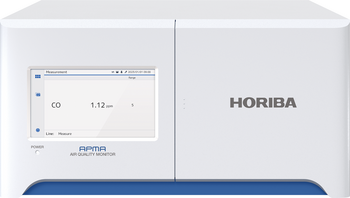

Carbon Monoxide Monitor

Air Pollution Multigas Calibrator

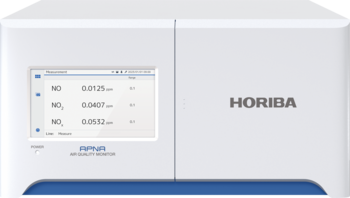

Nitrogen Oxides Monitor

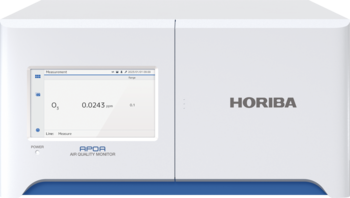

Ozone Monitor

Sulfur Dioxide Monitor

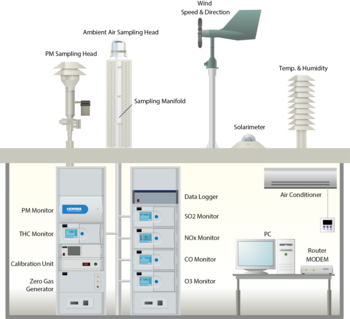

Ambient Air Quality Monitoring System

A Simple, Fast, “Column Free” Molecular Fingerprinting Technology

The Gold Standard for Water CDOM Research

Automated Organic Analysis & Early Warning Sentinel

Automatic Span Gasgenerator Unit

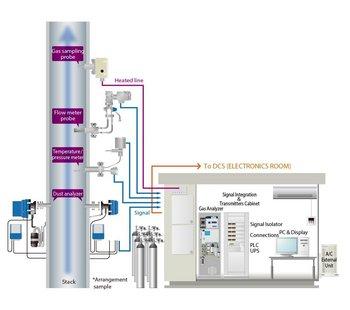

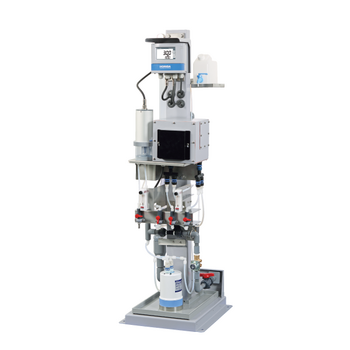

Sampling System

Spectroscopic Ellipsometer for Simple Thin Film Measurement

Global Hematology Solution

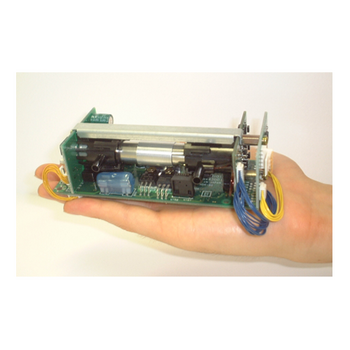

OEM gas (CO/HC) analyzer

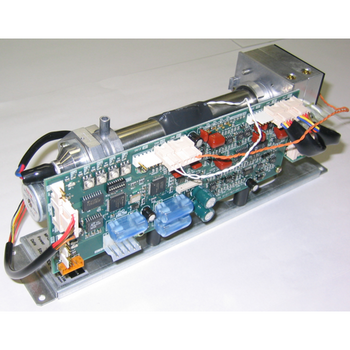

OEM gas (NO) analyzer

25-ton (22.7 metric ton) air-actuated laboratory pellet press.

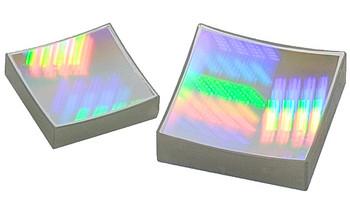

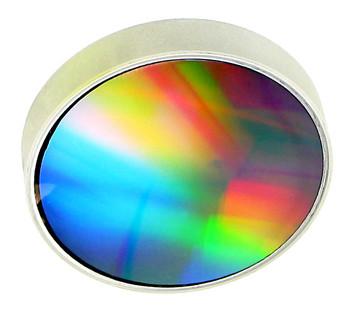

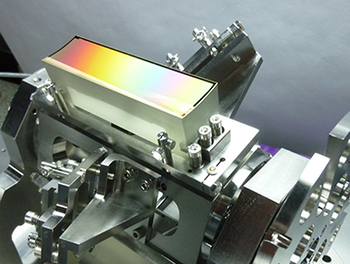

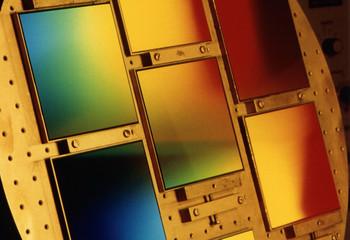

OEM gratings design and production capabilities

Cathodoluminescence Solutions for Electron Microscopy

Online Gas Analyser

Online Gas Analyser

Online Gas Analyser

Continuous Emission Monitoring System

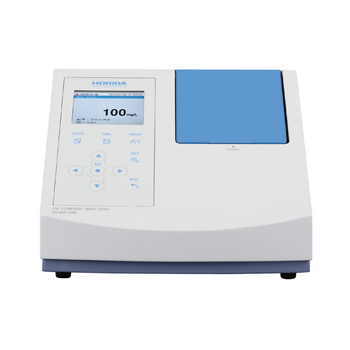

Automatic COD monitor

AFM and inverted light microscopy

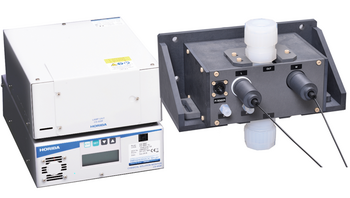

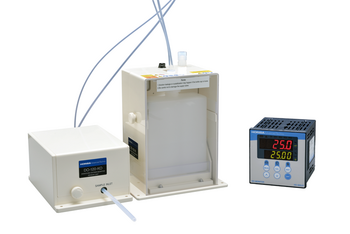

Single Channel Controller of Hot Block

Flexible Turn Key Solution for Test Beds

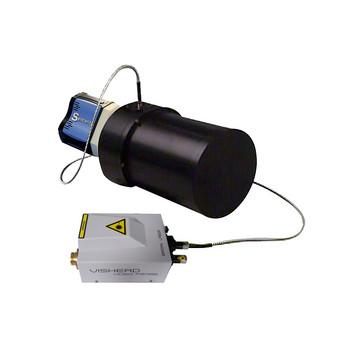

Dual Mode Analog/Photon Counting PMT

OEM miniature spectrograph

Forensic Light Source

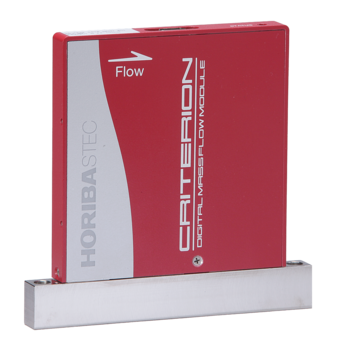

Pressure Insensitive Mass Flow Module

Large cryogenic mill that accommodates sample sizes ranging from 0.1 - 100 grams.

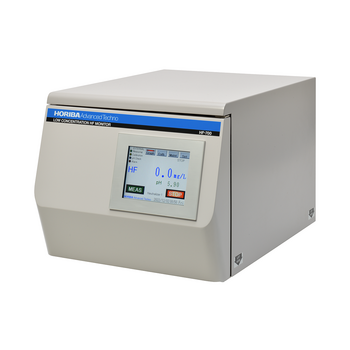

Stand-alone Type Chemical Concentration Monitor

Fiber Optic Type Chemical Solution Concentration Monitor

Fiber Optic Type Chemical Concentration Monitor

Optical Fiber Type Hot Phosphoric Acid Concentration Monitor

High Precision, High Stability Chemical Concentration Monitor

Non-Contact Chemical Concentration Monitor

Constant Volume Sampler

High Speed & Precision Pressure Insensitive Mass Flow Module

Best Performance Pressure Insensitive Mass Flow Module

Micro Flow Pressure Insensitive Mass Flow Module

Wide Range Pressure Insensitive Mass Flow Module

TCSPC Pulsed Sources

TCSPC/MCS Fluorescence Lifetime System

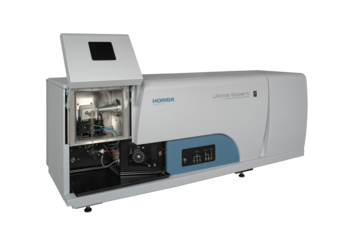

TCSPC Lifetime Fluorometer

Random Access Monochromator

Swing mill that accommodates sample sizes ranging from 2 - 100 grams.

Swing mill with sound-proof enclosure that accommodates sample sizes ranging from 2 - 100 grams

Hydraulic Dynamometers

Fluorescence and Absorbance Spectrometer

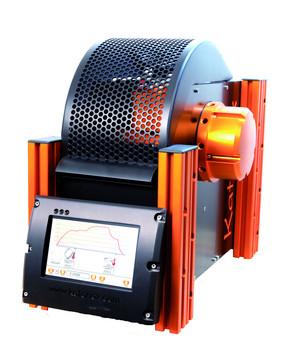

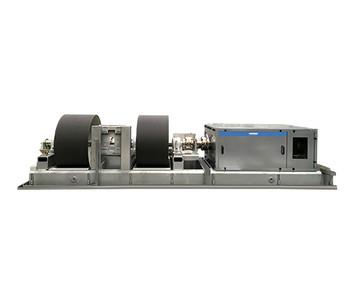

AC Dynamometer

Ultra-thin Mass Flow Module

Exhaust Pressure Controller

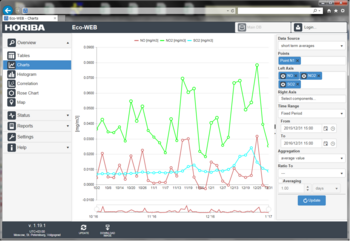

Data Management and Reporting Software

Washwater Monitoring System

Mono & Multi-Channel Water Controller

Multi-Channel Water Controller

Hydrogen Analyzer

Oxygen/Nitrogen/Hydrogen Analyzer

(Flagship High-Accuracy Model)

Oxygen/Nitrogen Analyzer (Entry Model)

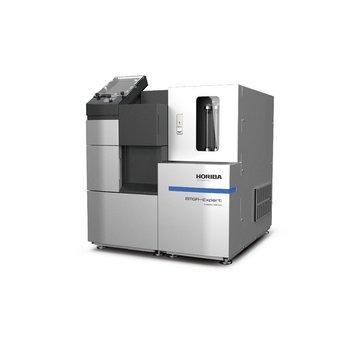

Carbon/Sulfur Analyzer

(Flagship High-Accuracy Model)

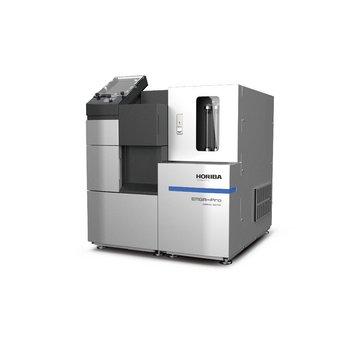

Carbon/Sulfur Analyzer (Entry Model)

Carbon/Sulfur Analyzer (Tubular Electric Resistance Heating Furnace Model)

Stack Gas Analysis System

Stack Gas Analyzer

Engine Torque Pulse Simulation

Endpoint / Chamber Health Monitor based on Optical Emission Spectroscopy and MWL Interferometry

Optical Emission Spectroscopy Etching End-point Monitor

Ultrasonic Exhaust Flow Meter

Online Gas Analyser

Online Gas Analyser

Online Gas Analyser

卓上型pHメータ

Compact Hyperspectral Cathodoluminescence

High Resolution Monochromators

OEM gratings design and production capabilities

SPAD array imaging camera for dynamic FLIM studies at real time video rates

Modular Research Fluorometer for Lifetime and Steady State Measurements

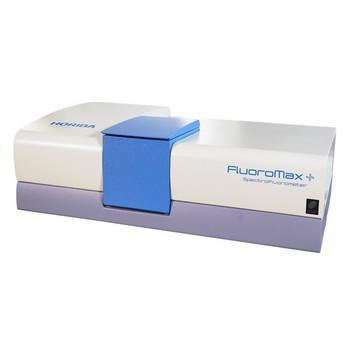

Steady State and Lifetime Benchtop Spectrofluorometer

Forensic Light Source

Fuel Flow Measurement Systems

Small cryogenic mill that accommodates sample sizes ranging from 0.1 - 4 grams.

Thermal Flow Splitter

FTIR Exhaust Gas Analyzer Dilute Measurement Type

FTIR Exhaust Gas Analyzer Direct Measurement Type

Trace Gas Monitor

Discover a Whole New World of Information with Glow Discharge Optical Emission Spectrometer

Double monochromator

High-throughput tissue homogenizer with an adjustable clamp.

Automated Tissue Homogenizer

Stack Gas Analyzer

Multi-Purpose Brake Dynamometers

Brake Test Systems

Brake Test Systems

Wafer Back Side Cooling System

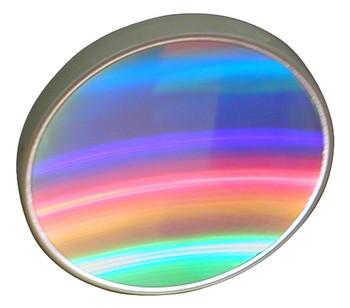

Pulse compression gratings using holographic techniques

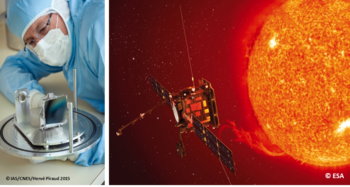

Space qualified and TRL9

Holographic Lamellar Gratings

Versatile Hyperspectral Cathodoluminescence

Imaging Scanning Monochromator

Field-installation Type Fluoride Ion Concentration Meter

Field-installation type ammonia nitrogen meter

Field-installation Type Fluoride Ion Concentration Meter

Field-installation type dissolved oxygen meter (DO meter)

Field-installation type optical dissolved oxygen meter (DO meter)

Field-installation type dissolved oxygen meter (DO meter)

Panel-mount type dissolved oxygen meter (DO meter)

HF (Hydrofluoric Acid) DO (Dissolved Oxygen) Monitor / Pure Water DO (Dissolved Oxygen) Monitor

Dissolved Oxygen Concentration Monitor Series for Semiconductor Manufacturing

High efficiency dedicated process Raman spectrometer for rugged and robust Raman monitoring.

Field-installation type electric conductivity meter (conductivity meter)

Field-installation type electric conductivity meter

Field-installation type electric resistivity meter (resistivity meter)

Field-installation type electrical conductivity meter (conductivity meter)

Field-installation type electric resistivity meter (resistivity meter)

Panel-mount type conductivity meter (conductivity meter)

Carbon Sensor Conductivity Meter (Low concentration type)

Panel-mount type conductivity meter (conductivity meter)

Panel-mount type resistivity meter (resistivity meter)

Resistivity Meter for Semiconductor Cleaning Processes

Citric Acid Monitor

Panel-mount type 2-channel conductivity meter (conductivity meter)

KOH Monitor

Phosphoric Acid Monitor

Wide range TMAH Concentration Monitor

High Precision TMAH Concentration Monitor

Carbon Sensor Conductivity Meter (High concentration type)

Panel-mount type conductivity meter

Carbon Sensor Conductivity Meter

Flat Carbon Sensor Conductivity Meter

Carbon Sensor Resistivity Meter

Panel-mount type 2-channel electric resistivity meter (resistivity meter)

2-Channel Resistivity Meter

Low Concentration Monitor- Sulfuric Acid/Hydrogen Peroxide

In-line Sensor & Auto Range Switching Concentration Monitor

HF / HCl Concentration Monitor

Low Concentration Type HF/HCl/NH3 Concentration Monitor

Field-installation type ORP meter

Field-installation type ORP meter

On-site, intrinsically safe explosion-proof ORP meter

Panel-mount type ORP meter

OEM gratings design and production capabilities

OEM gratings design and production capabilities

Field-installation type pH meter

Industrial pH meter

Field-installation type pH meter

Field-installation type intrinsically safe explosion-proof pH meter

Panel-mount type pH meter

Industrial pH meter

Panel-mount type pulse proportion control pH meter

Panel-mount type pH meter with industrial time sharing proportional control

Panel-mount type pH meter with 4-point alarm time sharing proportional control

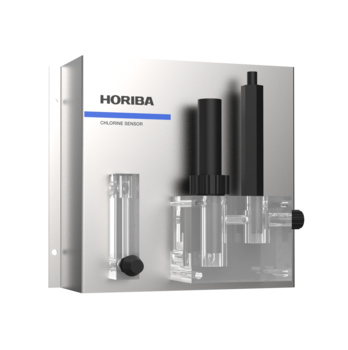

Field-installation type polarographic residual chlorine meter

Field-installation type residual chlorine meter

Panel-mount type galvanic residual chlorine meter

Panel-mount type polarographic residual chlorine meter

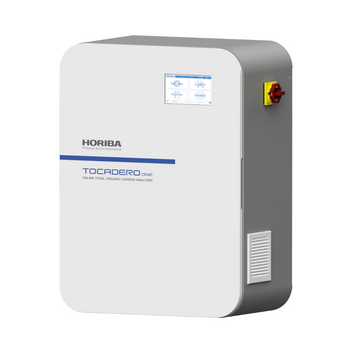

On-line TOC analyzer

Field-installation type color meter

Field-installation type MLSS meter

Field-installation type turbidity meter

Field-installation type turbidity meter

Field-installation type turbidity/SS meter

Field-installation type turbidity meter

HORIBA’s latest development in TCSPC detector technology

Hydrogen Gas Analyzer

Hydrogen Fuel Flow Meter

Hyperspectral Imaging Spectrometer Applications

Dissolved Ozone Monitor

H2O2 Monitor

Mid-Focal Length Imaging Spectrometers

Fluorescence Lifetime Imaging Platform

Ultra Compact and Broad Range Spectrometer

Datalogger IO-Expander

Vapor Concentration Monitor

High-grade type Gas Monitor for Chamber Cleaning End Point Monitoring

High-Accuracy Infrared Thermometer [Built-in type]

High-Accuracy Infrared Thermometer [Built-in type]

High-Accuracy Infrared Thermometers [Stationary type]

High-Accuracy Infrared Thermometers [Handheld type]

Confocal Raman & High-Resolution Spectrometer

AFM-Raman for physical and chemical imaging

Photoluminescence and Raman Wafer Imaging

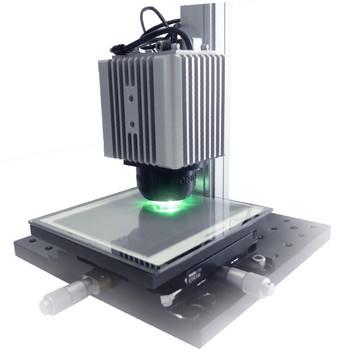

Raman Spectroscope - Automated Imaging Microscope

Real-time and Direct Correlative Nanoscopy

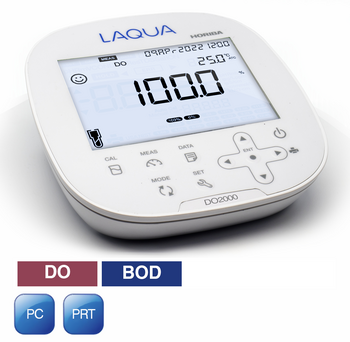

Benchtop DO/BOD/Temperature Meter

Handheld Dissolved Oxygen/Temperature Meter

Handheld Dissolved Oxygen/Temperature Meter

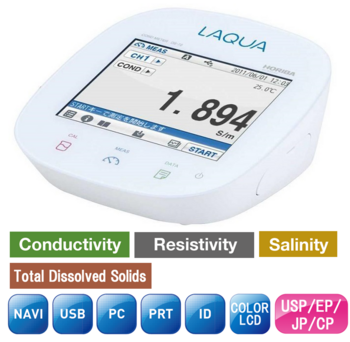

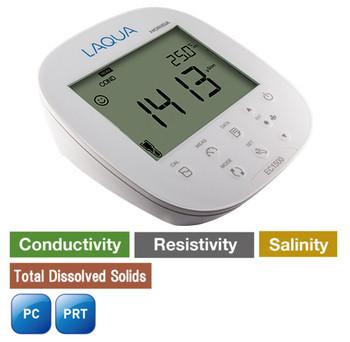

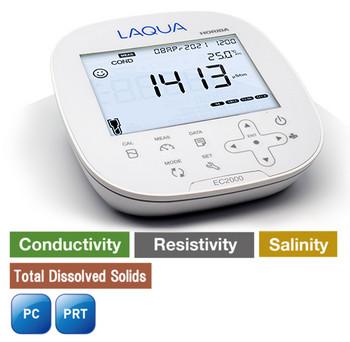

Benchtop Conductivity/Resistivity/Total Dissolved Solids/Salinity/Temperature Meter

Benchtop Water Quality Meters

Benchtop Conductivity Meter

Benchtop Conductivity Meter

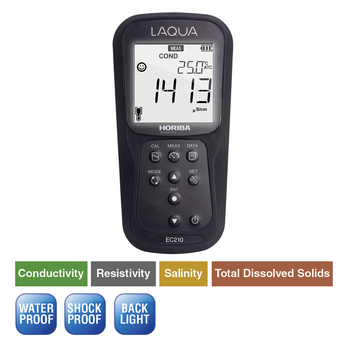

Handheld Conductivity/Resistivity/Salinity/Total Dissolved Solids/Temperature Meter

Handheld Conductivity/Resistivity/Salinity/Total Dissolved Solids/Temperature Meter

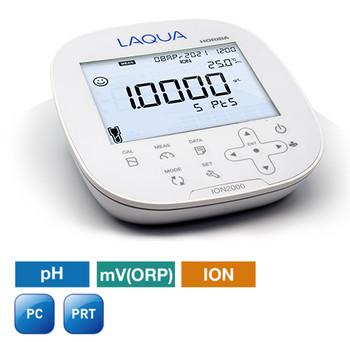

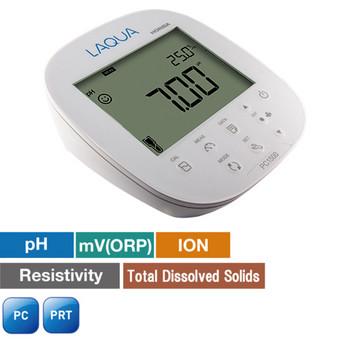

Benchtop pH/ORP/Ion/Temperature Meter

Benchtop pH/ORP/Ion/Temperature Meter

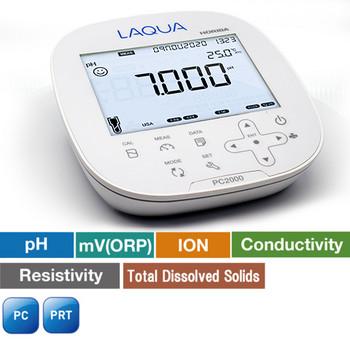

Benchtop pH/ORP/Ion/Conductivity/Resistivity/Total Dissolved Solids/Salinity/Temperature Meter

Benchtop pH/ION Meter

Benchtop Water Quality Meters

Benchtop pH/Conductivity Meter

Benchtop pH/ION/Conductivity Meter

Handheld pH/ORP/Conductivity/Resistivity/Total Dissolved Solids/Salinity/Temperature Meter

Handheld pH/ORP/Conductivity/Resistivity/Total Dissolved Solids/Salinity/Temperature Meter

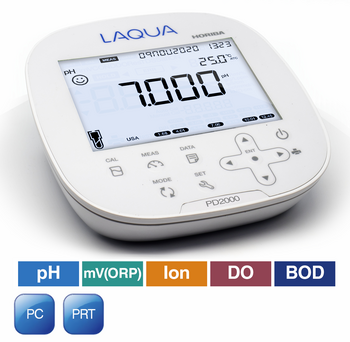

Benchtop pH/ORP/Ion/DO/BOD/Temperature Meter

Handheld pH/ORP/Dissolved Oxygen/Temperature Meter

Handheld pH/ORP/Dissolved Oxygen/Temperature Meter

Benchtop Water Quality Meters

Benchtop Water Quality Meters

Benchtop Water Quality Meters

Benchtop Water Quality Meters

Benchtop pH Meter

Handheld pH/ORP/Temperature Meter

Handheld pH/ORP/Temperature Meter

Handheld Water Quality Meters

Handheld Water Quality Meters

Handheld Water Quality Meters

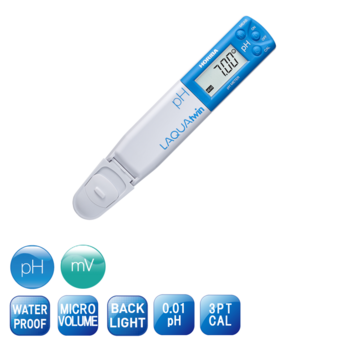

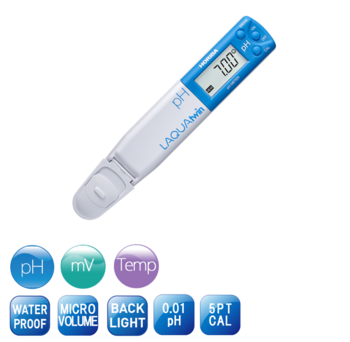

Pocket Water Quality Meters

Pocket Water Quality Meters

Pocket Water Quality Meters

Pocket Water Quality Meters

Pocket Water Quality Meters

Pocket Water Quality Meters

Pocket Water Quality Meters

Pocket Water Quality Meters

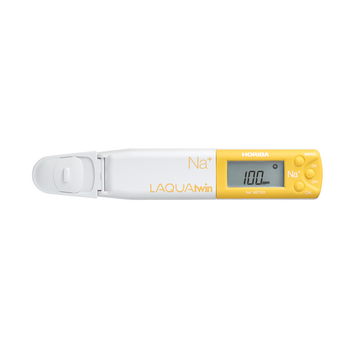

Pocket Water Quality Meters

Pocket Water Quality Meters

Pocket Water Quality Meters

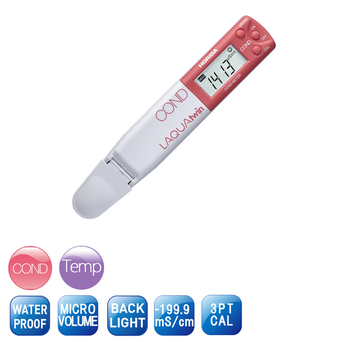

Pocket Water Quality Meters

Pocket Water Quality Meters

Pocket Water Quality Meters

Pocket Water Quality Meters

Large Flow Liquid Source Vaporization Control System

Camera Endpoint Monitor based on Real Time Laser Interferometry

Digital Liquid Mass Flow Meters / Controllers

Laser scanning oil film detector

Compact Baking System

Compact Deuterium, Tungsten Halogen or Glow Bar Light Source

Liquid Auto Refill System

High Sensitivity Imaging Spectrograph

Affordable Benchtop Raman Spectrometer

Full-size 12-ton (10.9 metric ton) Carver hydraulic laboratory pellet press.

Full-size 25-ton (22.7 metric ton) Carver hydraulic laboratory pellet press.

Bench top 12-ton (10.9 metric ton) Carver hydraulic laboratory pellet press.

Micro Dilution Tunnel

Dynamic Altitude Simulation

X-Ray Fluorescence Analyzer

X-Ray Fluorescence Analyzer

X-ray Fluorescence Sulfur/Chlorine-in-oil Analyzer

Heated Type NOx Analyzer

Heated Type THC Analyzer

Motor Exhaust Gas Sulfur Analyzer

Motor Exhaust Gas Analyzer

Solid Particle Counting System

Automotive Emission Analyzer

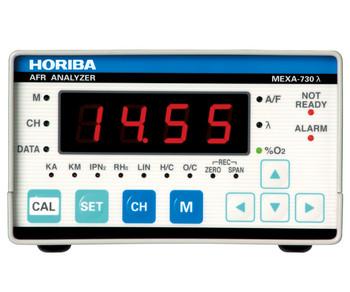

Air-to-fuel Ratio Analyzer

Motor Exhaust Gas Analyzer

FTIR Motor Exhaust Gas Analyzer

Laser Spectroscopic Motor Exhaust Gas Analyzer

Laser Spectroscopic Motor Exhaust Gas Analyzer

Mixed Injection System Liquid Vaporizers

Short Focal Length Imaging Spectrometers

Quadrupole Mass Analyzer

Hematology Analyzer

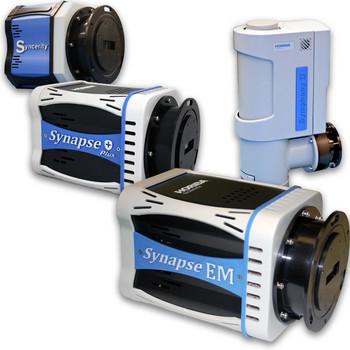

Ideal for Electrophysiology researchers to quantitate light intensity out of a microscope

Mini Raman Spectrometer

Compact High Resolution CMOS or CCD Spectrometer

Small high-energy ball mill that accommodates sample sizes ranging from 0.2 - 1.5 grams.

High-energy ball mill that accommodates sample sizes ranging from 0.2 - 10 grams.

Flexible Raman System

Affordable ultra-low frequency Raman spectrometer down to 10 cm-1

OEM gratings design and production capabilities

Mixed Gas Generators MU Series

Mixed Injection System Liquid Vaporizer

Collaborative Correlative Microscopy

X, Y, Θ Absolute Position Encoder

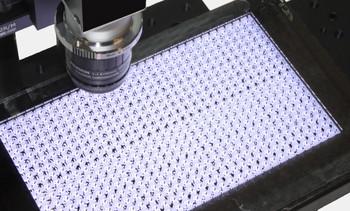

X, Y, Θ Position Calibration Plate For Machine Vision and Microscopy

Steady State and Lifetime Nanotechnology EEM Spectrofluorometer

Nanoparticle Analyzer

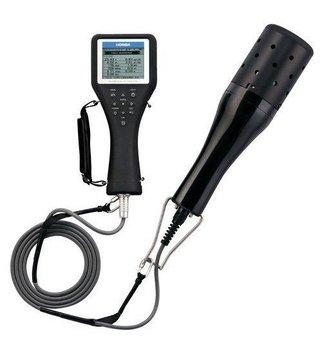

On-board Emissions Measurement System

On-board Emissions Measurement System

On-board Emissions Measurement System

On-board SPN10 measurement for real-world

On-board NH3/N2O Measurement System for real-world driving

Compact Spectrometer for OCT

Oil concentration meter

Oil concentration meter

Oil concentration meter

OEM Raman Filters

Only available for volume OEM purchase, minimum order quantity 50 units.

OEM Miniature Raman Systems and Components

UV-VIS-NIR Spectrometer

The AFM optical platform

Manual label-free molecular interaction analysis machine Flexible Research Platform

Organic pollutant monitor

Organic pollutant monitor

Choose from a large assortment of optical components for your custom spectroscopy solutions

Environmental Radiation Monitor "Radi"

Centrifugal Nanoparticle Analyzer

Laser Scattering Particle Size Distribution Analyzer

Laser Scattering Particle Size Distribution Analyzer

Hematology Analyzer

Hematology Analyzer

Clinical Chemistry Analyzer

Particulate Filter Management System

Portable Gas Analyzer

Portable Automated Measuring System

Self contained PMT housing for quantitative spectroscopy and imaging low light measurements

Process Laser Gas Analyzer

Peracetic acid concentration monitor

Multichannel Spectrometer and Hyperspectral Line Imager

Multispectra, Multifiber, Multichannel Imaging spectrometer with 8-16-32 Simultaneous UV-NIR Spectra

Multichannel Grating Spectrometer

Hyperspectral Imaging Spectrometer

DUAL & QUAD CCD Mini-Spectrometer

Broadband Xe Light Source

Single photons detection with picosecond accuracy

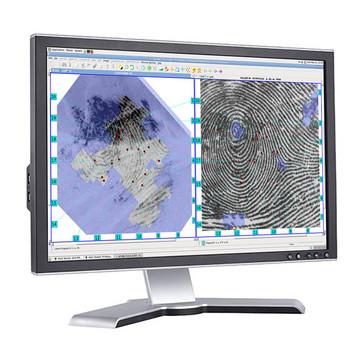

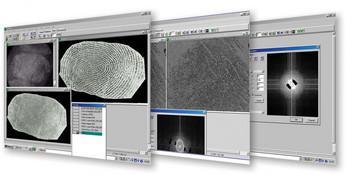

Automated Fingerprint and Palmprint Identification - AFIS & APIS Systems

Process Analyzer System

Scanning NV Magnetometry

Pitot Tube Exhaust Flow Meter

Dual Pitot Tube Exhaust Flow Meter

Piezo Actuator Valve

Continuous Particulate Monitor with X-ray Fluorescence

Hot Blocks for Acid Digestion

Close Vessel Microwave Digestion System

Automated Workstation

Close Vessel Microwave Digestion System

Raman Photoluminescence & Cathodoluminescence

Raman Spectrometers

MINI-CCT+ Mini Raman Spectrometer

Fiber coupled microscope

On-vehicle Ultrasonic Fuel Flow Meter

Reticle/Mask Particle Remover

Plasma Emission Controller

OEM gratings design and production capabilities

BET Surface Area Analyzers

Insertion sensor type for wide-range conductivity meter HE-960HI

Reflective Ultra Violet Imaging System

Deep Cooled UV/Vis/NIR

High Temperature Digital Mass Flow Controller

Mass Flow Controller

Digital Mass Flow Controller

Multi Range/Multi Gas Digital Mass Flow Controller

Pressure Insensitive Mass Flow Controller

Large cryogenic mill that accommodates sample sizes ranging from 0.1 - 100 grams.

Scanning Probe Microscope with Chemical Signature

Large choice of PMTs, solid state, photoelectric detectors for custom spectroscopy solutions

Interface level meter

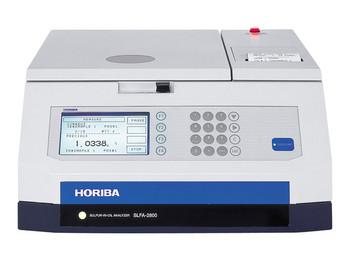

X-ray Fluorescence Sulfur-in-Oil Analyzer

X-ray Fluorescence Sulfur-in-Oil Analyzers

X-ray Fluorescence Sulfur-in-Oil Analyzer

X-ray Fluorescence Sulfur-in-Oil Analyzer

Highly sensitive silica monitor for ultra-pure water management in semiconductor/FPD processes

Silica analyzer

Powerful and Cost Effective Spectroscopic Ellipsometer

Advanced stand-alone AFM

Add Spectroscopy to ANY Microscope

Superior and Intelligent Controller Platform

Digital Controller

Solid Particle Counting System

LED Phosphorescence Light Sources

Laser-induced Breakdown Spectroscopy (LIBS)

Software Control and Data Acquisition

Software Solutions

Deep Cooled High Speed Scientific CMOS Camera

Ultra-compact Scientific Uncooled CMOS Camera

UV-VIS-NIR EMCCDs Camera

EMCCD Scientific Camera

Deep Cooled NIR Scientific Cameras

OEM CCD Camera

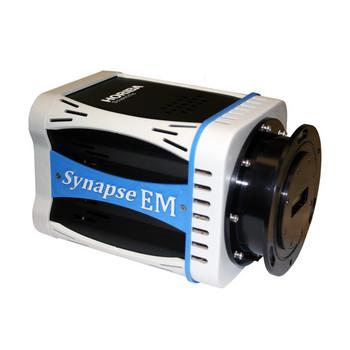

Deep Cooled UV/Vis/NIR and VUV Scientific Cameras

Deep Cooled Vacuum Ultra Violet Scientific Cameras

Hydrogen Gas Analyzer

PTFE Filter/TFH membrane

E-Motor Testing

Engine Test Stand System

Powertrain Testing for Front, Rear and All Wheel Drive

Automatic Total Organic Carbon Analyzer (On-line TOC analyzer)

Automatic total nitrogen/phosphorus monitor

Raman accessory for pharmaceuticals

Versatile AFM Optical Coupling

Test Gas Generation Systems

Tunable Broadband Light Sources

Tunable 75W Xe Light Source

Water distribution monitor

Water distribution monitor

Tunable Laser Gas Analyzer

Multi-parameter water quality checker

Ultra Fast TCSPC Lifetime Fluorometer

High resolution, high sensitivity and high stability ICP-OES

Affordable high performance ICP-OES

Micro Volume pH Monitor

Digital Automatic Pressure Regulator

for UV Raman spectroscopists

Online Water analyzer

Online Analyser for Drinking Water

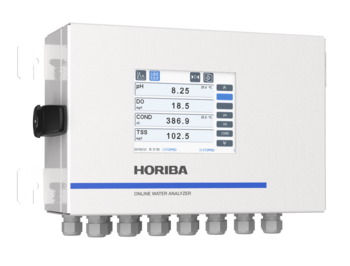

Online Water Analyzer

Online Water Analyser

Online Water Analyser

Online Water Analyser

Spectroscopic Ellipsometer from FUV to NIR: 190 to 2100 nm

Total Siloxane Analyzer

Multi-Component Gas Analyzer

Direct Liquid Injection System

Vapor Concentration Controller

Capacitance Manometer

Simultaneous Multi-Laser Nanoparticle Tracking Analysis (NTA)

Miniature High Throughput Spectrometer

High Spectral Rate and High Dynamic Range Miniature Spectrometers

Miniature Multi Communication UV-NIR Spectrometer

Highest SNR PDA Miniature Spectrometer

Miniature 18-Bit Spectrometer

Cost-effective, High-performance Mini Spectrometer

Most Compact Vacuum UV Back-Illuminated CCD Spectrometer (VUV-FUV)

Automated Hot Block

Chassis Dynamometer

Model Size System

Full Size System

8 hot blocks controlled by one wireless commander!

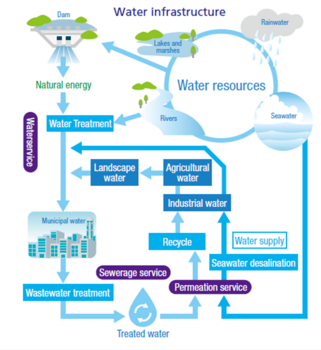

Water Quality Monitoring System

Eddy Current Dynamometers

Energy Dispersive X-ray Fluorescence Analyzer

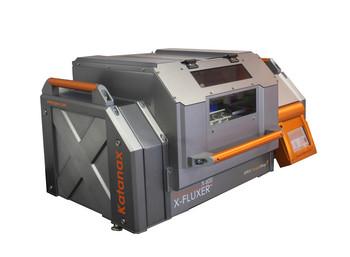

Six position electric Fluxer

35-ton (31.8 metric ton) hydraulic laboratory pellet press.

X-ray Analytical Microscope (Micro-XRF)

X-ray Analytical Microscope

with a Super Large Chamber

AFM-Raman for Physical and Chemical imaging

MicroRaman Spectrometer - Confocal Raman Microscope

Total Nitrogen and Sulfur Analyzer

Total Halogen and Sulfur Analyzer

Next Generation Total Nitrogen and Total Sulfur Analyzer

Clinical Chemistry Analyzer

Hemostasis Analyzer

Hematology Analyzer

Zero Gas Generator

![LAQUA EC1100 BenchMeters LAQUA EC1100 [No longer available]](http://static.horiba.com/fileadmin/Horiba/_processed_/7/4/csm_EC-1100_BenchMeters-HORIBA_9933ff65d8.png)

![LAQUA PC1100 BenchMeters LAQUA PC1100 [No longer available]](http://static.horiba.com/fileadmin/Horiba/_processed_/3/6/csm_PC1100_BenchMeters-HORIBA_d32a2ab4ec.png)

![LAQUA PH1100 BenchMeters LAQUA PH1100 [No longer available]](http://static.horiba.com/fileadmin/Horiba/_processed_/a/8/csm_PH1100_BenchMeters-HORIBA_becea9c3f1.png)

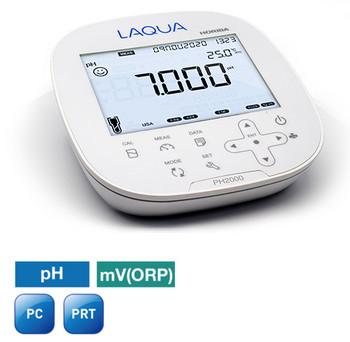

![LAQUA PH1200 BenchMeters LAQUA PH1200 [No longer available]](http://static.horiba.com/fileadmin/Horiba/_processed_/1/e/csm_PH1200_BenchMeters-HORIBA_9bcf1fdef7.png)

![LAQUA PH1300 BenchMeters LAQUA PH1300 [No longer available]](http://static.horiba.com/fileadmin/Horiba/_processed_/3/1/csm_PH1300_BenchMeters-HORIBA_bdb8a82d73.png)