<< Back to OEM Solutions for your Applications

The food, beverage, and agriculture industries face growing demands for quality control, safety assurance, and process optimization.

Optical sorting technologies and quality control help detect food composition, ensure product safety, and optimize precision agriculture. These techniques analyze soil conditions, assess food quality, and remove defective products from production lines.

However, implementing such advanced solutions presents challenges, including accuracy, speed, and adaptability to various environments. This is where Original Equipment Manufacturer (OEM) solutions become essential, providing tailored, high-performance spectroscopic modules to meet the industry's needs..

Sorting technologies ensure that food products meet strict quality and safety standards.

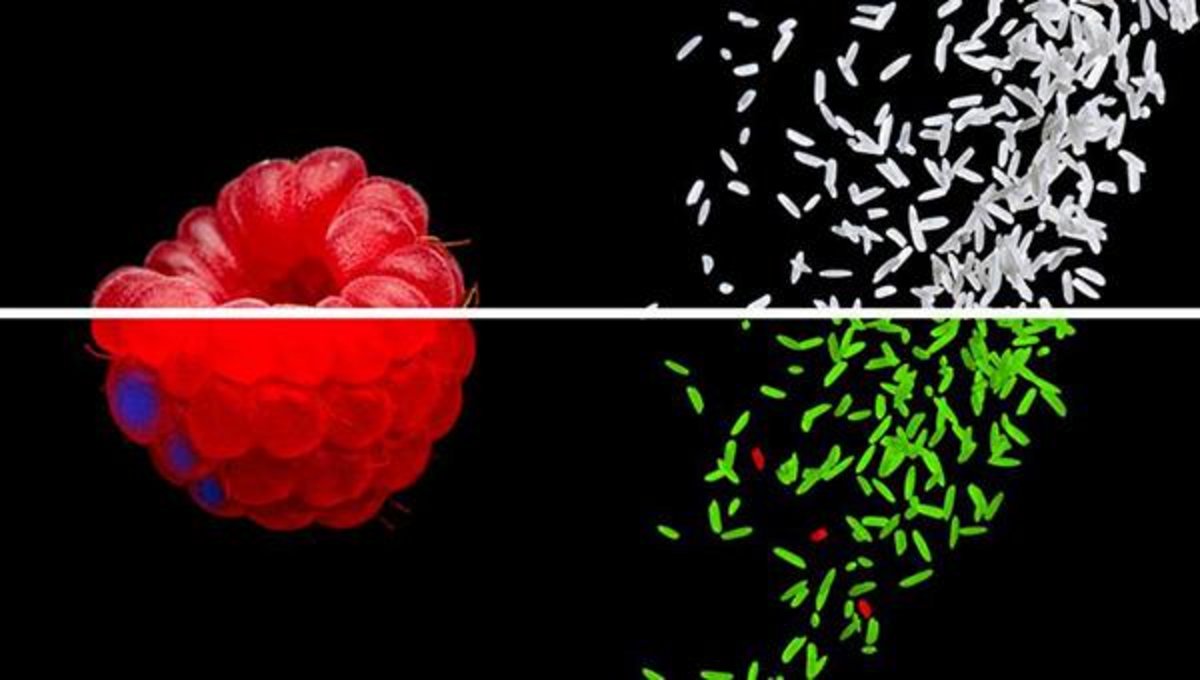

Spectroscopic methods help classify produce based on composition, purity, and contamination levels, identifying defects that are invisible to conventional imaging. For example, hyperspectral sorting can detect spoiled or contaminated products, ensuring food safety before distribution thanks to its high spectral and spatial resolution.

Challenges include maintaining high-speed detection, optimizing sorting accuracy, and integrating these OEM solutions into industrial workflows, offering robust spectroscopic tools for efficient, real-time food sorting and quality control.

Quality control leverages spectral analysis to monitor and optimize agricultural and food production processes. This enables the detection of food composition (e.g., protein and water content), the analysis of soil conditions, the monitoring of crop health, and more.

Optical spectroscopic solutions and hyperspectral cameras overcome these issues by analyzing hundreds of wavelengths in real time.

This technology, specifically working in the VIS NIR/SWIR spectral range, accurately detects internal flaws and subtle differences, enabling automated, non-destructive quality control. Such optical solutions can be integrated in laboratory, process or field equipments.

By delivering state-of-the-art sensors and spectroscopic solutions, HORIBA enables advanced optical sorting, enhancing operational efficiency and analytical accuracy across industries.

HORIBA’s hyperspectral and Vis-NIR/SWIR technologies play a critical role in ensuring product quality and safety, detecting contamination, and classifying produce based on composition and purity, even at high processing speeds.

Multichannel Spectrometer and Hyperspectral Line Imager

Imaging Scanning Monochromator

SPAD array imaging camera for dynamic FLIM studies at real time video rates

TCSPC Pulsed Sources

HORIBA’s latest development in TCSPC detector technology

Single photons detection with picosecond accuracy

Amplifier-Discriminator

Sie haben Fragen oder Wünsche? Nutzen Sie dieses Formular, um mit unseren Spezialisten in Kontakt zu treten.