Model | LU-A1000 series |

Liquids supported | TEOS, TMOB, TMOP, TEOP, BTBAS |

Supply method | Pressure movement from He gas |

Gas supply pressure | For pressure movement: 0.3 to 0.6 MPa (G); For purge: 0.3 to 0.6 MPa (G), OP N2 0.6 to 0.7 MPa (G) |

Tank | Maximum 5-gallon container can be attached (outside of production range) |

Operation | Automatic supply/stop using external signal from supply system |

Operation area display details | Pressure error display; When an alarm is triggered: Display hold function (manual reset); Liquid level display; Sequence, etc. |

Gas connection | Refer to basic flow |

Power source | AC 100 to 240 V, 50/60 Hz, 300 VA |

Electricity connection | AC 100 to 240 V breaker connection, signal receptacle |

External dimensions | See external dimensions diagram |

* Please make decisions regarding the specifications above after meeting with STEC. | |

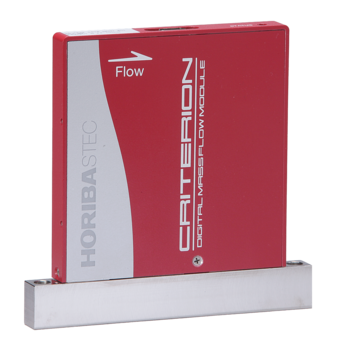

External Dimension

![]()

![]()

![]()