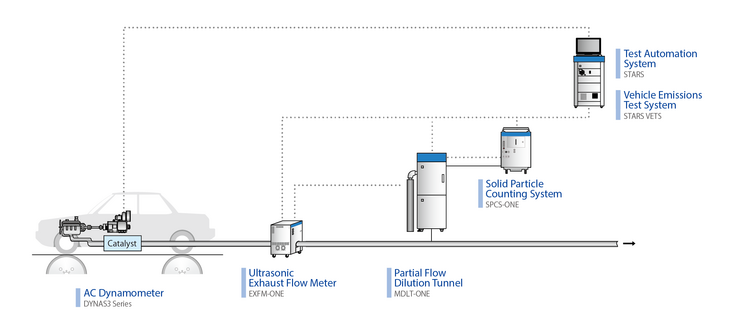

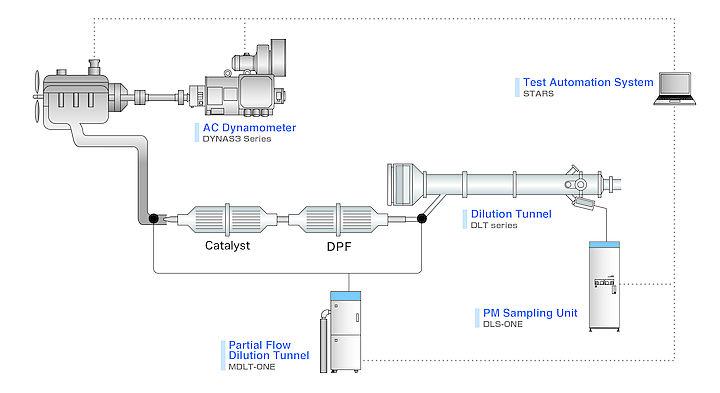

| System outline | ||||||

| PM sampling method | Partial flow dilution method | |||||

| Control modes for dilution | Proportional sampling mode (Const. split ratio)/ Fixed dilution ratio mode (Const. dilution ratio)/ Fixed flow rate mode (Manual control) | |||||

| Control methods for dilution | ・Real-time control based on analog input of exhaust flow rate ・Control based on learned pattern of exhaust rate | |||||

| Required signal for gas sampling | Isolated analog signal (0 to 10 V) | |||||

| Flow rate of diluted gas | 25 to 80 L/min*1 (under the condition of 20 °C and 101.3 kPa) | |||||

| Accuracy of dilution ratio | Within ± 5 % (Confirmed by measuring CO₂) When dilution ratio=15 rate at 20 °C and 101.3 kPa: 53 to 80 L/min | |||||

| PM mass calculation*2 | PM mass (in g/test or g/kWh) can be calculated and saved, based on integrated values of flow rated and dilution ratio. | |||||

| Configurations | ||||||

| System configuration | ・Main unit: Dilution-tunnel unit ・Operation unit: PC, monitor, keyboard and mouse (table is not included) | |||||

| Utilities | ・Purified air: for dilution gas, 400 to 700 kPa, oil free, at least 100 L/min (at 20 °C and 101.3 kPa) | |||||

| Power supply voltage and frequency | ・Main unit: 100/110/120/200/220/230/240 V AC, 50/60 Hz, single phase ・Operation unit: 100/110/120/200/220/230/240 V AC, 50/60 Hz, single phase | |||||

| Power requirements | Main unit: Max. 3.0 kVA / Operation unit: Max. 0.5 kVA | |||||

| Dimensions | ・Main unit: 570 (W) × 730 (D) × 1700 (H) mm ・Space for operation unit: 900 (W) × 500 (D) mm (table is not included) | |||||

| Mass | Main unit: Approx. 300 kg (excluding operation unit) | |||||

| Number of filter lines | Max. 6 lines (5 for sample, 1 for bypass) | |||||

| Type of filter holder | ・φ70 mm type: actual PM sampling area φ60 mm, with back-up filter ・φ47 mm type: actual PM sampling area φ38.8 mm*1, with back-up filter*1 | |||||

| Operating conditions | ||||||

| Sampling Pressure | Between atmospheric pressure and up to 40 kPa Back pressure of exhaust line: Less than 1 kPa | |||||

| Options | ||||||

| Filter auto-changer*3 | Changer for automatic replacement of PM filter (φ 47 mm) | |||||

| Valve switching | Additional air valve before filter (Replacement of sampling filter on bypass mode) | |||||

| HOST interface*3 | LAN communication using a 10 Base T port Conforms to IEEE802.3 (ISO880 2/3) | |||||

| Conditioner for dilution air / Compressor | ||||||

*1, For the filter face velocity in the regulations (less than 100 cm/s), the flow rate for the φ47 mm filter must be 65 standard L/min.

*2, Input the amount of PM collected on filter to calculate PM mass. It is necessary to input engine output (kW) to calculate the PM mass engine output (g/kWh).

*3, Please contact HORIBA, when you order.