Semiconductor Process Application

CMP (Chemical Mechanical Planarization) Slurry composition characterization.

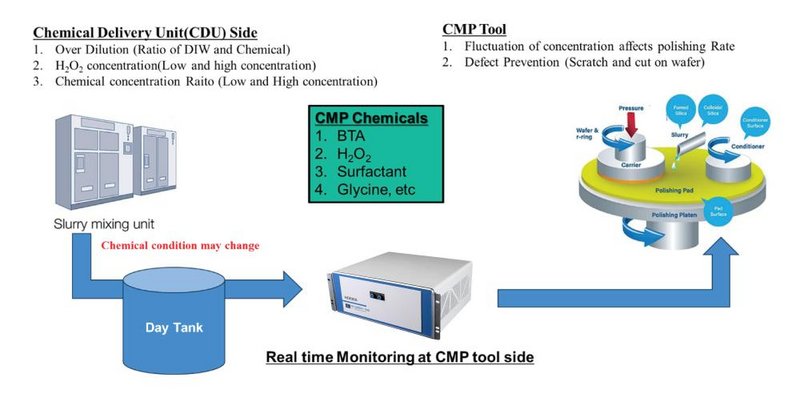

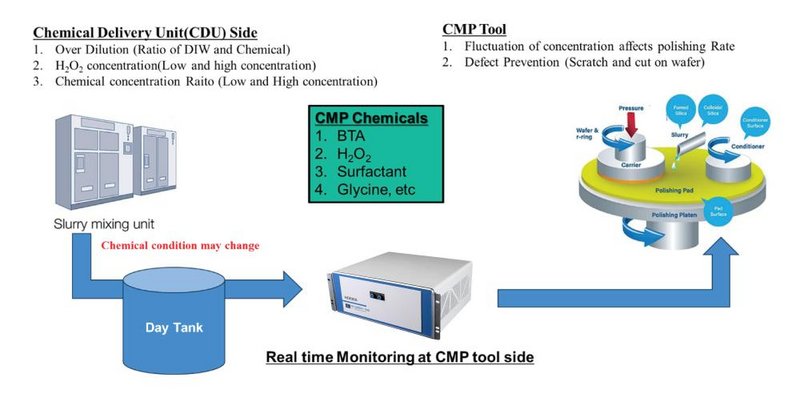

CMP slurries are precisely formulated aqueous suspensions of abrasive materials with added chemicals such as hydrogen peroxide, surfactant and corrosion inhibitors. In production line, concentration fluctuation of these chemicals affects the polishing rate as well as the occurrence of defects (e.g., scratches on wafer) during the CMP process.

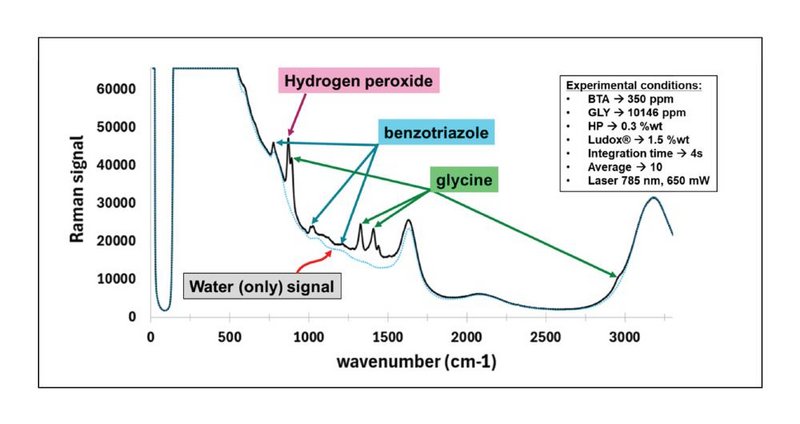

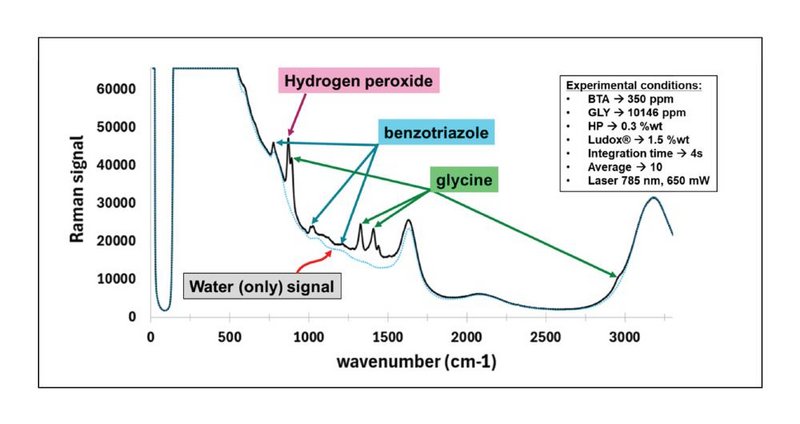

The ProRAM-785 uses Raman spectroscopy, a light scattering technique that returns information related to chemical structure, phase, crystallinity and molecular interactions.

Advantages of using Raman technology for CMP slurry monitoring:

- This is a non-destructive technique to measure the concentration of chemicals without any dilution.

- Multiple chemical species can be monitored at the same time.

- Quick measurement time (a few seconds to minutes).

- This technique can realize real time monitoring of CMP Slurry composition thus enabling preventive measure.

- Existence of abrasive particles such as Alumina, Silica and Ceria minimally affect Raman measurement.

- Oxidizing agents such as Hydrogen peroxide (H2O2) can be characterized by Raman technique.

ProRAM-785 provides an excitation laser at 785 nm, having a flow cell for CMP slurry to flow through it during a Raman measurement. The point of use (POU) can be done at a chemical blending bath and CMP polishing tool to monitor and prevent possible occurrence of defects.

Image of Data Outputs