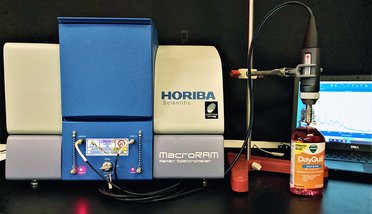

Production and Manufacturing engineering are linked together in the creation of a new product. HORIBA Ultima Expert solution focuses on the minor and major elements and metals analysis. These applications are common to mining, chemicals manufacture, salt production, wear metals in oil analysis, petrochemical and metallurgical production.

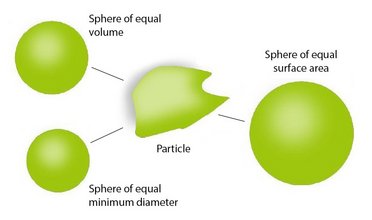

While the particle size analyser contributes significantly to manufacturing science, technology development providing readings from below 1 nanometer to 30 millimetres. Enabling your research to be cost efficient, knowledge intensive, high value and environmentally friendly in production. Let HORIBA assist you with your research lifecycle.

This webinar is focused on the use of HORIBA's high-resolutive ICP-OES technique to ensure the determination of major and minor elements in cements.

Find Out More

Do you have any questions or requests? Use this form to contact our specialists.