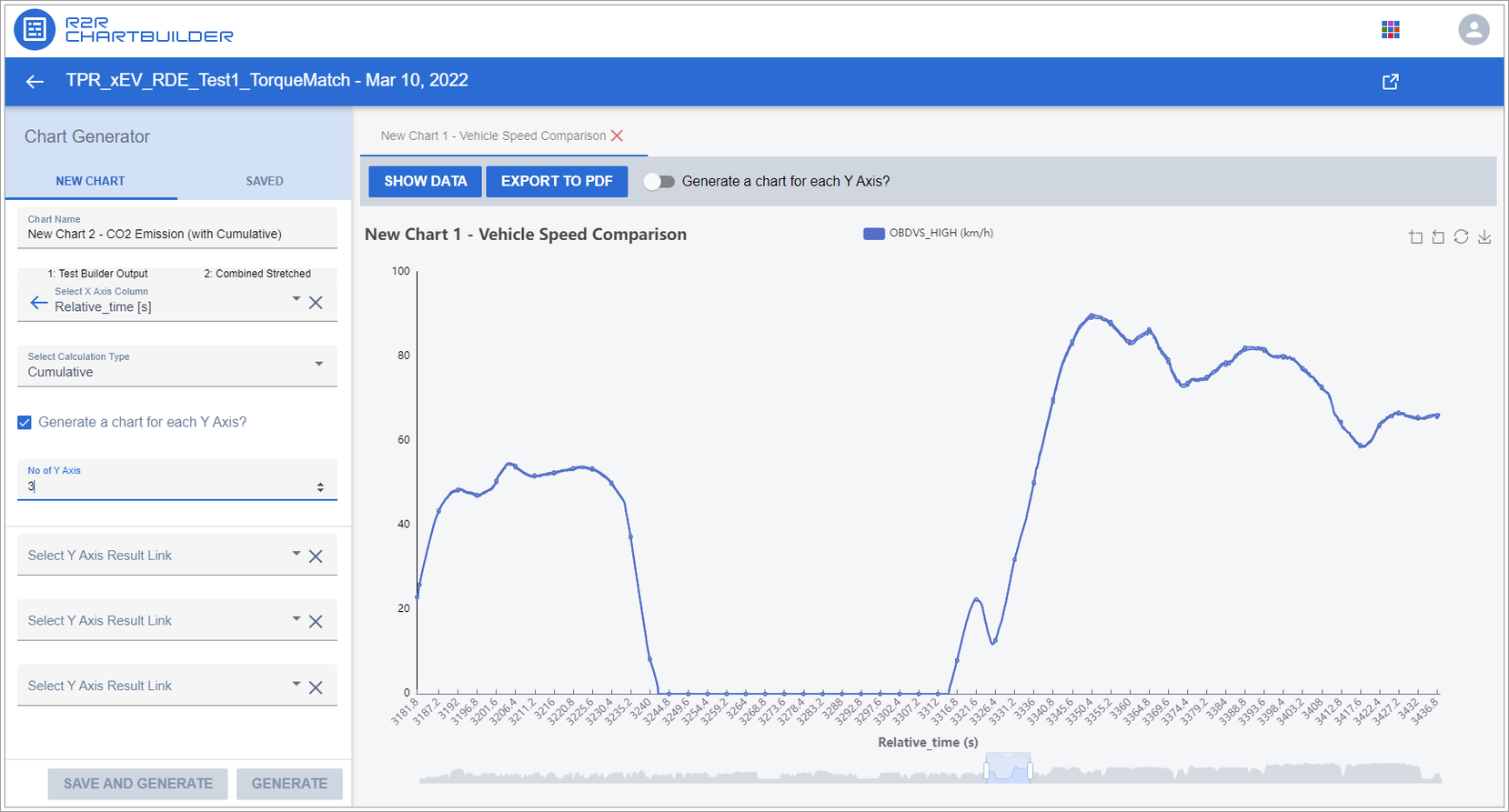

The approach doesn’t require coast down, road gradient, wind tunnel, tire resistance, or direct axle torque measurements because it relies on stimulating the vehicle in exactly the same way as during the original test drive.

A chassis dynamometer is set to achieve the exact road speed recorded during the test drive and the inputs - throttle, brake and gear changes - are perfectly replayed. As far as the vehicle’s control systems are concerned the same inputs are being given to it and the same external resistances (dyno torque) is being experienced. The result is a near perfect replication of the emissions, electrical energy use and performance when compared to the road test.

The traditional method, road load simulation (RLS), is used across the industry. However, the method makes several assumptions and uses measured data to create a road load model for a dynamometer. These assumptions and measurement tolerances mean that RLS replication is not as accurate as it could be. Torque matching gets around this problem.

Features of Torque Matching

- Replicate a road test in the lab from minimal road test measurement data.

- Replicate real-world scenarios repeatably and robustly

- High accuracy replication of vehicle inputs leads to a high correlation of outputs

- Benchmark vehicles of similar size with the same replication torque

- Emulate the original road test with different environmental conditions (temperature, humidity, pressure) and calibrations or components and see the effect on the outputs.

Benefits of Torque Matching

- Reduce the need for pre-test measurements to derive RLS coefficients (coastdown, rolling resistance tire testing, wind tunnel testing, road grade profiling etc.)

- Reduce the requirement for real-world environmental testing

- Fewer altitude or road-based tests are needed

- Benchmark and correlate test labs with a golden vehicle accurately

- Environmental effects can be explored quickly and repeatably

- Check failure modes found in the fleet and evaluate corrective actions

- Use existing hardware and automation systems from HORIBA and 3rd parties.

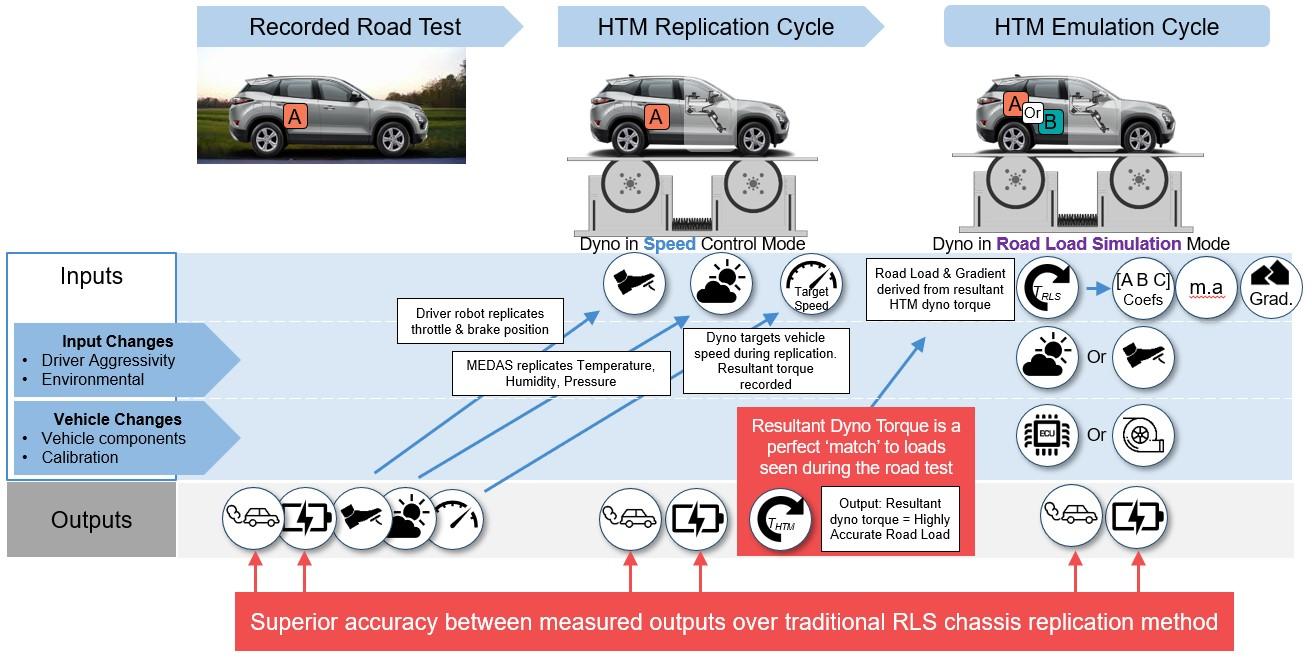

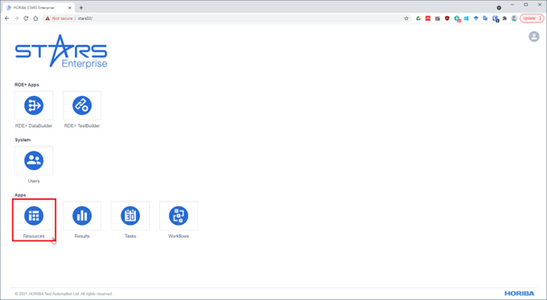

HORIBA Automotive R2R Torque Matching Application Software

Our Data Builder, Test Builder, and Chart Builder software enable torque matching replication and emulation capabilities. They are available as software applications that run within the STARS Enterprise environment either in the cloud or on a local computer.

The use of the software applications and the overall process of replication and emulation can be embedded into a STARS Enterprise workflow to give you a secure and repeatable process that can be integrated within the overall lab management and data control system.

- Seamless test data capture

- Data transformation into test procedures

- Results recording and playback

Torque Matching Applications are Available on STARS Enterprise

The apps have been developed with flexibility in mind.

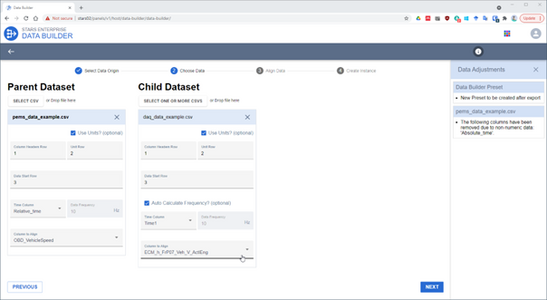

R2R Data Builder

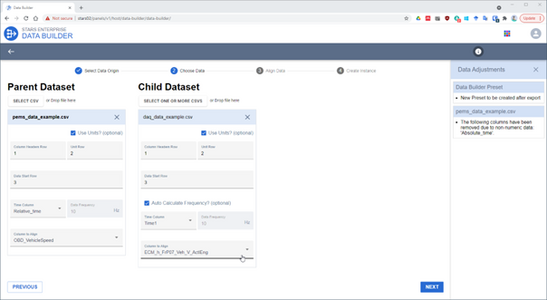

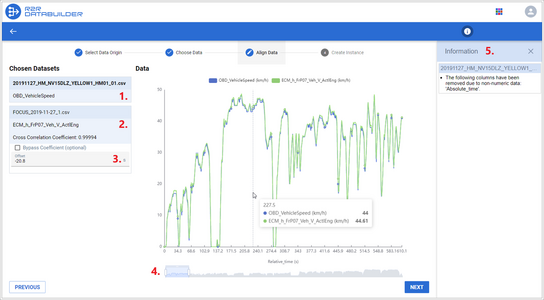

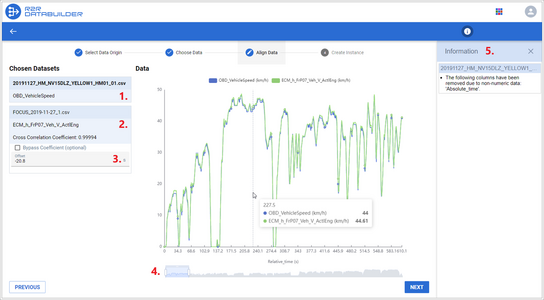

Data Builder takes the recorded road test data from either a PEMS or another data logger and transforms the data so that it can be used as an input to a dynamometer automation system such as STARS VETS.

Simply upload test drive data to Data Builder via the Enterprise web interface, then manipulate the dataset to get it time aligned. Next, download the mapped channels or a CSV file to feed into the automation system.

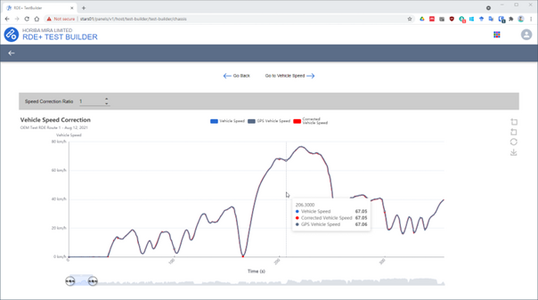

R2R Test Builder

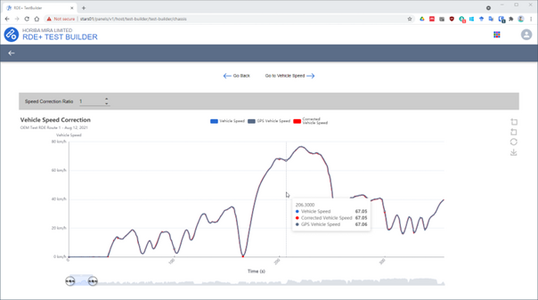

Test Builder processes the information from Data Builder and creates a definition of the road test in a formatted data file for the dynamometer test automation system. The automated system can then control the dyno, driver robot, and climatic systems to perfectly replicate the road test in the lab.

The software is initially configured for VETS 2.x and STARS EV, but it can be reconfigured to deliver files in formats suitable for other common test automation systems.

Test Builder processes the road data to automatically determine and define transmission changes which it uses to control robot interventions. All instrumented pedals and selectors can be processed for control during the lab-based replication test.

Test Builder with torque matching is offered in two levels:

- Replication only for customers who only require replication of road tests (such as regulatory bodies, EPA, CARB, VCA, etc.)

- Replication and emulation for customers who require the capability to evaluate system changes over the measured road-test in the lab (such as OEMs and Tier 1s).

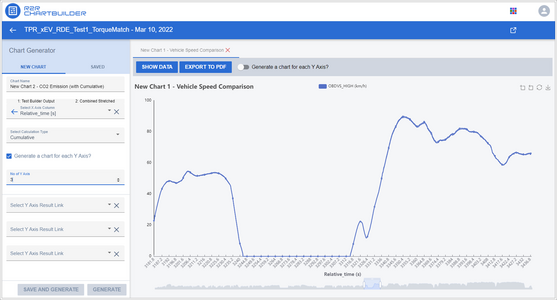

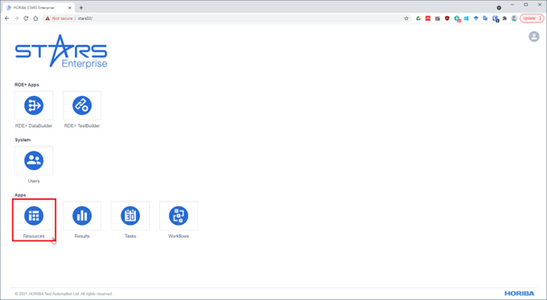

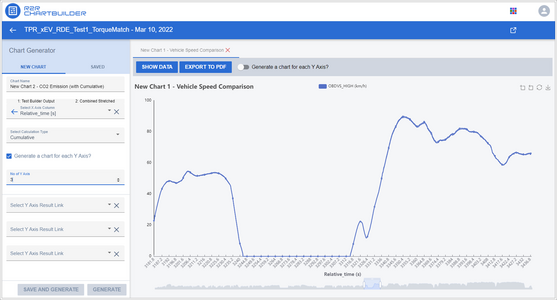

R2R Chart Builder

- Chart Builder quickly and easily generates configurable charts from the replication and emulation test results.

- It allows engineers to study the data and approval or reject the test. It can also highlight areas for further investigation.

- The solution also removes the need to transfer data to another charting software, enhancing the effectiveness of your workflow.