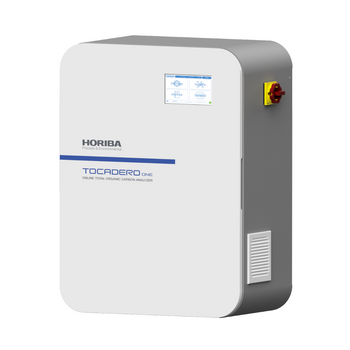

Use of the TOC meter in a regulated environment

The Tocadero EVO TOC meter is specially designed for use in regulated industries such as the pharmaceutical industry. It helps you comply with international requirements, including 21 CFR Part 11, with a compliant software solution featuring audit trail, log, and tracking functions. This ensures traceable data integrity and compliance with the requirements of common pharmacopoeias such as USP and Ph. Eur. Thanks to its reliable differential conductivity measurement, the device is ideal for monitoring PW, HPW, and WFI in GMP-regulated processes.

What makes this TOC meter unique

- Results in seconds: Continuous online measurement for immediate TOC values.

- Reagent-free: No chemicals required – safe, sustainable, and cost-effective.

- 21 CFR Part 11 ready: Ideal for regulated industries such as pharmaceuticals – including audit trail and data security.

- Dual mode: Online monitoring plus offline measurements with optional autosampler.

- Long-lasting UV technology: Maximum measurement accuracy with minimal maintenance.

- Automatic dilution: Lower consumption, precise calibration, easy operation.

- Compact & low maintenance: Saves space, time, and resources during operation.

Easy calibration with integrated sample pump and dilution

No additional equipment is required to calibrate the Tocadero EVO. The integrated sample pump automatically feeds the calibration standard into the device. The different concentration levels are produced and measured autonomously using the dilution function. This saves time and money on additional equipment or standards and gives complete flexibility in terms of when and how the Tocadero EVO is calibrated.

High comparability of laboratory and online measurements

Individual samples often have to be taken during the course of the process and measured in the laboratory. The comparability between laboratory and online measurements is often questionable. However, if the same system is used for online and laboratory measurements, comparability is guaranteed 100%.

Applications

| Industry | Application example |

|---|

| Pharmaceuticals, medical technology & biotechnology | TOC monitoring in WFI production systems, TOC control in cleaning validation, TOC measurement in cooling water circuits, and TOC monitoring in pharmaceutical wastewater. |

| Semiconductor & Electronics manufacturing | TOC monitoring in ultrapure water systems, TOC control in process chemicals, TOC measurement in CMP slurries, and TOC monitoring in semiconductor wastewater. |

| Seawater desalination | TOC measurement in seawater inflow, TOC control in membrane cleaning solutions, and TOC monitoring in concentrate effluent. |

| Hydrogen production | TOC control in electrolysis water, TOC monitoring in cooling circuits, TOC measurement in electrolyte solutions, and TOC monitoring in process wastewater. |

| Energy generation/ Power plants | TOC monitoring in boiler feed water, TOC control in cooling water systems, TOC measurement in condensates, and TOC monitoring in power plant wastewater. |

| Drinking water treatment | TOC measurement in raw water, TOC monitoring after treatment stages, TOC control in pure water, and TOC monitoring in municipal wastewater. |

| Cosmetics & Personal Care Industry | TOC control in production water, TOC monitoring in cooling systems, TOC measurement in process solutions, and TOC monitoring in cosmetic wastewater. |

| Chemical industry | TOC monitoring in reactor cooling water, TOC control in process water, TOC measurement in catalyst suspensions, and TOC monitoring in chemical wastewater. |

Service and Support

When service is required, you will be assisted by a qualified contact person – not a call center. If necessary, a technician will be on site within 48 hours. All maintenance information is provided clearly, comprehensively, and directly by the system – for maximum transparency and minimal downtime.

Made in Germany – Economical, Sustainable, Durable

The Tocadero EVO is manufactured in Berlin. For you, this means short delivery routes, fair prices, and long-term supply security. Consumables and replacement materials are inexpensive, and maintenance costs are low—a well-designed solution for cost-conscious operators.