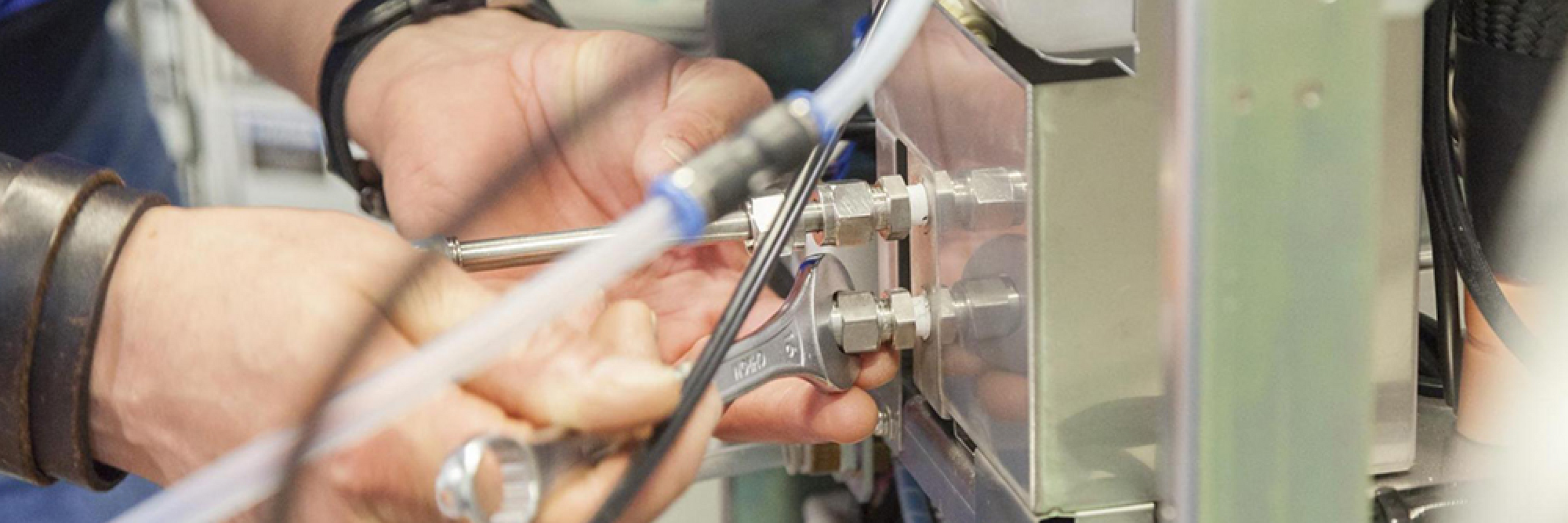

Regular, proactive maintenance is essential to ensure the longevity and performance of your testing systems. By identifying potential issues early and maintaining your equipment at factory standards, you can avoid costly unplanned downtime, safeguard test quality, and extend equipment life.

Automotive Testing Maintenance Services

HORIBA offers customized preventative maintenance programs designed by experienced equipment specialists. Each plan is tailored to the specific needs of your test facility and developed to optimize equipment performance while keeping your schedules on track.

Our programs can include both hardware and software maintenance, ensuring that every aspect of your system functions according to the latest specifications and standards. Maintenance activities can also be aligned with applicable global regulations, such as WLTP, CFR, or other customer-defined criteria.

All maintenance services are performed by HORIBA Service Engineers—a team of highly trained specialists who work according to strict factory quality standards. They are continuously trained, stay current with changing industry regulations, and use specialized verification tools and factory-certified procedures.

Thanks to continuous factory support, you benefit from consistent service quality worldwide—whether work is carried out at your site or at one of our dedicated HORIBA facilities.

Implementing a scheduled maintenance plan provides measurable operational and financial advantages:

A preventative maintenance contract provides peace of mind and operational security. Customers benefit from a defined Service Level Agreement (SLA) covering spare parts, repairs, and guaranteed service response times. Both parts and labor are included and fully guaranteed under HORIBA’s maintenance framework.

FQ series fuel flow meter

e.g. FQ series; DP sensors and other fuel flow meters

To mitigate sensor wear and maintain accuracy, regular overhauls are essential. We offer tailored services to keep your sensitive measurement devices in top condition.

Your advantages:

Our services:

We specialize in type-independent overhauling and repair of asynchronous motors, including HORIBA models such as DYNAS3, VULCAN, and GIANT, but also older models from Schenck.Our services help prevent unexpected failures and ensure continued operational performance.

Your Advantages:

Our Services:

Despite their durability, both hydraulic dynamometers and eddy current brakes require regular maintenance to ensure long-term performance. We recommend scheduled overhauls by the manufacturer.

Your advantages:

Our services:

Types: LSR, LFE 2003/-2, and related actuators

Preventive maintenance helps avoid operational failures and reduce costs. We provide tailored service for actuators and servomotors at our premises.

Your advantages:

Our services:

As the original equipment manufacturer (OEM), HORIBA provides full-service capabilities, from on-site maintenance to complete overhauls and repairs at our service centers. Our goal is to ensure your test benches and measuring systems continue operating at peak performance, day after day.

For more information or to discuss your specific maintenance needs, please contact us using the form below.

Você tem alguma dúvida ou solicitação? Utilize este formulário para entrar em contato com nossos especialistas.