Preventing accidents caused by gas leakage is a significant challenge in various production facilities and plants, such as steel manufacturing mills, chemical, petrochemical and other types of facilities. This challenge arises due to the aging of facilities and a decrease in experienced personnel capable of providing safety guidance.

It is of utmost importance to proactively prevent accidents for the well-being and safety of workers, safety of the surrounding environment and residents, and the stable operations of the plant.

▷ One analyzer for monitoring multiple sampling points over a wide area

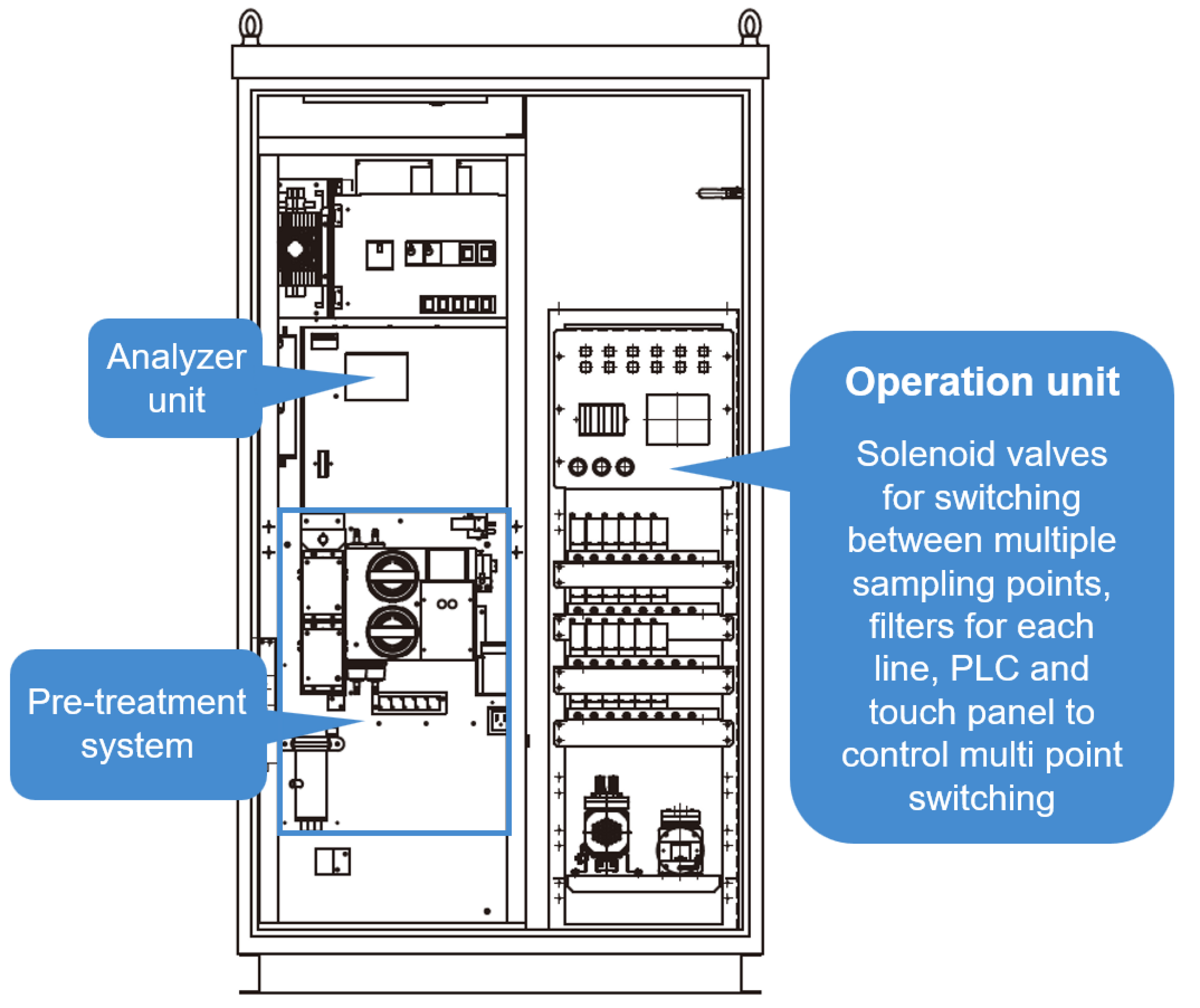

The switching of multiple sampling points enables the measurement of a wide area with a single analyzer.

▷ Excellent maintainability

Compared to installing many simple sensors, our solution involves only one analyzer. This allows maintenance in a single location, contributing to a reduction of maintenance cost and increased work efficiency.

The analyzer equipped with automatic calibration function that facilitates daily maintenance.

▷ Accurate measurement of gas components across wide range, even at low concentrations

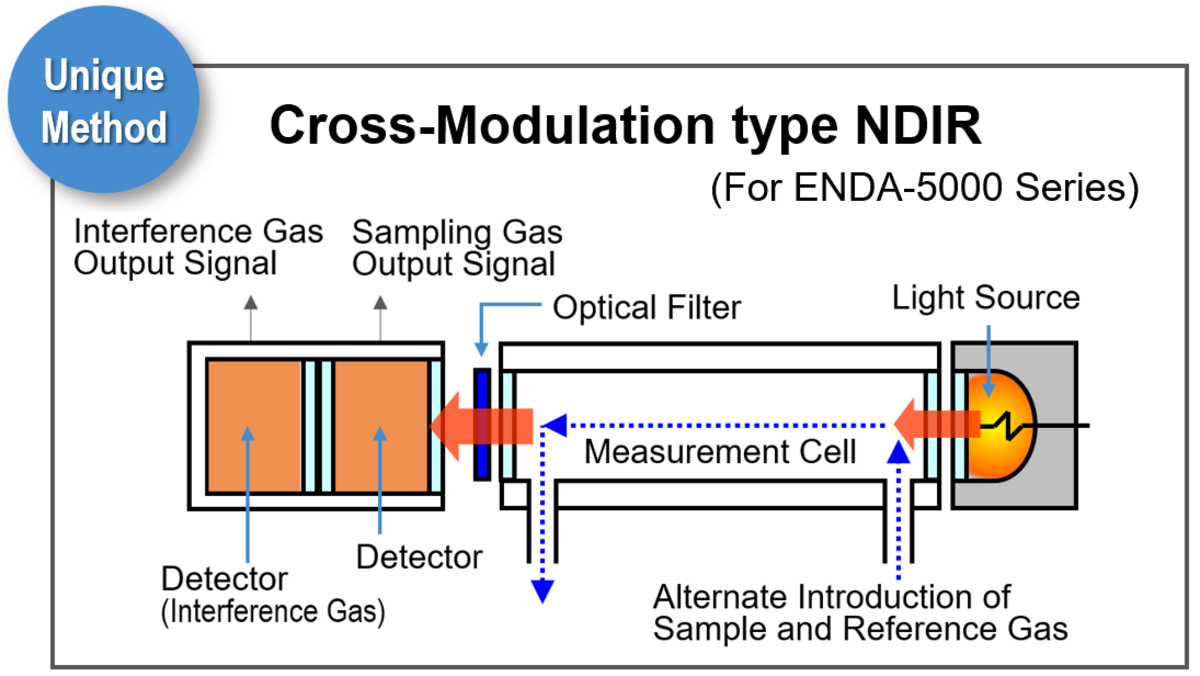

Due to HORIBA's original Cross-Modulation NDIR technology (refer to Fig. 2) adopted to the ENDA-5000 analyzer, it is capable of performing stable and accurate measurements and detecting concentration changes even at low parts per million levels.

Figure 1: Gas leakage detection for accident prevention

Figure 2: Detector design of Cross-Modulation NDIR

We propose the appropriate equipment depending on the site environment, measurement components, and other circumstances.

Stack Gas Analyzer ENDA-5000 Series

Analyzers with excellent long-term stability

Multi-Component Gas Analyzer VA-5000 Series

Capable of simultaneous measurement of 3 sampling points by 1 unit

Explosion-proof Gas Analyzer 51 Series

Explosion proof design for application at petrochemical plant etc.

*Per- and Polyfluoroalkyl Substances

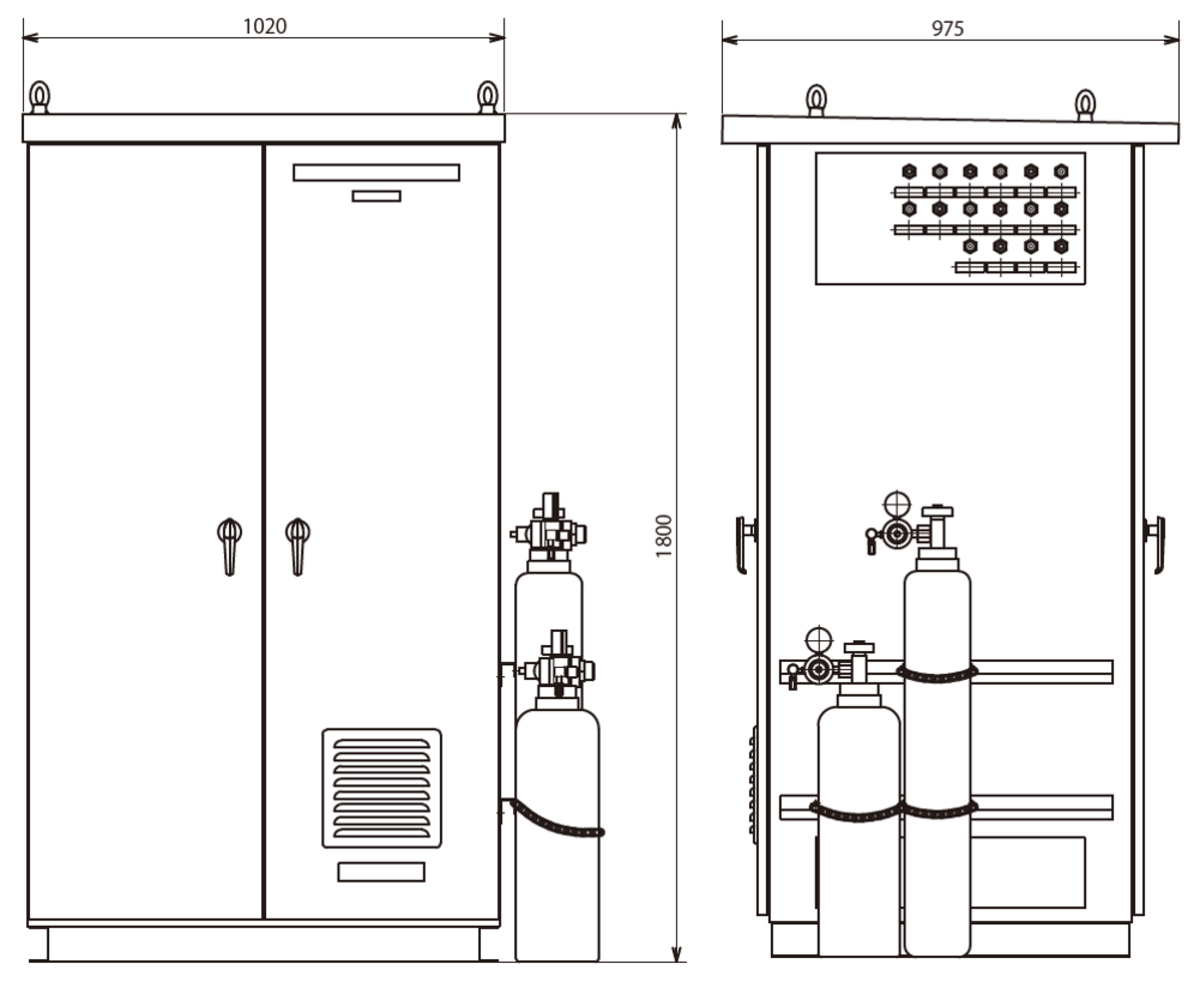

Figure 3. Analyzer for gas leakage detection

Gas component | Min. measurement range | Zero drift / Span drift | Repeatability |

| Carbon Monoxide(CO) | 0-200 ppm | FS±2%/week | FS±0.5% |

| Carbon Dioxide(CO2) | 0-100 ppm | FS±2%/week | FS±0.5% |

| Methane(CH4) | 0-200 ppm | FS±2%/week | FS±0.5% |

| Propane(C3H8) | 0-100 ppm | FS±2%/week | FS±1.0% |

| Nitric Oxide(NO) | 0-200 ppm | FS±2%/week | FS±0.5% |

| Sulfur Dioxide(SO2) | 0-200 ppm | FS±2%/week | FS±0.5% |

Per- and Polyfluoroalkyl Substances (PFAS) | 0-10 ppm | FS±4%/day | FS±1.0% |

Please contact us for PFAS and other types of gas not listed in the table above. For propane gas, 51 series of gas analyzer is utilized.

Figure 4. Example of the system with 12 switching sampling points

Figure 5. Example of internal disposition

Multi-Component Gas Analyzer

Stack Gas Analysis System

Explosion-proof Gas Analyzer

Máte nějaké dotazy nebo požadavky? Pomocí tohoto formuláře kontaktujte naše specialisty.