Industrial/ Medical Gases

Specialized analyzers and applications for processes in industries such as trace impurity measurement in industrial gases and high purity measurement of medical gases

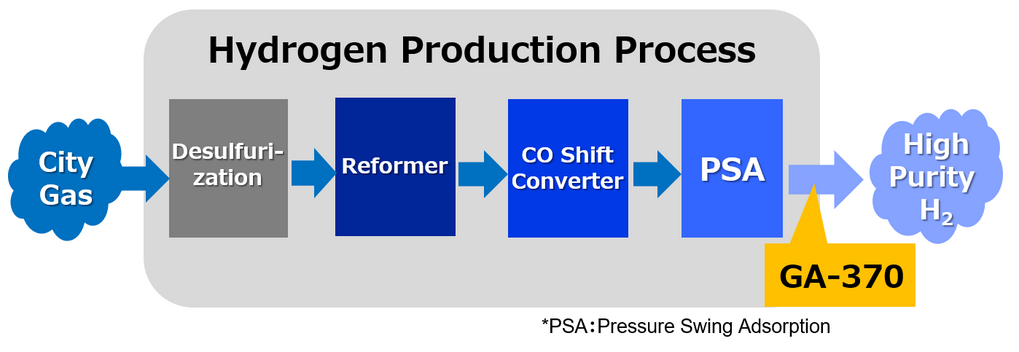

Demand for hydrogen, which has been attracting attention as a clean energy source, is expected to increase for energy applications in the areas of fuel cells and hydrogen gas turbines in addition to conventional industrial applications. ISO 14687-2 defines hydrogen quality standards for fuel cell vehicles, and failing to comply with these standards leads to poisoning of the catalyst and fuel cells.

*PSA: Pressure Swing Adsorption

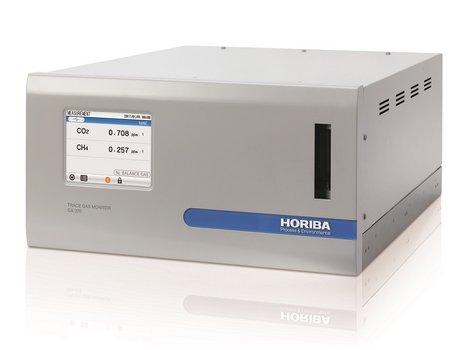

HORIBA's GA-370 trace gas analyzer can continuously measure impurities in hydrogen gases with high sensitivity. It can stably measure substances that are major causes of poisoning, including CO at a minimum detection sensitivity of 10 ppb and with a low range of 0 to 1 ppm.

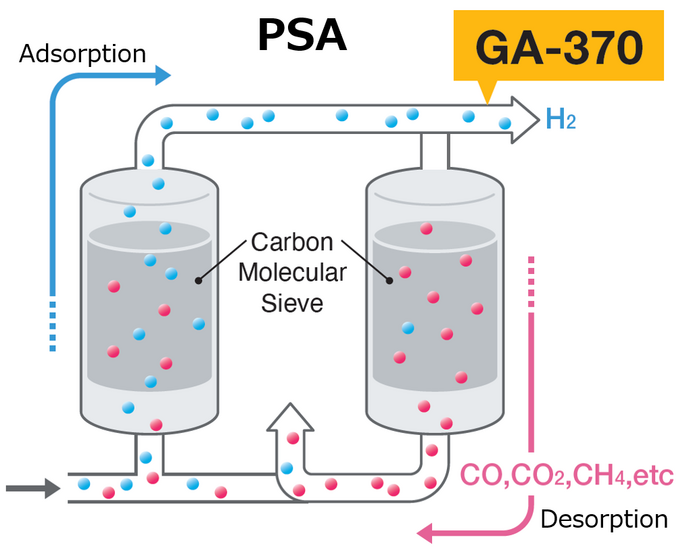

The GA-370 can also measure up to two components, such as CO and CH4, at the same time with a single unit. This will help to know the performance of PSA and timing to exhange the catalyst inside.

Trace Gas Analyzer GA-370 controls the quality of high-purity hydrogen gas, by monitoring the concentration of CO, CO2 and CH4 among the impurities generated in the hydrogen.

In PSA during the manufacturing process, GA-370 monitors the concentration of impurities in real time. It contributes to hydrogen quality control and reduction of manufacturing cost.

Similar to hydrogen production plant, GA-370 monitors the concentration of CO, CO2, CH4 among the impurities generated in the hydrogen production equipment, at on-site hydrogen fueling station. Grasping these concentrations are significant because those would deteriorate the fuel cell of vehicles.

Máte nějaké dotazy nebo požadavky? Pomocí tohoto formuláře kontaktujte naše specialisty.