Electrochemical dissolved oxygen (DO) electrodes are composed of anode and cathode, which are submerged in electrolyte solution and enclosed in a cap fitted with hydrophobic, gas permeable membrane. They are also integrated with temperature sensors to measure the temperature of standards and samples and allow the DO meter to compensate the temperature effect on the measured DO values. There are two types of electrochemical DO electrodes: polarographic and galvanic. The advantages of galvanic DO electrodes over polarographic DO electrodes are that they don’t require outside voltage source and warm-up time to operate and their electrolyte can be used indefinitely.

Electrochemical DO electrodes available in the market have replaceable electrolyte and either loose membranes or membrane cap assemblies (caps pre-fitted with membranes). The usual maintenance involves periodic changing of the membrane or membrane cap assembly, refilling the electrolyte, and cleaning the anode and cathode. To reduce downtime, the replaceable parts should be readily available and users should know how to perform maintenance.

With the advantages of galvanic DO electrodes and improvement of user experience in mind, HORIBA introduced galvanic DO electrodes equipped with replaceable innovative DO tips for hassle-free plug-and-use operation and built-in temperature sensors for temperature compensation on measured DO values. The DO tips require no maintenance, making them beneficial for both expert and novice users and ideal for continuous measurements in the laboratory or field. Simply, plug the DO tip into the electrode body to perform calibration and measurement and unplug it when the DO electrode will be stored for a long period.

Materials Needed

Selection

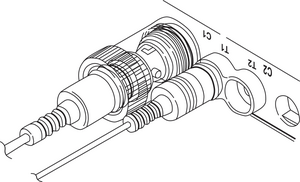

There are two DO electrode models available, the 9520-10D with 7541 DO tip and 9551-20D (1m cable) / 100D (10m cable) with 5401 DO tip, which are intended for laboratory and field applications, respectively. Electrode bodies are made of durable plastic. The DO tips have lead anode and silver cathode submerged in KOH electrolyte solution and isolated from sample by a gas permeable membrane.

Aside from DO tips, the DO electrodes are also supplied with accessories. The 9551-20D comes with stirrer (and its casing) and an adapter to fit the electrode body into standard biological oxygen demand (BOD) bottles. A magnetic stir plate should be used with the DO electrode for the stirrer to function. The 9551-20D / 100D comes with stainless steel protective guard that shields the DO tip from getting damage and attached cable hook that helps secure the electrode’s connection to the meter and prevents the cable from breaking.

Preparation

Each DO electrode comes with one DO tip. The DO tip is packaged with a drying agent in a sealed aluminum foil bag when shipped. It must be plug into the electrode body before using the DO electrode. Refer to the electrode manual for the procedure.

Calibration

One or two calibration points can be performed on the DO meter / electrode system before measuring samples. For most applications, air calibration is sufficient. Calibration should be checked daily and after relevant changes of ambient conditions (i.e. temperature or pressure). If DO is a critical parameter or sample has low DO value, it is recommended to perform a second calibration point or a check using a zero DO solution.

Set the atmospheric pressure (also called air pressure) in the DO meter before calibrating in either saturation ratio (%) mode, also known as percent saturation mode, or DO (mg/L) mode. If measurement will be carried out at sea level, no need to adjust the default setting 101.3 kPa (equal to 1 atm = 760 mmHg). If measurement is at high altitude, measure the atmospheric pressure with a pocket barometer or check it from your local weather service and enter the value into the DO meter. The atmospheric pressure decreases as altitude increases. Refer to the meter manual for the atmospheric pressure setting and calibration procedures in saturation ratio (%) mode and DO (mg/L) mode.

Sample Measurement

When measuring samples, take note of the following:

Cleaning

If the membrane is dirty, wipe it gently with soft cotton gauze or tissue then rinse with clean water. Be careful not to scratch the membrane.

Storage

DO electrodes should be clean before they are stored for any length of time.

Short-term

1. Leave the DO electrode connected to the meter.

2. Immerse the DO tip of 9520-10D in zero DO solution (5% Na2SO3 solution = 50g Na2SO3 in 1L DI water) and the DO tip of 9551-20D / 100D in clean water (e.g., distilled, deionized, or tap water) to prevent the membrane from drying out.

9520-10D

| 9551-20D / 100D

|

Long-term

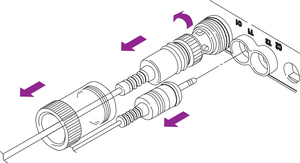

1. Disconnect the DO electrode from the meter.

2. Detach the DO tip from the electrode and plug the short socket into the DO tip.

9520-10D

|

9551-20D / 100D

|

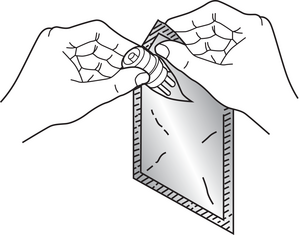

3. Wrap the DO tip with aluminum foil. You may reuse the original packaging, if it is still in good condition. Alternatively, place the DO tip in a bottle containing drying agent and store in a cool, dark place.

23 November 2017, Rev. 0

Do you have any questions or requests? Use this form to contact our specialists.

HORIBA Advanced Techno, Co., Ltd.

31, Miyanonishi-cho, Kisshoin

Minami-ku Kyoto 601-8306 Japan

Tel: +(81) 75 321 7184

Fax: +(81) 75 321 7291

HORIBA Instruments (Singapore) Pte Ltd.

83 Science Park Drive, #02-02A,

The Curie 118258 Singapore

Tel: +65 6 908 9660

Fax: +65 6 745 8155

Mail: laqua(at)horiba.com

HORIBA UK Limited Northampton Office

Kyoto Close,Summerhouse Road,

Moulton Park

Northampton NN3 6FL UK

Tel: +(44) 1604 542 600

Fax: +(44) 1604 542 699

Mail: waterquality(at)horiba.com

HORIBA Instruments Incorporated Head Office

9755 Research Drive

Irvine California 92618 USA

Tel: +1 800 446 7422

Fax: +1 949 468 1790

Mail: labinfo(at)horiba.com

You might also like to know...