Product Specifications

This combined test system offers the possibility to perform the following tests on the test specimen:

- Saltwater Test (spraying the test specimen with saltwater)

- Wet Test (for sprinkling the test specimen with water)

- Fog Test (for fogging the test specimen with water mist)

- Rinse with water

- Flushing with air

This newly developed system is fully integrated into and controlled by the STARS Brake test stand automation system.

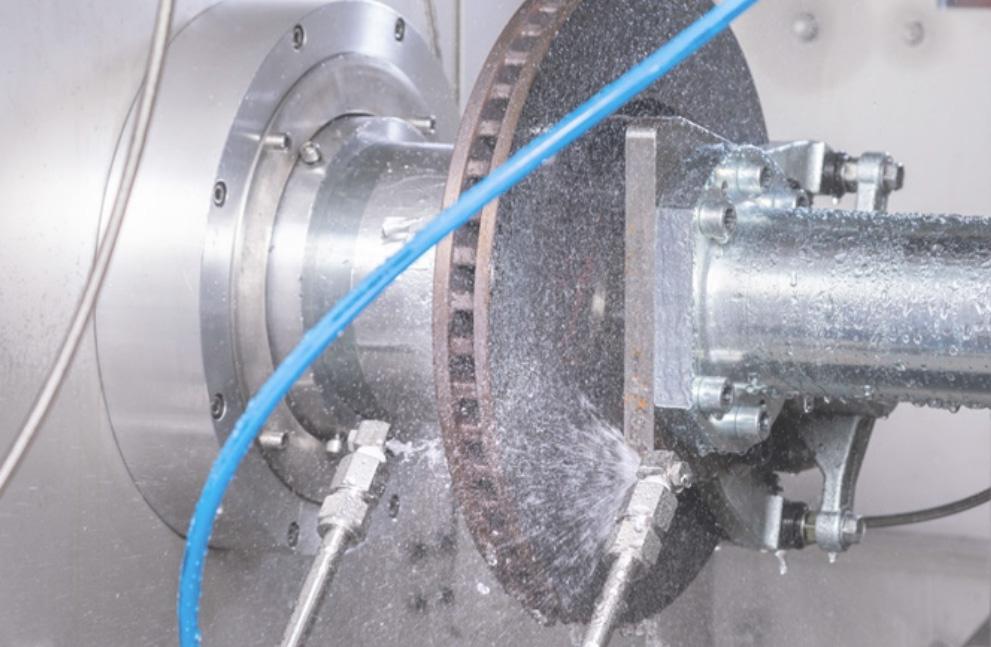

The attached pairs of nozzles together with the pressures of compressed air and water pressure, which can be adjusted by the control system, determine the respective flow rates. With this newly developed system, flow rates for saltwater and water of 1.5-5 liters/min (accuracy ± 5%) can be applied to the test specimen. The flow rates can be controlled in STARS Brake. Special pulsation dampeners built into the system enable pulsation-free spraying of the test specimen with water, saltwater and water mist.

To be able to realize all 3 test types, a special electrical control box is supplied. This is mounted on the side of the dosing cabinet. The system is designed in such a way that all three test types can be run with the same system. The connection points for all necessary media (water / saltwater / compressed air) are also included. The media for the above tests are appropriately combined in the included dosing cabinet by means of electrical valves and are simply passed on to the test specimen via a hose line. A flow sensor is included in the dosing cabinet to measure the total flow rates of the aforementioned media.

Saltwater Test

The salt-water mixture required for the salt-spray test (salt is provided by the customer) is located in a separate 500-liter storage tank. A special motor-driven agitator is mounted on the storage tank to mix the water with salt (activation, deactivation and operation are performed manually via a separate manual control panel). The speed of the agitator can be adjusted manually via a potentiometer on the manual control panel.

A special peristaltic pump is available for conveying the water / saltwater / water mist to the test specimen. This is controlled by a frequency converter. All components of this system are designed for operation with a fully saturated saltwater solution.

Wet Test

To perform the wet test (sprinkling of the test specimen with fresh water), there are electrically controlled valves to switch from saltwater operation to normal water (house connection).

Fog Test

A special multi-substance nozzle pair is included to perform the water mist test. By introducing compressed air, the water is atomized at this pair of nozzles and thus the water mist is generated for the test specimen.

Easy transport and maintenance

The dosing cabinet and the 500-liter storage tank for saltwater are mounted on a separate intermediate platform. The entire system can be easily transported via existing transport lugs.

All connections between the dosing cabinet and the saltwater tank (piping / wiring) are designed to be separable. If the storage tank needs to be separated from the dosing cabinet, these connections can be easily and quickly disconnected.

Cleaning

After using the salt spray test, the piping system must be cleaned to protect it from damage due to the effects of salt. For this purpose, the lines of the system are flushed with the included "Flush with water" function. The wastewater (normal water / saltwater) enters the exhaust air duct of the test stand and must be discharged from this duct by the customer. Any necessary measures for collecting and disposing of the wastewater, saltwater or "rinsing water" must be implemented by the customer.

Following the purging process, the line system must be dried by means of compressed air using the included "purging with air" function. The pneumatic line pressure required for this is automatically specified and controlled via STARS Brake.

If the intention is to carry out climatic tests immediately after the salt spray test, the piping system must first be rinsed with water and then dried with air (as described above) in order to avoid damage to the system due to the effects of cold.

Safety Features

A spring-loaded diaphragm is installed in the dosing line immediately upstream of the nozzles, which prevents any "run-on" after the peristaltic pump is switched off at the test nozzles.

To protect the individual system components mounted on the mounting plate from damage, it is enclosed in a cabinet (the so-called dosing cabinet) included in the scope of delivery. A leakage sensor is installed inside the cabinet. If the sensor is triggered, the system is automatically switched off and a corresponding message is output via STARS Brake.

In addition, a special 500-liter collection tray is provided under the intermediate platform. This tray is designed in such a way that the entire 500L of the storage tank for saltwater can be collected by the collection tray if necessary. This is mandatory for CE conformity. The collection tray is also equipped with a leakage sensor. If this sensor is triggered, it shuts the entire system down and a corresponding message is issued via STARS Brake. If necessary, the collection tray can simply be pulled out from under the intermediate platform (manually / lift truck / forklift).

The filling process of the tank with fresh water, must be activated manually by the operator by pressing a button on the electric cabinet of the system. The filling process of the supply tank is automatically switched off as soon as the level sensor for the maximum filling level is activated. In the unlikely event that this sensor for switching off the filling process should fail, a "backup switch-off sensor" for the filling process is installed.

To prevent damage to the system due to "overpressure", the system is equipped with a so-called "bypass line". This is connected directly to the outgoing delivery line of the pump. If the pressure in this delivery line (between the pump and the test nozzles) is too high for the system, this bypass line is opened via a corresponding pressure valve. The medium is pumped back into the reservoir. The entire system is switched off by an additional sensor installed in the bypass line. STARS Brake issues a corresponding message.

Full Integration into STARS Brake Software

A special radar sensor is installed to detect the level in the reservoir. This is also integrated in STARS Brake and continuously and steplessly detects the fill level in the container. When a fill level of approx. 1 cm in front of the tank bottom is reached, the system is automatically switched off. STARS Brake issues corresponding messages for this. Corresponding warning levels (e.g., before the minimum fill level is reached) are also defined in advance together with the customer.

The control of the saltwater - wet and fog test is fully automated via the test program in the STARS Brake Software.