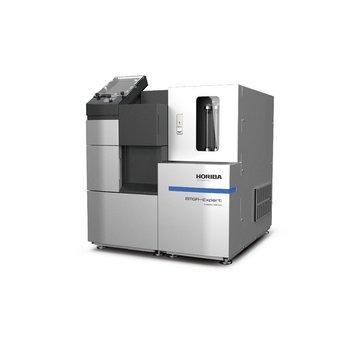

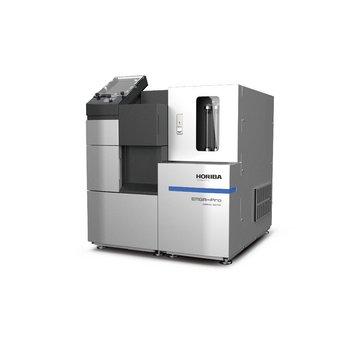

EMGA-921: Hydrogen analyzer

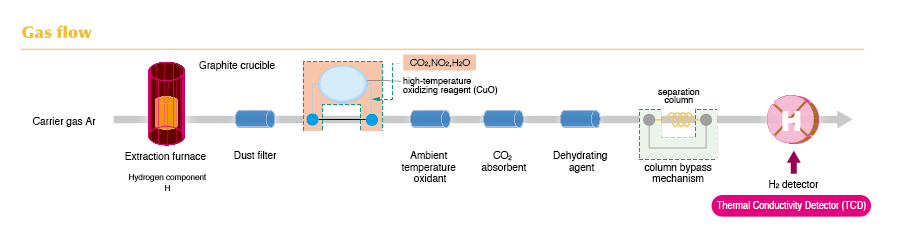

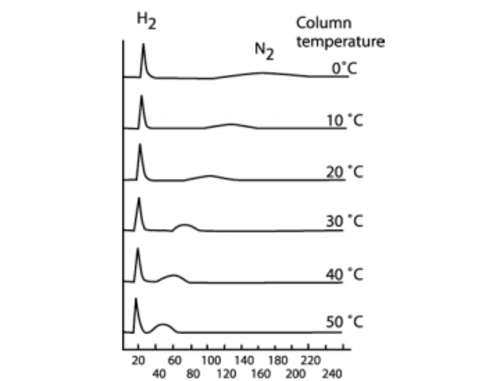

Principle

Hydrogen: Thermal Conductivity detector (TCD)as H2

Measurement range*:

Hydrogen: 0-0.02%

*Possible to increase the range by reducing the sample weight.

Sample weight: 1.0 ± 0.1g

Sensitivity (Minimum reading): Hydrogen: 0.001 ppm.

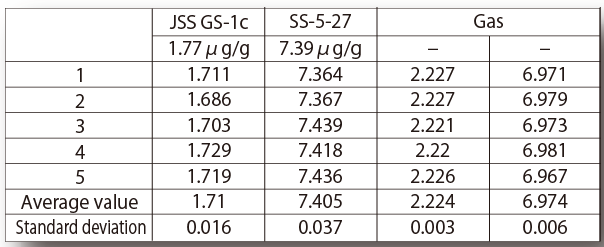

Accuracy** (Repeatability)

Hydrogen

σn-1≦0.04 ppm or RSD≦0.5% whichever is larger (Reference gas)

** Based on the sample weight 1.0 ± 0.1g and with automation functions described below

Display

- Measurement result: LCD or printout

- Alarm message: LCD or printout

- Flow sheet: LCD

Power of furnace

Inert gas fusion in impulse furnace

Enable to set the generating power 0 – 8.0 kw

Sample introduction: Dual sample/flux introduction mechanism

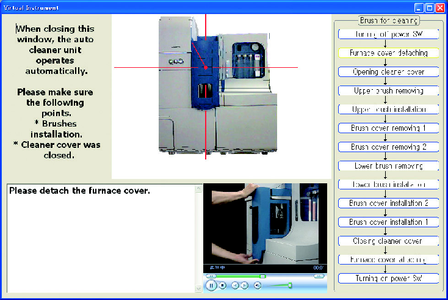

Automation functions: Auto cleaner, Crucible loader

Integration conditions:

Preset time integration

Integration up to reach comparator level

Preset time integration or integration up to reach comparator level, whichever is shorter

Sample ID: Enter up to 20 one-byte characters

Calibration

- One point or multi point calibration (Reference gas or standard samples)

- Calibration using previous analysis data

- Calibration curve correction function

Functions

- Display of real time extraction curve

- Analysis interruption

- Self diagnosis and alarm display

- Analysis of extraction curve (Superposition, difference etc analysis)

- Out put (RC-232C or TCP/IP)

Dimensions: 750mm(H)×785mm(D)×653mm(W)

Sample introduction is positioned at 650mm from table.

Weight: 230kg

On carrying, it is divided in two units (Under 140kg/unit)

Computer: PC model operating OS Windows® XP(SP2) and beyond

Power

Main unit: AC200/220/230/240V ± 10%

Auto cleaner: AC100V (Step-down transformer)

Frequency: 50/60 ± 1Hz

Electric power consumption

Main unit: 12kVA (MAX)

Auto cleaner: 1.5kVA (MAX)

Ground resistance: Less than 10Ω

Installation condition

Operation temperature: 5-40°C

Performance temperature: 5-35°C

Humidity: Maximal relative humidity 80%RH between 5-31℃, linearly decrease down to 50%RH between 31-40℃

Vibration: Duplex amplitude 20micron and less than 0.098m/S2 accelerations at frequency band

Required gas

Ar carrier gas: Purity greater than 99.995%, Pressure 0.35MPa

Stainless steel pipe(O.D.3mm) and suitable connecter fitting within 3m of unit

Dry air or N2 as operating gas: Pressure 0.45MPa

Nylon pipe (O.D.6mm) and suitable connecter fitting within 5m of unit

Cooling mechanism: Radiator unit (Separation type)

Electronic balance (Option)

Enable connection with electronic balance with 1-0.01mg minimum display

Optional automatic voltage regulator (AVR)

Capacity:15kVA

Weight: 130kg