Biomass Power Generation

Normal power generation process solutions + dedicated analyzers and applications for waste power generation

In case of Japan, according to the soot and smoke emissions regulations of the Ministry of the Environment, operators must grasp and record the status of the emissions to the atmosphere as a result of carrying out business activities, and they must take measures necessary to reduce such emissions.

Soot and smoke emitted from a metal refining facility,* one soot-and-smoke-generating facility subject to regulation, contain toxic substances such as heavy metals originated from raw materials. To take effective measures, it is necessary to look into the relationship between the emitted toxic substances and the factory equipment's operating status.

* A facility with emissions over a certain level

Sampling

Sampling

![]()

Sample Preparation

Sample Preparation

![]()

Analysis

Analysis

Simultaneous and continuous measurement of PM2.5 mass concentration and elemental component analysis

Continuous Particulate Monitor with X ray Fluorescence “PX-375”

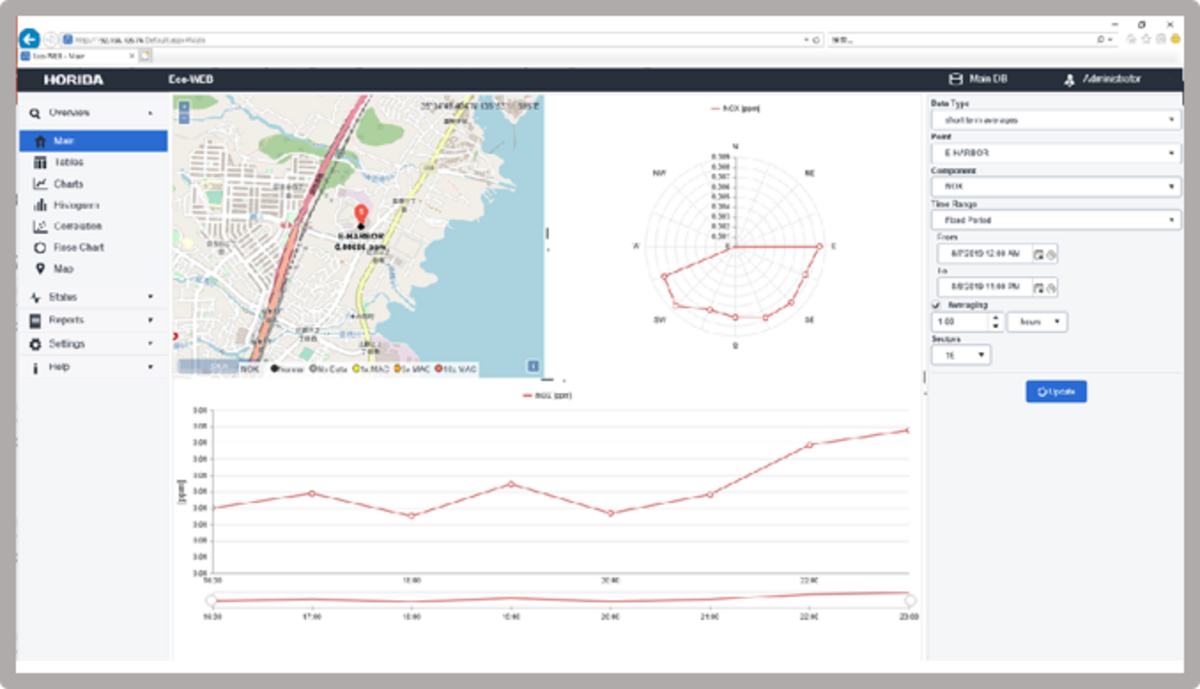

Data Management System “Eco-WEB”

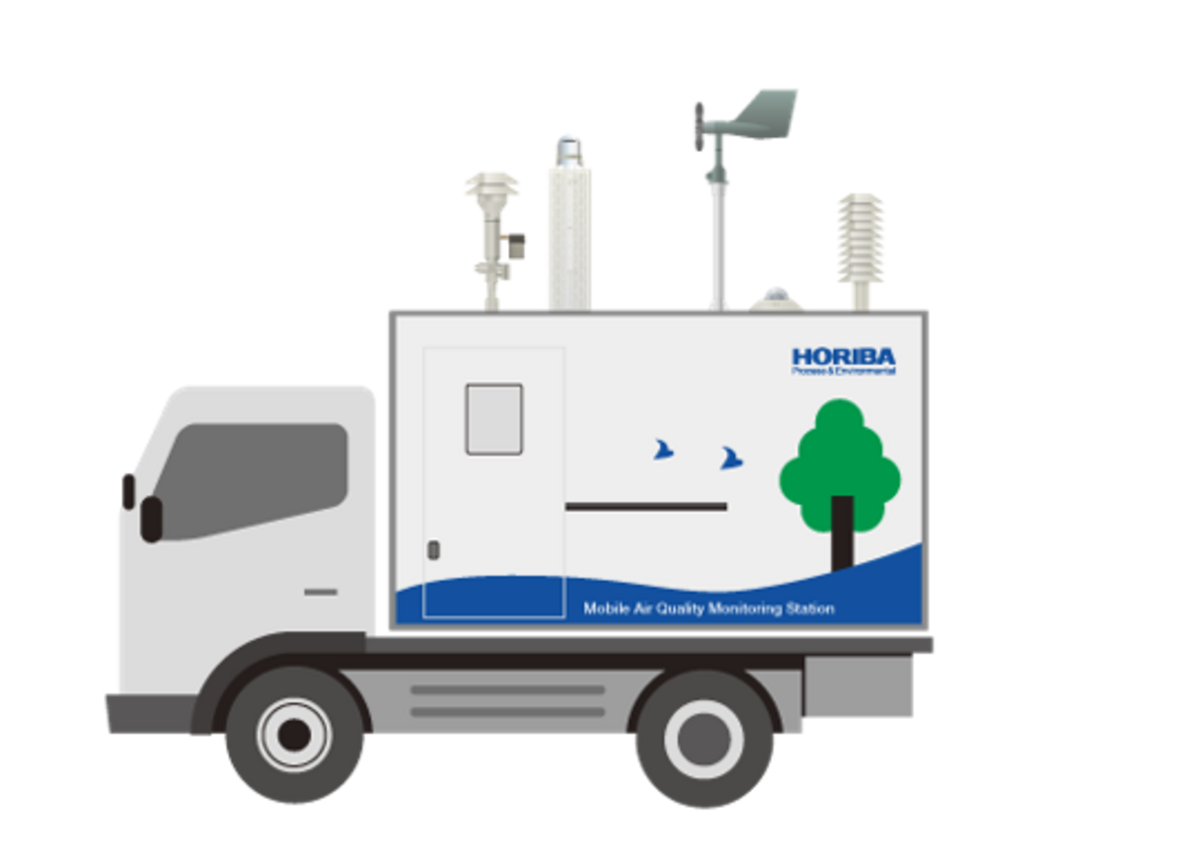

In addition to use at Air Quality Monitoring Stations (AQMS), the PX-375 can be used at Mobile Air Quality Monitoring Station. This can be done thanks to the low power consumption and small size of PX-375. This will help customers who want to measure the multiple points around the facility.

Air Quality Monitoring Station* (AQMS)

Mobile Monitoring Station

* An air pollution continuous monitoring station is a facility in which an automatic measurement system that can continuously monitor climate data, including wind direction and velocity, as well as the concentrations of sulfur dioxide, particulate matter, nitrogen oxide, carbon monoxide, ozone, and others in the air throughout the year is installed.

Continuous Particulate Monitor with X-ray Fluorescence

Air Pollution Monitor

Do you have any questions or requests? Use this form to contact our specialists.