| Model | EIA-51d | EIA-51p | TIA-51d | TIA-51p | ||

|---|---|---|---|---|---|---|

| Type of protection | Exd Ⅱ B+H2T4 | Expx Ⅱ T4X | Exd Ⅱ B+H2T4 | Expx Ⅱ T4X | ||

| Frameproof enclosures | ● | ● | ||||

| Pressurized apparatus | ● | ● | ||||

| Measuring principle | Non-Dispersive Infrared Absorption Method (NDIR) | |||||

| Component | CO, CO2, CH4, etc.*1 | |||||

| Measurement range | Minimum range | 0 to 0.11 vol% (Depends on the component) | 0 to 50 ppm (Depends on the component) | |||

| Maximal range | 0 to 100 vol% (Depends on the component) | 0 to 2000 ppm (Depends on the component) | ||||

| Optional | 100-90 to 50 vol% (Depends on the component) | 0-20 to within less than 50 ppm (Depends on the component) | — | |||

| Range Ratio | — | — | ||||

| Performance | Repeatability | Standard range | Zero : ±0.5% of full scale | Zero : ±0.5% of full scale | ||

| Span : ±0.5% of full scale | Span : ±0.5% of full scale | |||||

| Optional range | Zero : ±0.5% of full scale | Zero : ±1.0% of full scale | ||||

| Span : ±0.5% of full scale | Span : ±1.0% of full scale | |||||

| Linearity | ±1.0% of full scale | |||||

| Drift*2 | Standard range | Zero : ±2.0% of full scale/week | ||||

| Span : ±2.0% of full scale/week | ||||||

| Optional range | Varies by specification | |||||

| Response time (from inlet of analyzer) | — | T90 within 20 seconds T90 within 40 seconds (TIA optional range) | ||||

| Sample gas Condition | Gas composition | Flameproof enclosures | O2 : 21% or less, no mist, no dust The hazardous must be equivalent or less with electrical apparatus group Ⅱ B, gas and vapor-air mixture corresponding to temperature code T4, and Hydrogen-air mixture. | |||

| Pressurized apparatus | O2 : 21% or less, no mist, no dust The ignition temperature must be equivalent or less with electrical apparatus of gas and vapor-air mixture corresponding to temperature code T4. | |||||

| Pressure | Over 1.98 kPa | |||||

| Flow rate | Approx. 500 mL/min. | |||||

| Temperature | Ambient temperature | |||||

| Exhaust | Atmosphere pressure | |||||

| Materials in contract with sample gas | SUS304, SUS316, FKM, CaF2, Au, etc. | |||||

| Calibration method | Standard : Manual correction, Option : Automatic correction | |||||

| Analog output | Output content / Output specifications | 1 concentration output channel / DC 4 to 20 mA (DC 0 to 16 mA / 0 to 20 mA, DC 0 to 1 V / 0 to 5 V / 1 to 5 V / 0 to 10 V optional) | ||||

| Alarm setting | Arbitrary setting is available with span range from -10% to +110% of output for current and voltage. Negative output values set to zero. | |||||

| Contact Input-output (option) | 6 channels | |||||

| Digital connection (option) | Interface | RS-485 | ||||

| Protocol | Modbus-RTU | |||||

| Communication speed | Selected from 19200 bps / 9600 bps / 4800 bps / 2400 bps / 1200 bps | |||||

| Environment conditions | Location | Indoors | ||||

| Operational Temperature | -5 to 40 °C (away from direct sunlight and radiant heat) | |||||

| Humidity | 90% or less | |||||

| Vibration | Avoid large vibration sources (less than 100 Hz; 0.3 m/s2) | |||||

| Utility | Protective gas for Pressurized apparatus composition | Gas composition : N2, Gas pressure : 196 to 690 kPa, Gas flow rate : 10 L/min. (when purging), 500 mL/min. (when operating) Dew Point : -30°C Saturated or less | ||||

*1 Please consult HORIBA for measurement of the other components. *2 Guaranteed at normal ambient temp. ±5°C

■Recommended Measuring Ranges

| EIA-51d/51p | TIA-51d/51p | |||

|---|---|---|---|---|

| Min. Range | Max. Range | Min. Range | Max. Range | |

| CO | 0 to 0.21% | 0 to 100% | 0 to 50 ppm | 0 to 2000 ppm |

| CO2 | 0 to 0.11% | 0 to 100% | 0 to 50 ppm | 0 to 1000 ppm |

| CH4 | 0 to 0.21% | 0 to 100% | 0 to 50 ppm | 0 to 2000 ppm |

| C3O8 | 0 to 0.051% | 0 to 100% | 0 to 50 ppm | 0 to 500 ppm |

| NO | 0 to 0.21% | 0 to 100% | 0 to 100 ppm | 0 to 2000 ppm |

| SO2 | 0 to 0.051% | 0 to 100% | 0 to 100 ppm | 0 to 500 ppm |

Please consult HORIBA for applications other than those listed above.

| Model | TCA-51d | TCA-51p | MPA-51d | MPA-51p | PMA-51d | ||

|---|---|---|---|---|---|---|---|

| Type of protection | Exd Ⅱ B+H2T4 | Expxd Ⅱ T4X | Exd Ⅱ B+H2T4 | Expx Ⅱ T4X | Exd Ⅱ B+H2T4 | ||

| Flameproof enclosures | ● | ● | ● | ||||

| Pressurized apparatus | ● | ● | |||||

| Measuring principle | Thermal Conductivity Detector Method (TCD) | Paramagnetic (magneto-pneumatic type) | Paramagnetic (dumb-bell type) | ||||

| Component | H2 | O2 | |||||

| Measurement range | Minimum range | 0 to 10 vol% | 0 to 5 vol% | ||||

| Maximam range | 0 to 100 vol% | 0 to 25 vol% | |||||

| Optional | 0-1 to within less than 10 vol% 100-90 to 50 vol% | 0-1 to within less than 5 vol% | — | ||||

| Range Ratio | — | Max.1:25 Max.4 range | Max.1: 5 | ||||

| Performance | Repeatability | Standard range | Zero : ±1.0% of full scale | Zero : ±0.5% of full scale | Zero : ±0.1 vol% O2 | ||

| Span : ±1.0% of full scale | Span : ±0.5% of full scale | Span : ±0.1 vol% O2 | |||||

| Optional range | Zero : ±1.0% of full scale | Zero : ±1.0% of full scale | — | ||||

| Span : ±1.0% of full scale | Span : ±1.0% of full scale | ||||||

| Linearity | ±1.0% of full scale | ||||||

| Drift*2 | Standard range | Zero : ±2.0% of full scale/week | Zero : ±1.0% of full scale/week | Zero : ±0.05% vol% O2/week | |||

| Span : ±2.0% of full scale/week | Span : ±2.0% of full scale/week | Span : ±0.05% vol% O2/week | |||||

| Optional range | Varies by specification | Zero : ±1.0% of full scale/week | Varies by specification | ||||

| Span : ±3.0% of full scale/week | |||||||

| Response time (from inlet of analyzer) | T90 within 20 seconds | ||||||

| Sample gas Condition | Gas composition | Flameproof enclosures | O2 : 21% or less, no mist, no dust The hazardous must be equivalent or less with electrical apparatus group Ⅱ B, gas and vapor-air mixture corresponding to temperature code T4, and Hydrogen-air mixture. | ||||

| Pressurized apparatus | O2: 21% or less, no mist, no dust The hazardous must be equivalent or less with electrical apparatus of group Ⅱ C gas and vapor-air mixture corresponding to temperature code T4. | O2: 21% or less, no mist, no dust The ignition temperature must be quivalent or less with electrical apparatus of gas and vapor-air mixture corresponding to temperature code T4. | |||||

| Pressure | Over 1.98 kPa | 14.7 to 24.5 kPa | Over 1.98 kPa | ||||

| Flow rate | Approx. 500 mL/min. | Approx. 1.5 L/min | Approx. 300 mL/min | ||||

| Temperature | Ambient temperature | ||||||

| Exhaust | Atmosphere pressure | ||||||

| Materials in contract with sample gas | SUS304, SUS316, FKM, glass, SiO2, AU | SUS304, SUS316, FKM | SUS304, SUS316, Pt, glass, FKM | ||||

| Calibration method | Standard : Manual correction, Option : Automatic correction | ||||||

| Analog output | Output content / Output specifications | 1 concentration output channel / DC 4 to 20 mA (DC 0 to 16 mA / 0 to 20 mA, DC 0 to 1 V / 0 to 5 V / 1 to 5 V / 0 to 10 V optional) | |||||

| Alarm setting | Arbitrary setting is available with span range from -10% to +110% of output for current and voltage. Negative output values set to zero. | ||||||

| Contact Input-output (option) | 6 channels | ||||||

| Digital connection (option) | Interface | RS-485 | |||||

| Protocol | Modbus-RTU | ||||||

| Communication speed | Selected from 19200 bps / 9600 bps / 4800 bps / 2400 bps / 1200 bps | ||||||

| Environment conditions | Location | Indoors | |||||

| Operational Temperature | -5 to 40°C (away from direct sunlight and radiant heat) | ||||||

| Humidity | 90% or less | ||||||

| Vibration | Avoid large vibration sources (less than 100 Hz; 0.3 m/s2) | ||||||

| Utility | Protective gas for Pressurized apparatus composition | Gas composition : N2, Gas pressure : 196 to 690 kPa, Gas flow rate : 10 L/min. (when purging), 500 mL/min. (when operating) Dew Point : -30°C Saturated or less | |||||

*1 Please consult HORIBA for measurement of the other components. *2 Guaranteed at normal ambient temp. ±5°C

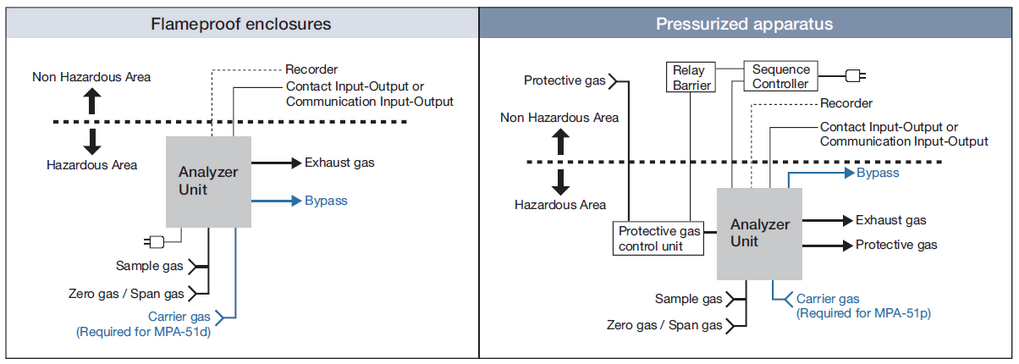

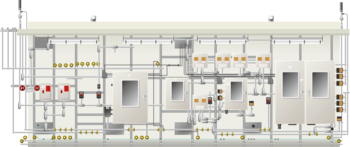

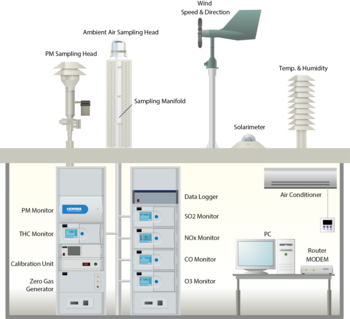

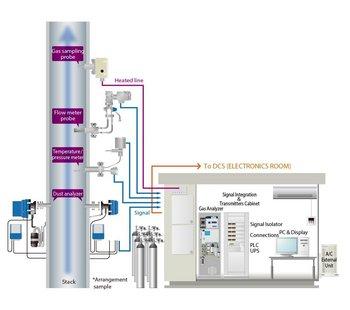

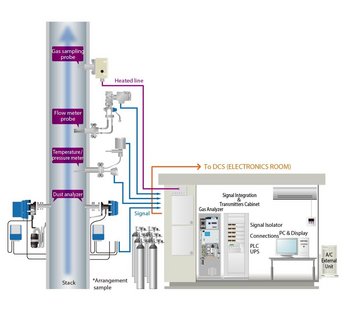

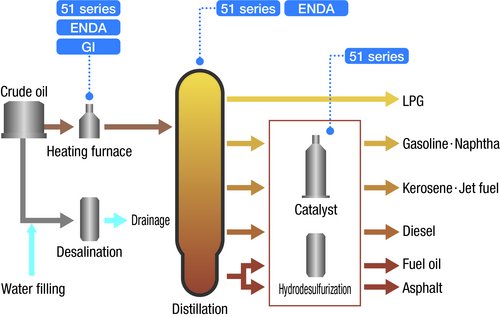

■System configuration