Lab Grown Diamond & its manufacturing Process

Lab grown diamonds are more prevalent in today’s jewelry industry due to technological advancements in Chemical Vapor Deposition (CVD), a newer and easier method compared to traditional synthetic diamond growing methods such as the High Pressure, High Temperature (HPHT) method which attempts to mimic natural diamond formation conditions that occur in the earth’s mantle.

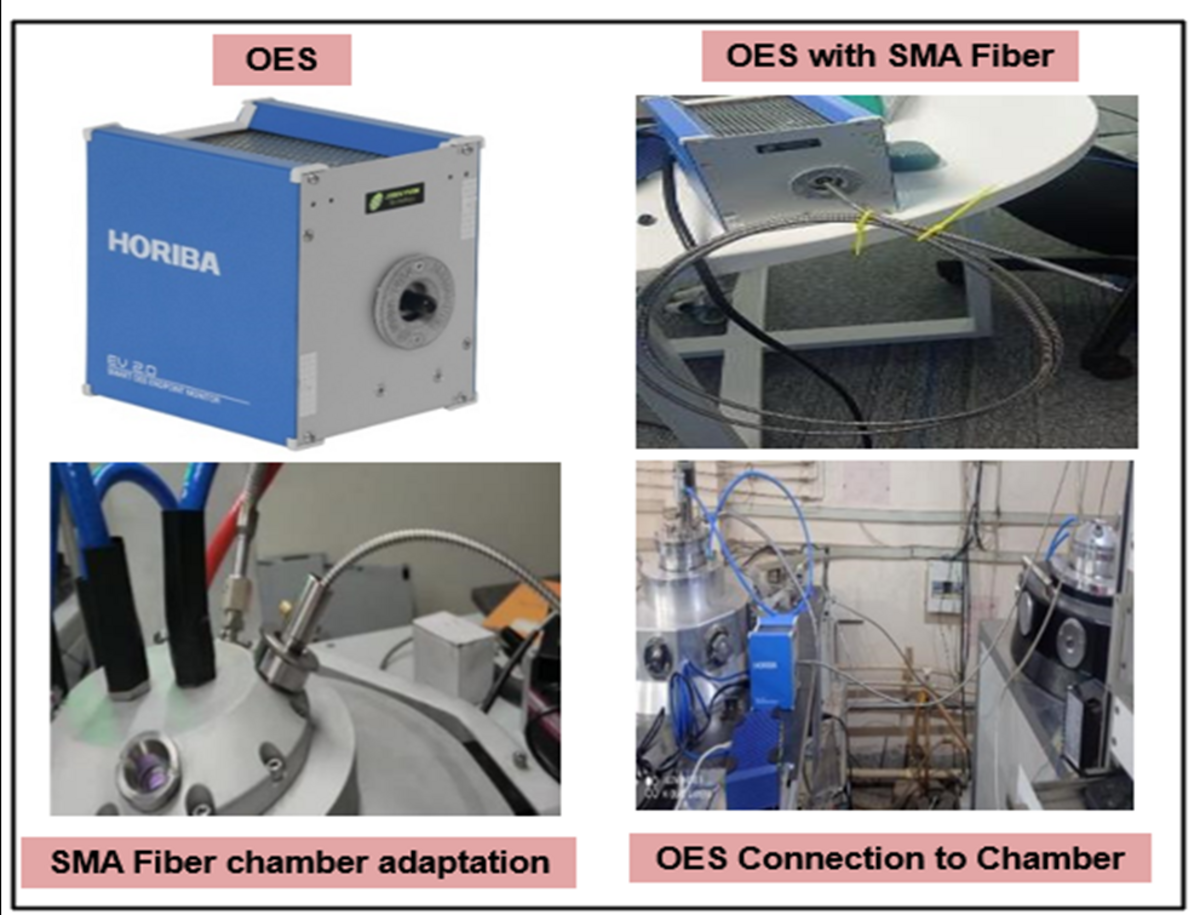

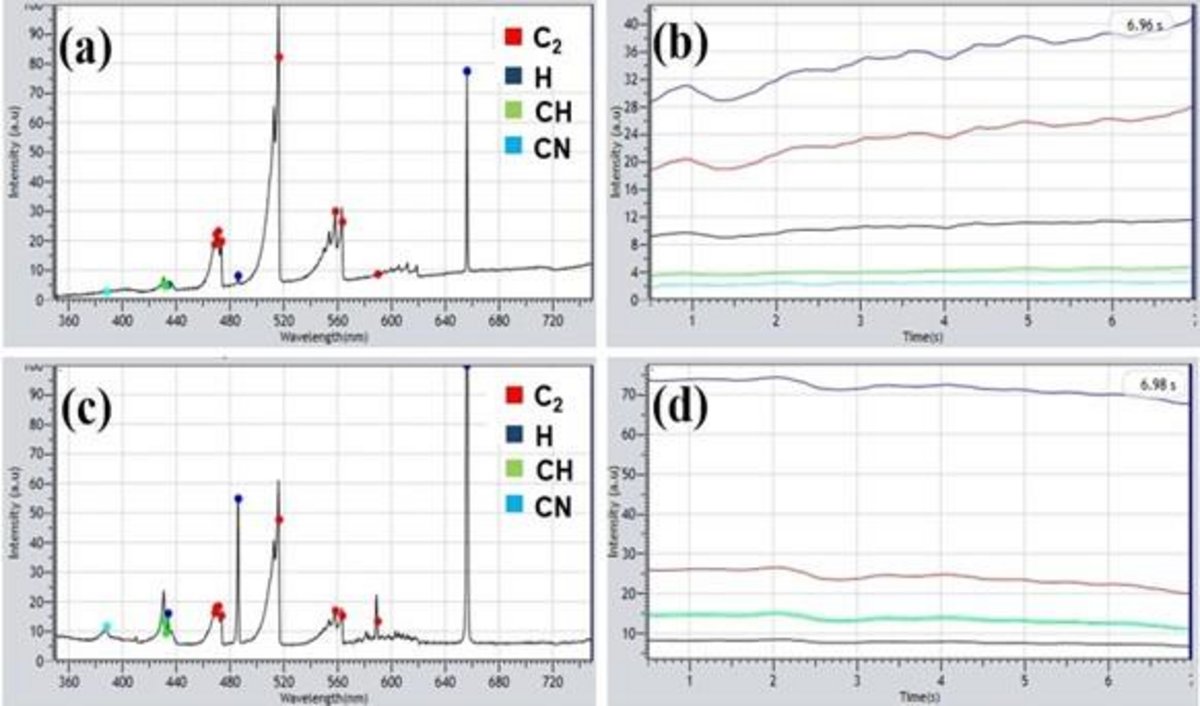

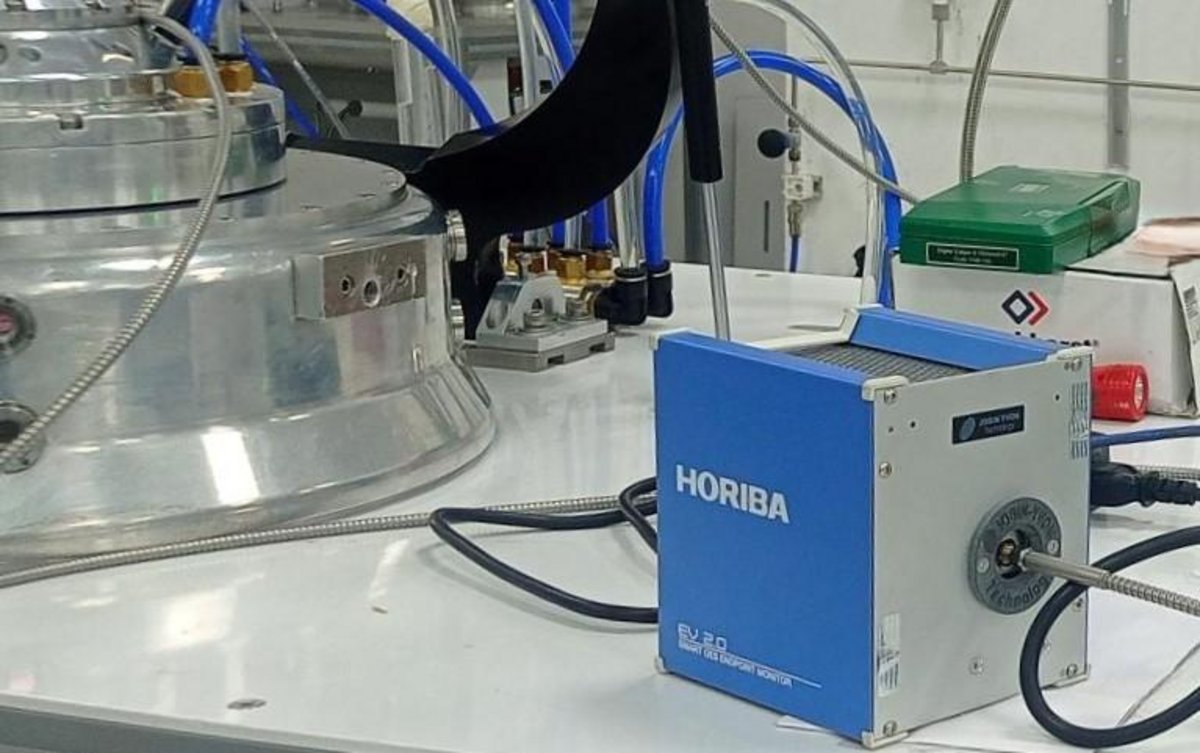

MPCVD (Microwave Plasma Chemical Vapor Deposition) process is used primarily for lab grown diamonds. The process involves placing a small diamond seed in a vacuum chamber, introducing carbon carrier gas into the chamber, and applying microwave energy to dissociate the gas molecules into carbon atoms which then deposit onto the diamond seed, layer by layer forming a diamond.