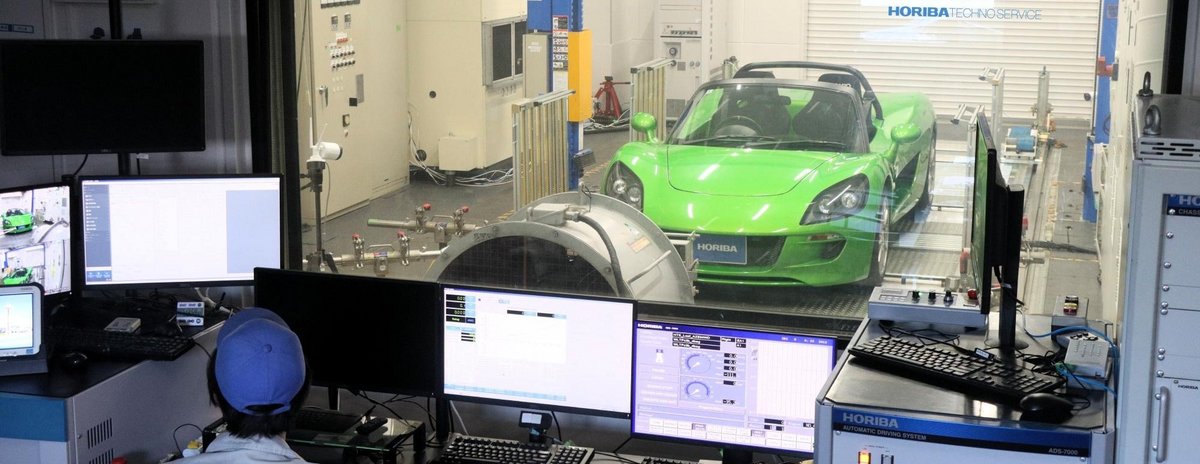

HORIBA’s Techno Service (HTS) facility in Japan delivers integrated automotive testing services spanning vehicle evaluation, component analysis, material characterization, and advanced scientific testing, all supported by HORIBA’s world-class measurement technologies and decades of engineering expertise.

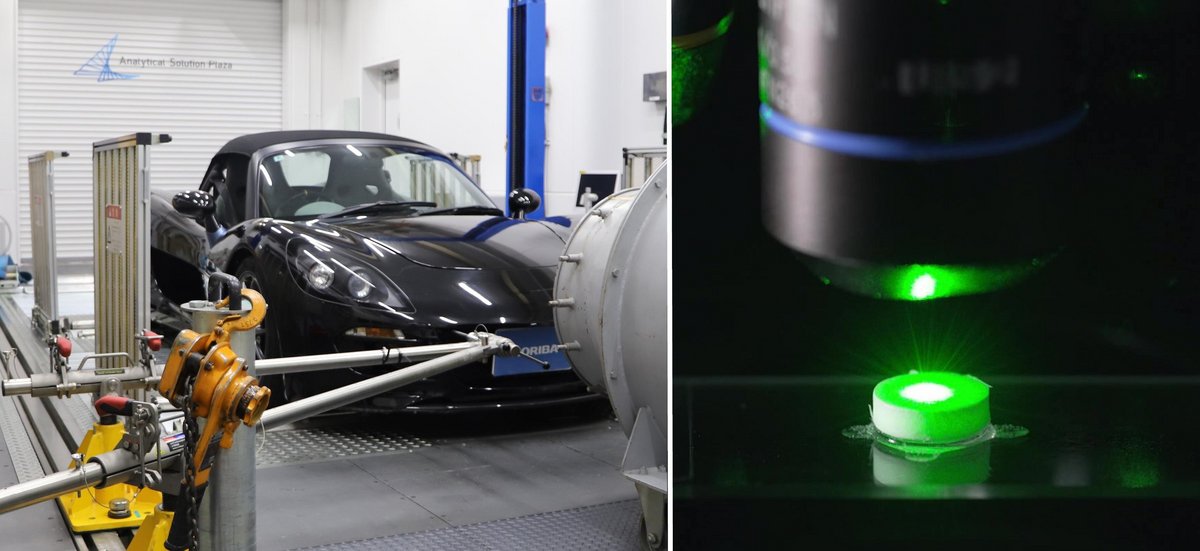

With the opening of the Vehicle Test Cell (VTC) and the expansion of the Analytical Solution Plaza (ASP), HORIBA provides a seamless ecosystem where vehicle testing connects directly with chemical and materials analysis—accelerating customer development from concept to validation.

The HTS facility serves OEMs, suppliers, new mobility entrants, and innovators developing solutions for electric mobility, internal combustion engines, and next-generation energy systems.

Fully operational since 2025, the HTS Automotive Testing Center integrates vehicle testing, cell/module evaluation, chemical analysis, application engineering, and technical consultancy under one roof.

From vehicle-level testing to material-level diagnostics, HTS supports full R&D cycles for electric, hybrid, and internal combustion systems.

To explore the full range of capabilities and technical specifications.

HORIBA’s HTS center offers engineering and evaluation services that merge real-vehicle testing with scientific analysis, supporting development for:

Optimize Your Vehicle Development

Request a consultation to explore VTC testing capabilities.

Located adjacent to the VTC, ASP enables immediate analysis of vehicle-tested components, providing deeper engineering insights and faster iteration.

Core Capabilities

Core CapabilitiesThrough combined evaluation, ASP allows customers to connect vehicle performance with component and chemical behavior in real time, significantly accelerating R&D cycles.

HTS conducted full exhaust sulfur analysis—including TS, SO2, H2S, DMS, SO3, and HCl—to support CO2 capture truck catalyst development.

Performed using: chassis dyno testing, GC, IC, MEXA-1170SX, continuous measurement, and scientific analysis.

Using EMIA-Step, SPCS-ONE, and OBS-ONE-PM, HTS revealed PM generation mechanisms from oils, fuels, machining fluids, and tapes, enabling the development of future-low-PM oils and diagnostic standards.

HTS ensures safe and reliable test execution through:

HORIBA supports customers with cutting-edge digital solutions for planning, monitoring, and analyzing test operations.

Software Tools

| |

| STARS Automation: Enhance vehicle development and testing with scalable test automation software |

| INSIGHT Facility & Asset Management: Navigating ISO 9001 and ISO 17025 Compliance |

| STARS Enterprise: Design and build optimal solutions for your facility |

Digitize Your Testing Workflow

Schedule a demo of HORIBA automation solutions.

Looking for localized support in Japan?

Explore HORIBA Japan’s full range of mobility-related contract testing and analysis services. Visit HORIBA Japan: Vehicle & Battery Testing

HORIBA TECHNO SERVICE Co., Ltd.

Address: 2 Miyanohigashi, Kisshoin, Minami-ku, Kyoto, 601-8305, Japan

Tel: +81 75 325 5291

如您有任何疑问,请在此留下详细需求信息,我们将竭诚为您服务。