HORIBA supports the development of stationary fuel cells with a wide range of analysis and measurement technologies, including the measurement of impurity gases during fuel reforming, the effects of impurities on fuel cell materials, and the evaluation of overall fuel cell performance.

A stationary fuel cell is a device that generates electricity by reforming city gas or LPG to extract hydrogen (H2) and supply it to a fuel cell. The generated electricity and exhaust heat are supplied to homes, buildings, and factories near the installation site.

As a distributed power generation system for homes, buildings, and factories, the stationary fuel cells are expected to reduce CO2 emissions because of their high efficiency of fuel cell power generation and low transmission loss compared to conventional power generation system. Fuel cells for home use have already been commercialized and in recent years, fuel cells for commercial and industrial use have also begun to spread.

Various types of fuel cells such as SOFC, PEFC, and MCFC (Molten Carbonate Fuel Cell) are used depending on the application of the facility using electricity. For commercial and industrial use, biogas and hydrogen fuel cells are also in practical use.

Table of Contents

In the development of stationary fuel cells, it is necessary to measure impurity gases other than hydrogen during fuel reforming and analyze the effects of these impurities on the fuel cell materials. Furthermore, a comprehensive evaluation of the fuel cell is essential.

Our fuel cell test stations the Evaluator Series are ideal for testing and evaluating fuel cell cells, stacks, and systems for stationary applications. In addition to performance evaluation, durability evaluation and accelerated degradation tests are performed based on high safety standards.

HORIBA Solution >>

PEM Fuel Cell Testing Equipment Evaluator LT Series

Fuel Cell Test Equipment for SOFC Evaluator HT Series

Hydrogen Gas Analyzer HyEVO

Stationary fuel cell units that generate electricity with hydrogen from reformed city gas and other substances require desulfurization and CO (Carbon Monoxide) removal before and after the reformer in order to produce hydrogen with fewer impurities, which is necessary for fuel cells.

Real-time gas measurement of impurity gases contributes to equipment development and confirmation of normal operation of stationary fuel cell equipment for commercial and industrial use.

HORIBA Solution >>

For monitoring impurity concentration in highly concentrated hydrogen: Trace Gas Analyzer GA-370

Various gas analyzers that measure the concentration of impurity gases such as CO, CO2, and sulfur gases that lead to the life of fuel cells. Also, the water quality analyzers can measure the pH of waste water to determine the detorioration state of fuel cells. They both contribute to fuel cell development.

HORIBA Solutions >>

For monitoring impurity concentration in highly concentrated hydrogen: Trace Gas Monitor GA-370

For monitoring evolved gases: Multi-Component Gas Analyzer VA-5000 Series

For monitoring pH of wastewater: Micro Volume pH Monitor UP-100

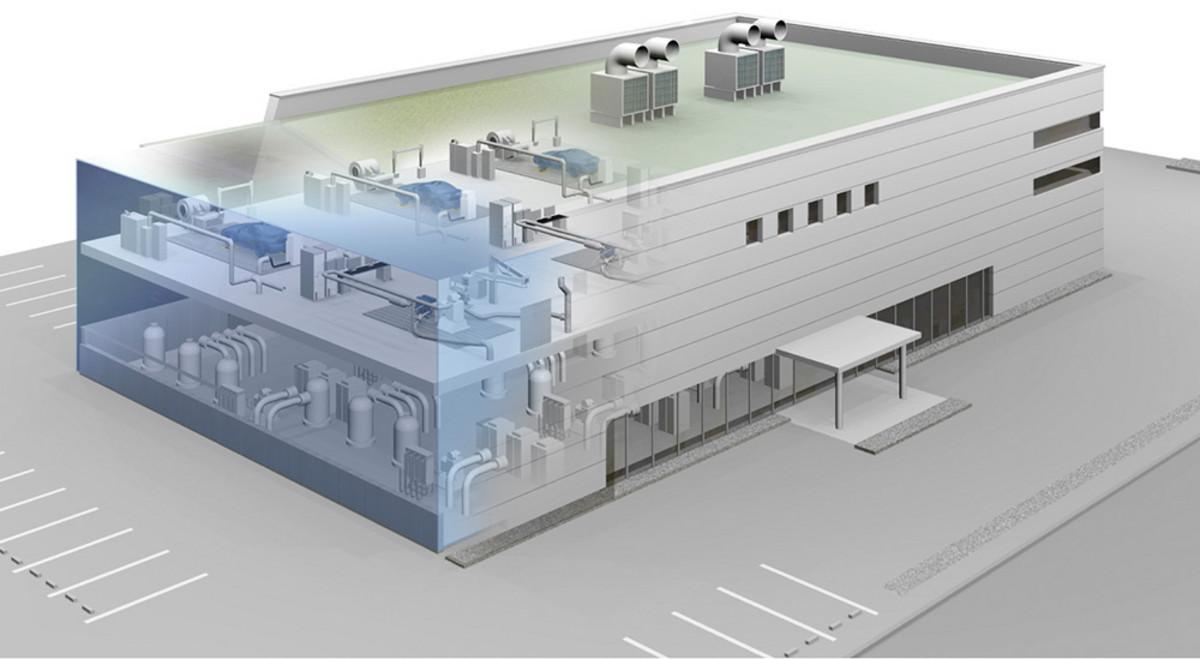

When launching a test building to handle hydrogen, more stringent safety measures are required than before.

Our turnkey solution, a total laboratory construction package, includes ordering multiple contractors, meetings to determine specifications, safety, process and quality control of construction, as well as post-introduction operation, maintenance, and work efficiency, all with an emphasis on safety and ease of use until just before the start of laboratory operations. We can handle the entire construction process on behalf of our busy customers.

When setting up a test facility that handles batteries and hydrogen, safety measures must be taken from a completely different perspective than for ordinary test facilities.

Our new unique risk assessment method classifies the relationships between systems from four perspectives (physical contact, energy transfer, information communication, and material transfer) to identify and address risks without omission, and to ensure safety and security while minimizing costs and time.

HORIBA Green Hydrogen Solutions

HORIBA VA-5000 Multi-component Process Gas Analyzer

High-Sensitive & Continuous Monitoring of Impurities in Hydrogen Gas with the HORIBA GA-370

Do you have any questions or requests? Use this form to contact our specialists.