Airborne molecular contaminants (AMCs) cause product quality issues in modern semiconductor production, even at extremely low ppb concentrations. AMCs first became an issue with the introduction of chemically amplified resists in the 1990s. A defect occurred once the photolytically initiated acids within the resist were neutralized by airborne ammonia (NH3) from cleanroom. This interaction is device defect relevant as it deteriorates line width and line structures. Therefore, measurement of ammonia airborne molecular contamination in cleanroom became common, and Ion Chromatography has been used for a long time.

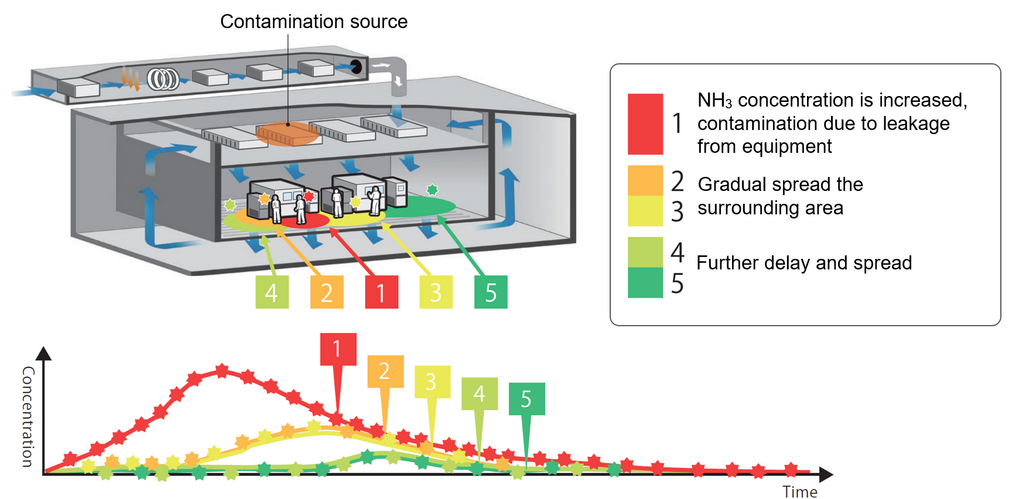

Ammonia contamination in the cleanroom may come from different, sometimes unexpected sources: outside air intake, evaporation from personnel or leakage from the equipment. Time to time there are random events leading to the increase of ammonia concentration and resulting in haze on optical surface of reticles and mirrors. However, it is problematic to rapidly identify and eliminate the source of ammonia contamination before affecting production yields, as it may come from anywhere.

Manual analysis of AMCs does not provide high spatial resolution and may delay with the detection of contamination, resulting in the spread of contamination through the cleanroom and leading to the yield deterioration.

In order to minimize the yield loss caused by ammonia airborne molecular contamination, it is highly important to obtain analysis data with high spatial resolution for quick determination of contamination source and immediate countermeasures.

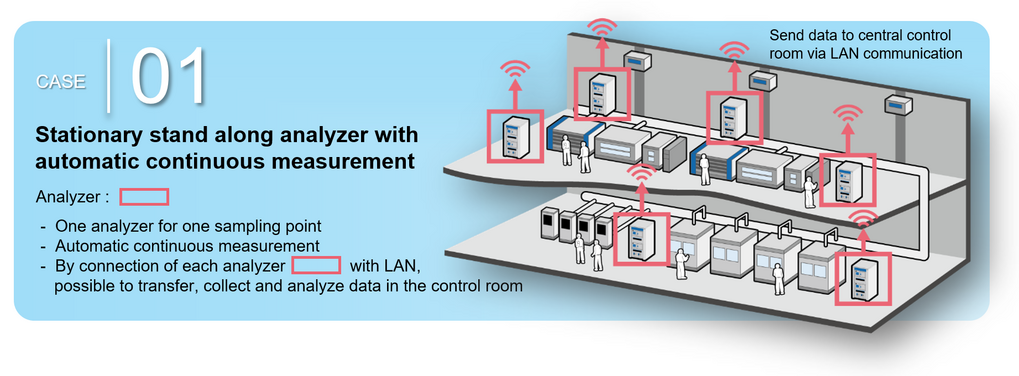

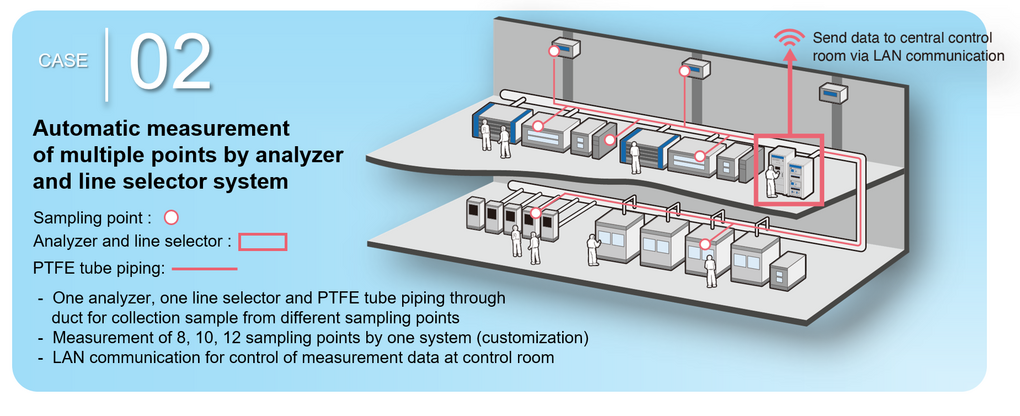

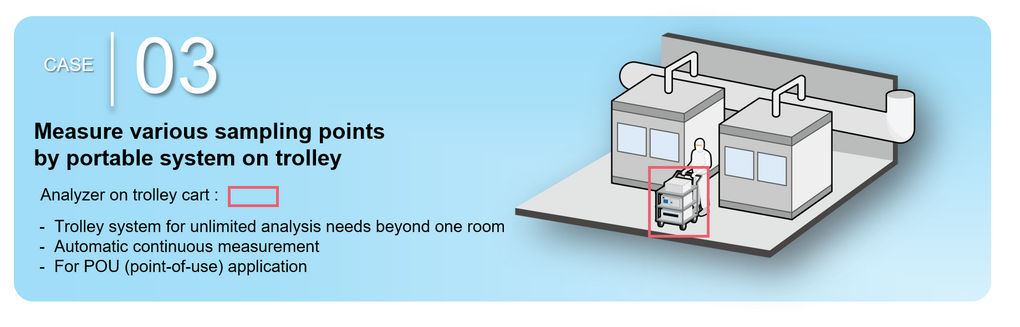

AMC Monitoring System

In the cleanroom, where AMC analysis is performed manually, sampling only at point [5] of Figure 1 may cause a delay in detection of contamination and spread of AMC trough the whole cleanroom. HORIBA multi-point measurement system composed from Line Selector and AMC Monitoring System with multiple sampling points [1] [2] [3] [4] [5] at Figure 1 allows to increase spatial resolution of analysis, which leads to the early detection of AMC source and rapid countermeasures. Such multipoint AMC monitoring system may contribute to the improvement in production yields, device quality and reliability.

Figure 1 Multi-point AMC Monitoring

Ammonia Monitor

Do you have any questions or requests? Use this form to contact our specialists.