| Name | Process Laser Gas Analyzer |

| Model | PLGA-1000 |

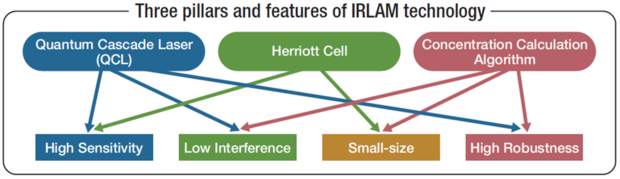

| Measurement principle | NDIR: Non Dispersive Infrared |

| Light source | QCL: Quantum Cascade Laser |

| Laser class | Class 1(IEC 60825-1:2014) |

| Components | Methane ( CH4 ), Ethane ( C2H6 ), Acetylene ( C2H2 ), Carbon Dioxide ( CO2 ) |

| Range*¹ | CH4 : 0 - 2000 ppm or 0 - 5 vol% C2H6 : 0 - 50 vol% C2H2 : 0 - 50 ppm CO2 : 0 - 200 ppm |

| Repeatability | ±1.0 % full scale |

| Linearity | ±1.0 % full scale |

| Response time | Td + T90 : 3 sec at flow rate of 1.6L / min |

| ZERO drift | ±2.0 % full scale per 1 month |

| SPAN drift | ±2.0 % full scale per 1 month |

| Data update cycle | 1 sec |

| Calibration interval | 1 month |

| Ambient temperature | -10˚C to 50˚C or -10˚C to 45˚C (no direct sun rays, including case temperature influences due to radiant heat and heat conduction) *The flow rate of the protective gas differs depending on the specification of the ambient temperature |

| Protection class | IP66、NEMA4X |

| Hazardous area classification | US, Canada: Class I, Division 2, Groups A, B, C, D T4 US: Class I, Zone 2, AEx pzc IIC T4 Gc IECEx, Canada: Ex pzc IIC T4 Gc ATEX, UKCA: |

| Wetted materials | SS316, SS304, BaF2, FKM, PTFE, Au, Ni |

| Gas connector size | 1/4"NPT, 1/2"NPT (Option: N2 generator) |

| Pressure error alarm output | Three channels (Main enclosure, Optical unit, Cell) DC 5 V to 24 V, 1 A at each terminal |

| Communication function | Modbus®/ TCP |

| Analog output | Four channels (Gas concentration) 4 mA to 20 mA Max. load: 550 Ω |

| Contact output | Three channels (Calibration / Main alarm / Measurement) Relay contact output (isolated output) DC 5 V to 24 V, 1 A at each terminal |

| Digital output | One channel (For signal barrier power control relay) DC 24 V, 100 mA |

| Dimension | 664 mm (W) x 270 mm (D) x 704 mm (H) *Protrusions included |

| Weight | Standard 46 kg, Max. 50 kg *Depends on product specifications |

| Power supply | AC 100 V to 120 V, 50 Hz/60 Hz or AC 200 V to 240 V, 50 Hz/60 Hz |

| Power consumption | Max. 250 VA |

*¹ Please contact us for other components.

Modbus is a trademark of Schneider Electric USA Inc.