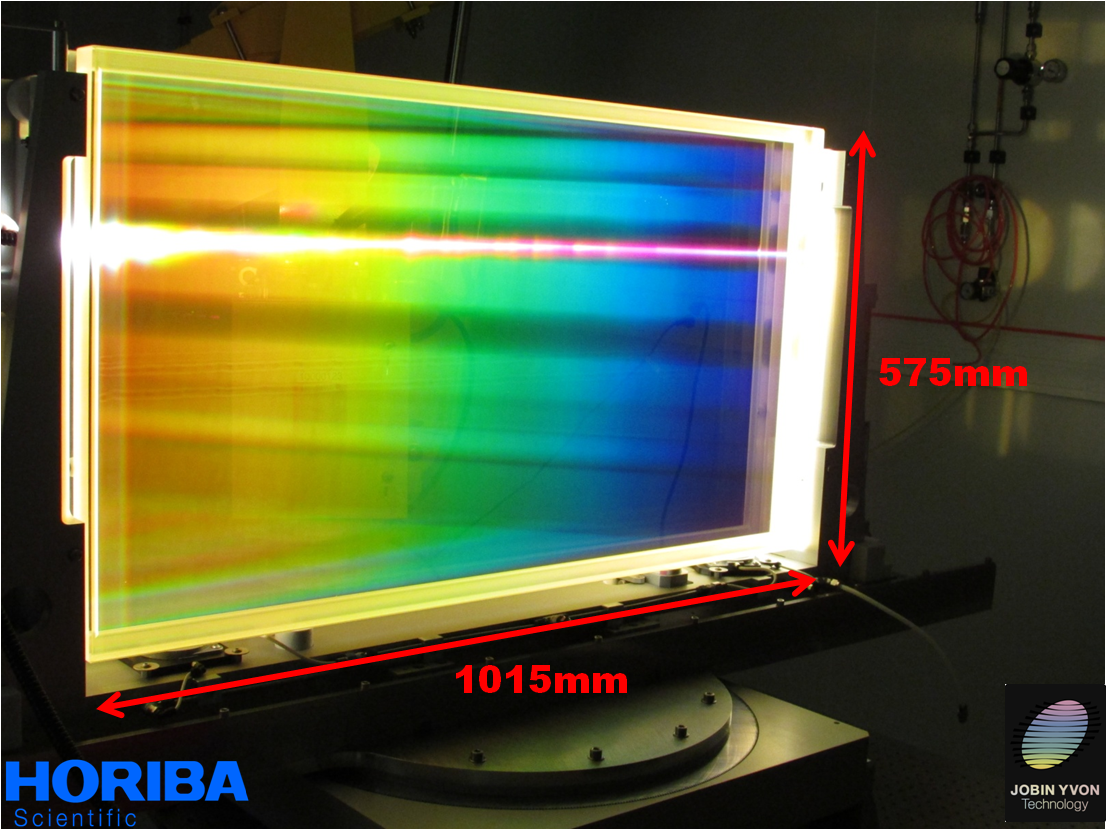

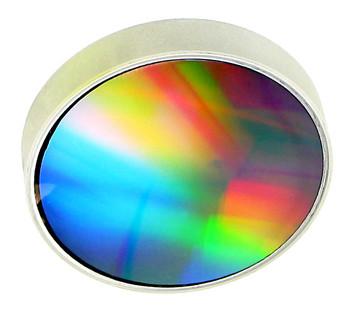

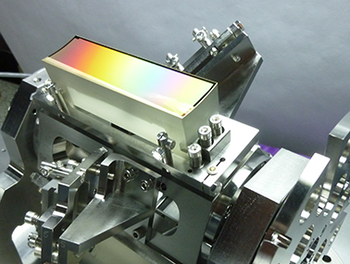

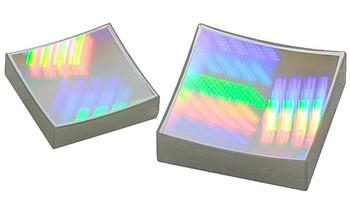

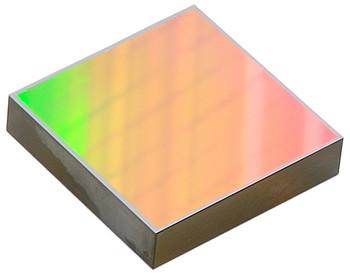

In CPA lasers where the highest optical performance and damage thresholds are required, a master gold-coated holographic grating ensures best performances. Master gratings are the technology of choice for large-area gratings, and HORIBA currently supplies a large range of several standard sizes up to meter-size. Standard groove densities include 1200, 1480 and 1740 lines/mm, for operation in the spectral range from 600 nm to 1600 nm. Custom sizes can be considered up to 1500 mm, and alternate groove densities, non-standard wavelength optimization, and/or larger grating sizes will be reviewed upon request.