For over 30 years HORIBA Medical has been designing, manufacturing and marketing high performance hematology diagnostic systems for laboratories and hospitals. This expertise has made the company one of the world leaders in the in vitro diagnostics sector. Market trends, the rise of new competitors and historical patents falling into the public domain, have always led HORIBA Medical to develop new, innovative solutions to stay ahead of the game and remain competitive.

Today, to carry out a complete blood count (hemogram), a fully automated analyzer takes less than a minute, from extracting the material from the tube with different types of captors, to chemical preparation, characterization and counting of the different blood cells, search for immature or pathological cells and finally, analysis and transmission of the result. Such analyzers, deployed in hospitals or large technical platforms in particular, are also subject to usage constraints such as, for example, the high rate or the complete automation of the diagnostic. This therefore requires counting a large number of cells in a very short time, which generates very complex multi-physical conditions.

HORIBA Medical continuously develops ever more high-performance products, widening our product offer. Improving speeds and the use of instruments, detecting specific pathologies, contributing to a better understanding of measurements at the cell level and deploying POCT (Point of Care Testing) instruments are some of the strategic directions being followed, requiring us to address new issues such as integrating a compact and robust design for our systems.

In order to broaden its expertise and meet these new challenges, HORIBA Medical has therefore decided to develop the digital simulation activity within its Innovation and Development center for several years, relying on the COMSOL Multiphysics® simulation software in particular.

Classically in the biomedical industrial sector, experimental approaches are favored. However, these methods are limited, notably with regards to the complexity of biomechanical and physicochemical phenomena which enter into play for blood analyzers. This is where digital modeling steps in.

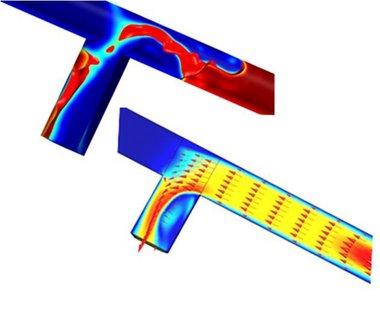

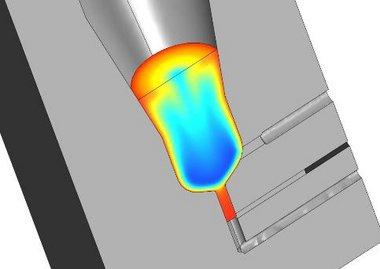

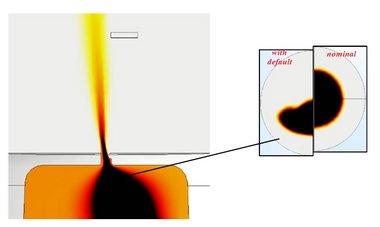

HORIBA Medical has chosen to use COMSOL Multiphysics® and its CFD, Heat Transfer, AC/DC and Microfuidics modules to better understand the physical phenomena related to the architecture of systems and their geometries, with a goal of obtaining optimal design and performance.

More precisely, developing hematology systems implies taking numerous phenomena into account: physical, electric, optical, hydraulic, chemical, thermal and microfluids plus their related interactions.

For example, with regards to electrics, cells pass through a micro-orifice between electrodes (Coulter principle) to measure the resulting impedance and count the cells. The task is delicate in view of the 5 million red cells present in a microliter of blood. Furthermore, optical benches are used to differentiate between cells based on their intra-cellular content. Transfer of material through the channels is carried

out by fluid flow, the properties of which can sometimes be complex.

With regards to chemistry, specific reagents have been designed in relation to the populations to be measured. Thermal factors have a major influence, so it is essential to control these and regulate temperatures. Finally, microfluid studies are required for new miniaturized hematology systems which are much more compact than existing products and consequently require flow analysis on a micro-metric scale.

HORIBA Medical also uses COMSOL Multiphysics® tools to create (Application Builder) and deploy (COMSOL Server, COMSOL Compiler) applications internally. The aim is to make engineers and integrators increasingly autonomous in using modeling to develop new prototypes.

Recently, dedicated applications have been made directly accessible on workstations enabling parameter adjustments of models until the required results are achieved. This does not eliminate the development of prototypes and the related testing but reduces the number of tests and enables development of highly optimized designs.

In conclusion, COMSOL Multiphysics® is an essential tool for greater efficiency in the design of complex systems.

COMSOL is a global supplier of simulation software for design and research in industry, research laboratories and universities. COMSOL Multiphysics® is an integrated software suite for creating models based on physical properties and simulation. Its particular strength lies in its capacity to process multiphysical phenomena. Modules can be added to the simulation platform to process electromagnetics, mechanics, thermal effects, fluids and chemistry. Integration of COMSOL Multiphysics® with market leading calculation and CAD tools is assured through dedicated interfaces. Simulation experts use COMSOL Compiller™ and COMSOL Server™ to deploy their applications to design teams, production departments, test laboratories and their clients all over the world. Established in 1986, COMSOL employs over 450 persons in 19 offices worldwide and is extending its reach through a network of distributors.

~

COMSOL, COMSOL Muptiphysics, LiveLink, COMSOL Compiler, COMSOL Runtime and COMSOL Server are registered trademarks of COMSOL AB. For other trademarks, see www.comsol.com/trademarks.