HORIBA supports customers' development and manufacturing with a wide range of technologies, from powertrain evaluation of fuel cell vehicles (FCEVs or FCVs) to solutions for efficient system calibration, as well as engineering services for prototyping a single vehicle.

Hydrogen fuel cells are one of the most promising zero-emission green technologies and offer many advantages over combustion engines, with up to 60% efficiency in converting the chemical energy of the fuel into electrical energy.

In developing FCEVs, it's crucial to optimize the fuel cell's performance as a power source and safely integrate it into the powertrain system. This development process needs advanced evaluation systems for everything from individual components such as fuel cells and motors to the entire powertrain and vehicle. Additionally, these evaluations must be conducted appropriately and efficiently.

Table of Contents

A major challenge is to make energy available more efficiently, more stably, and at lower cost. In the development of automobiles, the systems that make up the vehicle have become significantly more complex, including electrification of the vehicle with fuel cells and batteries, as well as hybrid systems that also use internal combustion engines. As a result, issues have emerged that significantly bloat development man-hours. The key to solve this issue is the efficient optimization of systems.

Many countries are stepping up their efforts to electrify its vehicles in order to realize a carbon-neutral society. The requirements for fuel cell stack components and materials, such as quick output response, are becoming higher especially for FCEVs. In addition, temperature control of fuel cell stacks is also an important issue to improve fuel cell efficiency and reduce fuel cell degradation. While Japan leads the developments for light duty FCEVs, Europe, the U.S. and China, the fuel cell system is expected to be used in heavy duty vehicles which will require high durability.

We provide total solutions for overall development and evaluation of FCEVs and other electric vehicles, from components to vehicle systems, by combining our long-years of engine and drivetrain measurement technology with newly acquired fuel cell and battery measurement technology, as well as, gas measurement, liquid monitoring and other technologies.

Fuel Cell Test System Evaluator Series are ideal for testing and evaluating from single cell to full stack and fuel cell systems for mobility applications. In addition to performance evaluation, durability evaluation and accelerated degradation tests are performed based on high safety standards.

Evaluator Series analyzes the behavior of cells and stacks of fuel cell to optimize fuel cell system design. In addition, Hardware-in-the-Loop Simulation (HiLS) can simulate the load effects of fuel cell systems.

Especially for FCEV development, HORIBA's long-standing knowledge of powertrain and driveline development and HORIBA FuelCon's comprehensive expertise in automotive fuel cells can also be used to create test environments for small and large FCEV powertrain development. For more information, please check Turnkey Solutions and Risk Assessment.

HORIBA Solution >>

Fuel Cell Test System Evaluator Series

The purity of hydrogen for FCEVs is defined by ISO 14687-2 as 99.97% or higher. When hydrogen is purified by reforming city gas at an on-site hydrogen station, impurities in the hydrogen must be measured periodically. HORIBA contributes to the production of high-quality hydrogen for FCEVs at on-site hydrogen stations with equipment that measures and monitors impurity gases (CO, CO2, sulfur components, etc.) in hydrogen in real time.

HORIBA Solution >>

We offer Test in the Loop™*, a development concept for evaluating components and vehicle systems under realistic operating conditions by freely connecting actual equipments or models of batteries, motors, powertrains, engines, and vehicles as well as evaluation equipment. Test in the Loop enables highly accurate performance verification and optimization of components and systems during the vehicle development and design phase.

*Test in the Loop is a trademark or registered trademark of HORIBA, Ltd.

HORIBA MIRA provides engineering services to bring energy-efficient electric and hybrid vehicles, products and systems to market. HORIBA MIRA has the experience in supporting vehicle design, development, and validation with specialized skill sets and tools and help minimize cost, risk, and time throughout the development cycle.

HORIBA Solution >>

Supporting Automotive Electrification Development and Accelerating Entry into the Electrification Market: Electrification/Energy Management

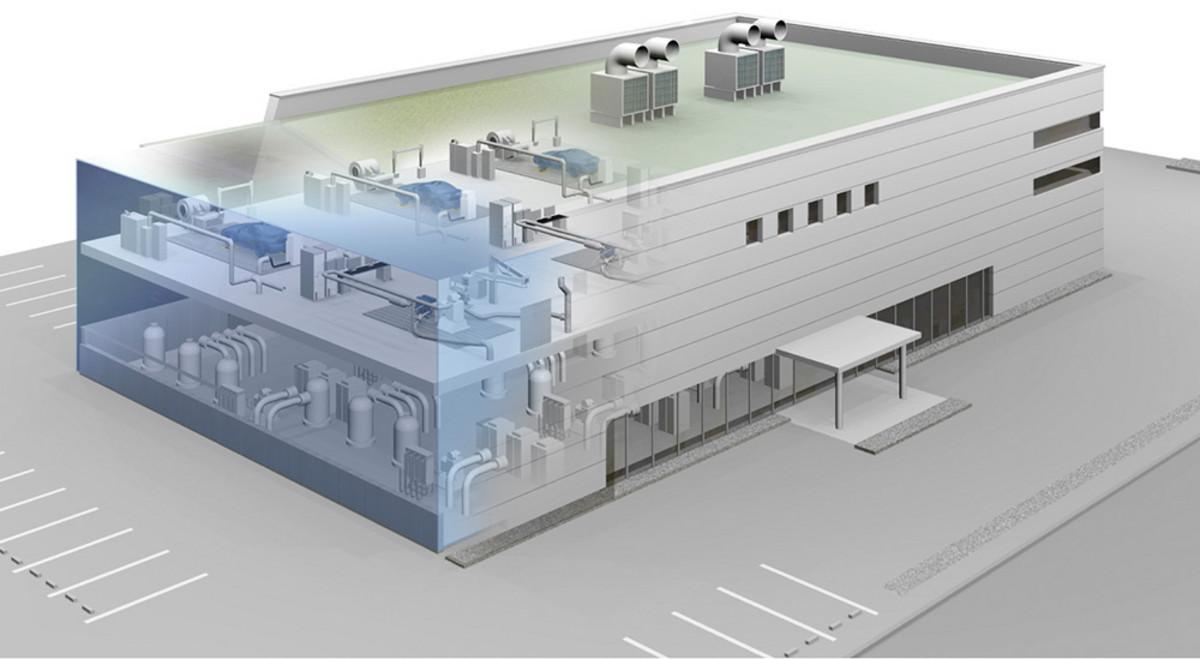

When launching a test building to handle hydrogen, more stringent safety measures are required than before.

Our turnkey solution, a total laboratory construction package, includes ordering multiple contractors, meetings to determine specifications, safety, process and quality control of construction, as well as post-introduction operation, maintenance, and work efficiency, all with an emphasis on safety and ease of use until just before the start of laboratory operations. We can handle the entire construction process on behalf of our busy customers.

HORIBA's Hydrogen Solutions

HORIBA STARS Enterprise Automotive Facility Management

Full Vehicle Testing - Solutions for Electrification Development and Testing by HORIBA

System Testing - Solutions for Electrification Development and Testing by HORIBA

Component Testing - Solutions for Electrification Development and Testing by HORIBA

Material Characterization - Solutions for Electrification Development and Testing by HORIBA

Powering the Future of Mobility - Fuel Cell Powertrain Solutions from HORIBA

Electrification Beyond Measure - EV System and Vehicle Testing Solutions Webinar by HORIBA

Electrification Beyond Measure - EV Material and Component Testing Solutions Webinar by HORIBA

Electrification Beyond Measure - Electrification Development and Testing Solutions Webinar by HORIBA

Application Laboratory Virtual Tour

Máte nějaké dotazy nebo požadavky? Pomocí tohoto formuláře kontaktujte naše specialisty.