Selectable option

| Model | Auto Cleaner | Crucible Loader | Auto Sampler | C-550 (Gas conversion) | ONH 3components | Customization / Special Acceptance |

|---|---|---|---|---|---|---|

| ✔ | ✔ | ✔ | ||||

| EMGA-Expert | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

Click here for more information.

Specifications

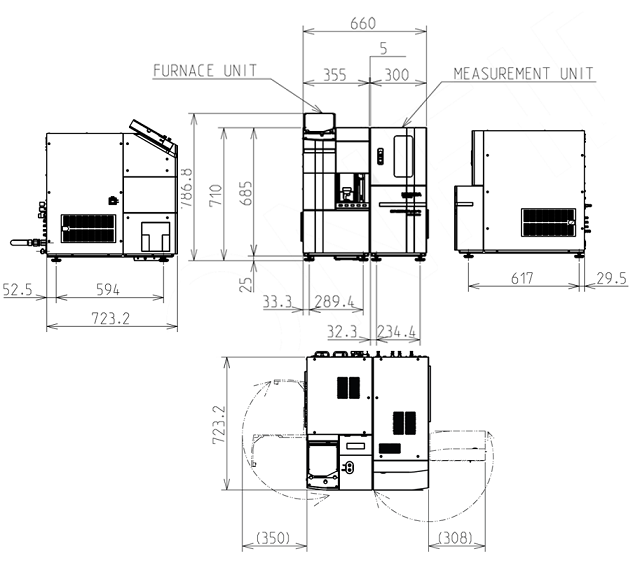

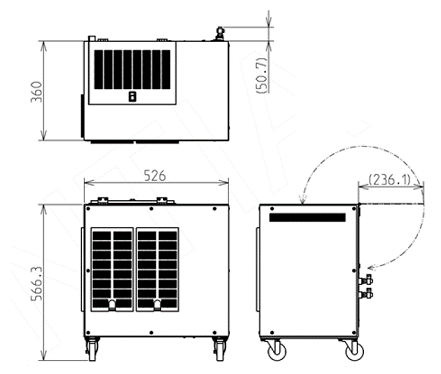

Dimensions

Oxygen/Nitrogen/Hydrogen Analyzer

(Flagship High-Accuracy Model)

The EMGA-Expert Oxygen/Nitrogen/Hydrogen Analyzer significantly reduces analysis time and costs while enhancing analysis accuracy and functionality. The EMGA series has been a best-selling model for over 40 years since its release in 1980, maintaining industry-leading analysis accuracy that strongly supports material research and development and quality control.

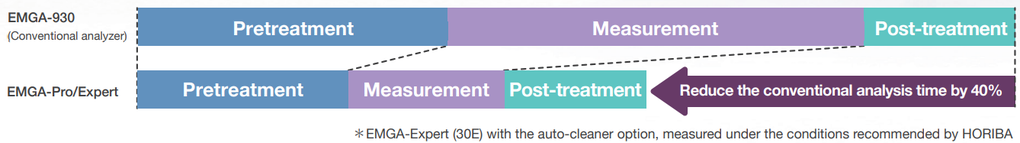

We have achieved a reduction of approximately 40% in analysis time and running costs compared to our previous model, through comprehensive efficiency improvements. It is also equipped with an automation mechanism to improve operator safety, and reduce operator working hours.

Typical Applications:

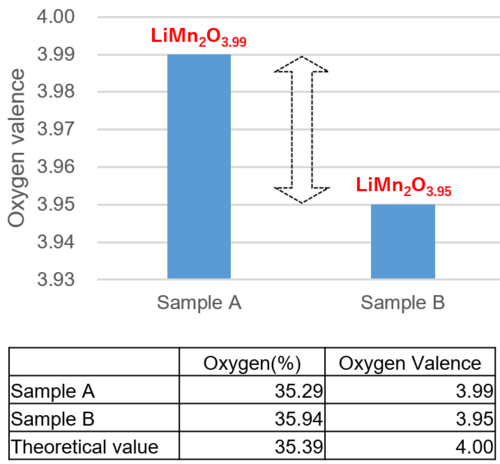

- Energy: Materials for lithium-ion battery, fuel cell, electrolyzer

- Electric parts

- Ceramics

- Semiconductor: Silicon, poly-silicon, GaN

- Steel and non-ferrous alloy (metallurgy): Iron, copper, nickel, aluminum, zinc, tungsten carbide

- Mineral: Cokes, lime stone, coal, silicone, rare-metal

- Others: Catalyst, rubber, carbon black, silica, cement

* For more entry-class applications, we also offer the EMGA-Pro (Entry Model).

"I need to reduce the time I have to spent on measurements. I do not want to make the post-process wait for my result."

HORIBA’ s proprietary sequence algorithm reduces the analysis cycle time compared to our conventional models, by optimizing the gas flow.* *patent applied

"I require my samples to be analyzed with precision, consistency, and reliability."

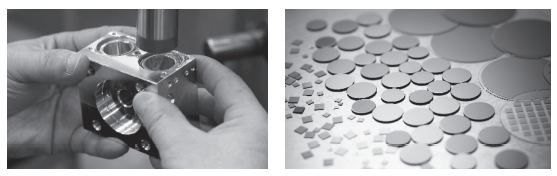

Proven NDIR Gas Detection Technology

The EMGA Series has NDIR gas detectors developed, designed, and manufactured by HORIBA. Based on detailed design and sophisticated production technology, these detectors are manufactured with close attention to all processes, from the polishing and assembly of components to adjustment and confirmation of stable operation. Our thorough quality control provides stable and highly reliable measurement for an extended period with the EMGA Series. In addition, we have also developed the TCD detector in-house so that these analyzers can demonstrate the best performance.

Please also refer the Measurement Principle page for the details.

"Less downtime, less running cost!"

Easy Replacement of Lower Electrodes* * Patent applied

With the new design for replacing the chip all you have to do is remove the lower electrode cap to replace the chip, without any special tool. This mechanism reduces the amount of time it takes to approximately 1/10.

New Dust Filter* * Patent applied

With the new mechanism for replacing the dust filter you only need to replace the thin filter inside the filter holder. This has also reduced the filter replacement frequency to 1/10 (replacement required after about 500 measurement cycles).

Significantly Reduced the Carrier Gas Consumption* * Patent applied

The number of measurements that can be performed with one gas cylinder has significantly increased from about 1,400 times to 2,300 times when a 47-liter cylinder is used.

Automation Options

We provide three optional automation units for streamlining your operation for the EMGA Series:

- Crucible Loader: Precise capture and positioning of crucibles by rotary mechanism. Maximum stock: 100 pcs.

- Auto Sampler: Samples and fluxes are automatically loaded (Up to 22).

- Auto Cleaner: Two rotating brushes clean the upper and lower electrodes after each measurement.

Please refer the Automation Options for the EMIA/EMGA Series Elemental Analyzers for the details.

Advanced Operation Software

The EMGA Series has its original operation software which prioritized ease of use, specifically in optimizing the layout, operating menus, and functions. Additionally, self-diagnostic monitoring was implemented to assess the connected device's status, an alarm function was integrated, and three navigators were expanded to improve daily operation.

Enhanced Operator Assistance

Additionally, the software includes a self-diagnostic monitoring feature to assess the status of connected devices, an alarm function, and three navigators to recommend the most suitable conditions for samples, troubleshoot errors, and alert users to perform maintenance. These features improve daily operation and ensure efficient analysis.

Watch the EMIA Series maintenance video

*The user interface and functionalities of the software for this system are the same with those of EMIA-Pro.

Máte nějaké dotazy nebo požadavky? Pomocí tohoto formuláře kontaktujte naše specialisty.

Hydrogen Analyzer

Oxygen/Nitrogen Analyzer (Entry Model)

Carbon/Sulfur Analyzer

(Flagship High-Accuracy Model)

Carbon/Sulfur Analyzer (Entry Model)

Carbon/Sulfur Analyzer (Tubular Electric Resistance Heating Furnace Model)

Confocal Raman & High-Resolution Spectrometer

Raman Spectroscope - Automated Imaging Microscope

X-ray Fluorescence Sulfur-in-Oil Analyzer

MicroRaman Spectrometer - Confocal Raman Microscope

Hydrogen Analyzer

Oxygen/Nitrogen Analyzer (Entry Model)

Field-installation type water quality measuring instruments

Field-installation type dissolved oxygen meter (DO meter)

Field-installation type optical dissolved oxygen meter (DO meter)

Field-installation type dissolved oxygen meter (DO meter)

Panel-mount type dissolved oxygen meter (DO meter)

HF (Hydrofluoric Acid) DO (Dissolved Oxygen) Monitor / Pure Water DO (Dissolved Oxygen) Monitor

Dissolved Oxygen Concentration Monitor Series for Semiconductor Manufacturing

Multi-parameter water quality checker

Explosion-proof Gas Analyzer

Air Pollution Monitor

Air Quality Monitor

Ambient Carbon Dioxide Monitor

Ambient Carbon Monoxide Monitor

Continuous Emission Monitoring System

Hydrogen Analyzer

Oxygen/Nitrogen Analyzer (Entry Model)

Carbon/Sulfur Analyzer

(Flagship High-Accuracy Model)

Carbon/Sulfur Analyzer (Entry Model)

Carbon/Sulfur Analyzer (Tubular Electric Resistance Heating Furnace Model)

Stack Gas Analysis System

Stack Gas Analyzer

Trace Gas Monitor

Stack Gas Analyzer

Vapor Concentration Monitor

High-grade type Gas Monitor for Chamber Cleaning End Point Monitoring

Laser scanning oil film detector

Motor Exhaust Gas Analyzer

Automotive Emission Analyzer

Motor Exhaust Gas Analyzer

On-board Emissions Measurement System

On-board NH3/N2O Measurement System for real-world driving

Oil concentration meter

Oil concentration meter

Portable Gas Analyzer

Hydrogen Gas Analyzer

Multi-Component Gas Analyzer