Measuring Principle

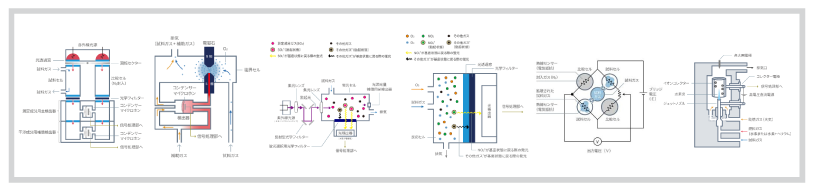

What is the Beta Ray Absorption Method?

The beta ray absorption method is a measurement method that utilizes the principle that beta rays are attenuated in proportion to the mass of a substance when the substance is irradiated with beta rays, a type of radiation.

Beta rays are high-speed electrons (charged particles) ejected by the decay of unstable atomic nuclei. When beta rays pass through a substance, they collide with the atoms of the substance, causing ionization and excitation (electron orbitals rise to a higher energy level) of the atoms with beta ray absorption and emission of electromagnetic waves (X-rays) with beta ray orbital change, resulting in attenuation of the intensity of the beta rays. This attenuation of beta rays is proportional to the mass (thickness) of the substance passing through.

The mass concentration*1 of ambient particulate matter*2 can be measured using this principle. The following sections describe the measurement of ambient particulate matter using the beta ray absorption method.

*1 : Mass concentration: Mass of particulate matter per unit volume of atmosphere. The unit is μg/m3.

*2 : Ambient particulate matter: Particulate matter suspended in the atmosphere.