A great many things in the world are produced in the form of particles or powders. Some, such as food and cosmetics, are used directly in powder form, while others, such as ink in pens or paints, are used in a suspended (slurry) state. Even products like glass and batteries go through a powder phase during their manufacturing process. In these cases, the particle size distribution significantly affects the properties of the particulate materials, and serves as a key indicator of quality and performance.

Particles in suspension rarely remain isolated; they often exist in aggregated states. Therefore, evaluating the dispersion state by measuring particle size distribution is essential when handling powders. There are many forms of particulate materials, including dry powders, suspensions, emulsions, aerosols, and bubbles.

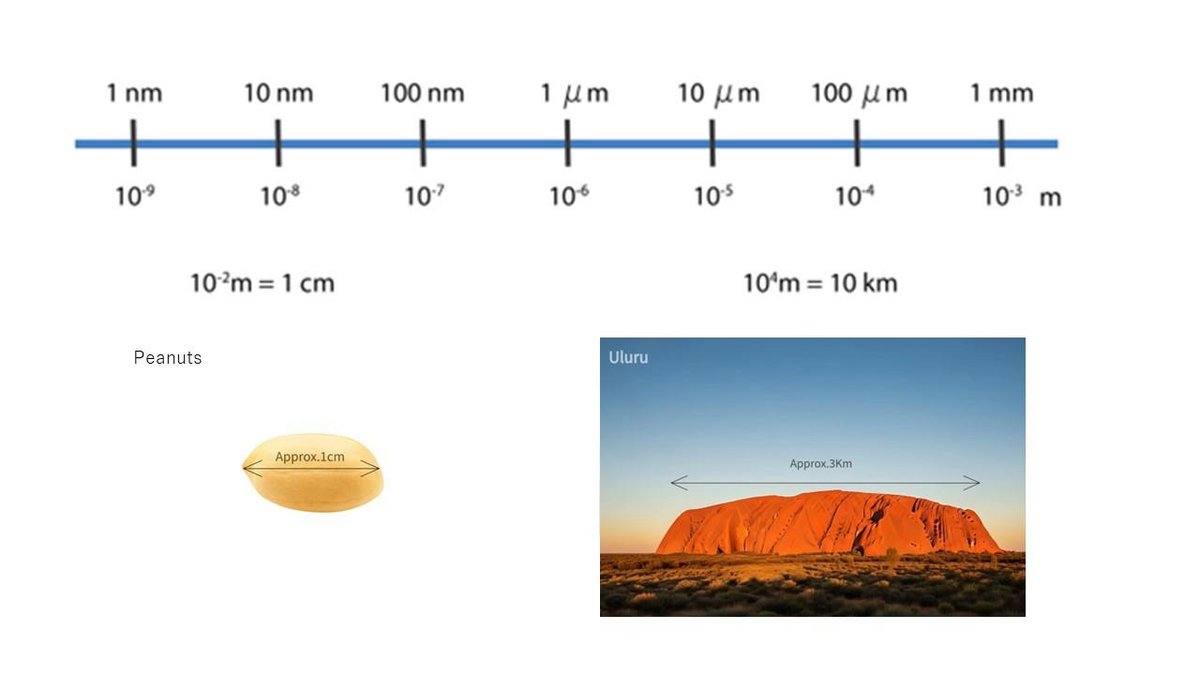

Particle sizes also vary widely—from millimeter-sized grains of sand to advanced materials as small as 1 nanometer. This six-order-of-magnitude range (a million-fold difference) can be illustrated by comparing 1 cm to 10 km—highlighting the vast range of sizes we deal with in particle analysis.

Particle size has a significant impact on powder performance. Size and shape affect flowability and compressibility. Generally, larger, spherical particles flow easily, while smaller particles with a high aspect ratio tend to flow poorly. Smaller particles also dissolve more quickly, and suspensions of smaller particles typically have higher viscosity than those of larger particles. Nanoparticles can penetrate deep into the lungs, making particle size control important for safety, as well.

Particle size distribution is also critical for controlling powder production processes. The clearest example is grinding, where the goal is to reduce particle size to a desired level. Measuring particle size allows for process monitoring and determination of the endpoint. Other processes that aim to achieve specific particle sizes include crushing, defibration, homogenization, and emulsification. Additionally, operations such as screening, filtering, and cyclone separation rely on size-based classification, while granulation and crystallization involve particle growth—each requiring particle size measurements before and after processing for proper control.

Simultaneous Multispectral Nanoparticle Tracking Analysis (NTA)

Nanoparticle Analyzer

Laser Scattering Particle Size Distribution Analyzer

У вас есть вопросы или пожелания? Используйте эту форму, чтобы связаться с нашими специалистами.