Raman spectroscopy, a rapid, non-destructive, and chemically specific analytical technique, is used extensively in the packaging industry to characterize multilayer polymer films. Through the use of Raman Spectroscopy, you can access detailed molecular fingerprints that enable researchers to identify polymer layers, assess barrier performance, and monitor the degradation of biodegradable materials, facilitating the transition toward a circular economy.

An article on this topic, titled Raman Tech Drives Packaging Sustainability, was recently published by Plastics Today. The article shows how Raman spectroscopy empowers manufacturers to analyze packaging composition without damaging the sample, ensuring the quality of recycled content and verifying the structure of complex laminates. Packaging Digest recently published. The article demonstrates the effectiveness of confocal depth profiling and chemical imaging in mapping polymer distribution and measuring layer thickness, essential steps for designing recyclable and environmentally responsible packaging solutions.

Here is the full story, which explores the specific case studies and technical insights regarding sustainable materials. Raman Tech Drives Packaging Sustainability

Raman spectroscopy aids in the design of recyclable packaging by providing a non-destructive method to identify and map the different polymer layers within a material.

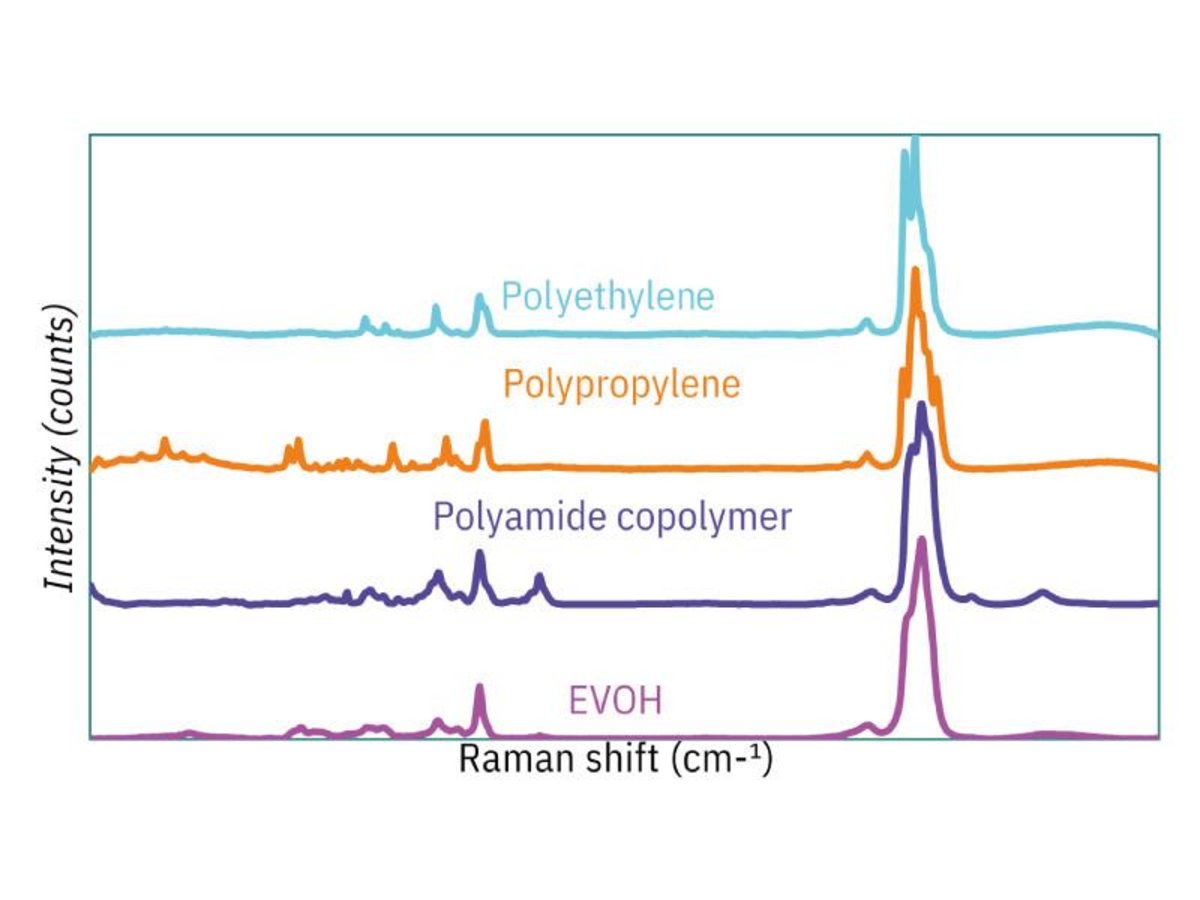

It allows manufacturers to verify the chemical composition of each layer—distinguishing between similar polymers like polyethylene (PE) and polypropylene (PP)—which is critical for assessing compatibility during the recycling process. Furthermore, it helps detect impurities or degradation in recycled content, ensuring that new packaging made from recycled materials meets quality and performance standards.

These are the two main approaches for analyzing multilayer packaging films:

Yes, Raman spectroscopy is highly effective for analyzing barrier layers such as ethylene vinyl alcohol (EVOH), which prevent moisture and oxygen from spoiling food products.

The technique can detect structural changes in these polymers after exposure to environmental factors like water or air. By identifying signs of degradation or diminished barrier performance at the molecular level, manufacturers can better predict the shelf life of the packaging and the freshness of the product inside.

For new sustainable materials like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), Raman spectroscopy is used to track degradation over time.

By monitoring changes in the chemical structure of these polymers, scientists can understand how quickly and safely they break down in the environment. This data is essential for verifying biodegradability claims and ensuring that these materials do not persist as pollutants at the end of their lifecycle.

Future developments involve integrating Raman spectroscopy with artificial intelligence (AI) and high-throughput screening.

This combination will allow for the rapid, automated testing of numerous new material formulations, accelerating the discovery of superior sustainable polymers. AI algorithms can analyze complex spectral data to predict material performance, degradation rates, and recyclability, thereby streamlining the design process for packaging that meets stringent environmental standards.

У вас есть вопросы или пожелания? Используйте эту форму, чтобы связаться с нашими специалистами.