With our water electrolysis evaluation system technology for high pressure, we do not only contribute to the development of technologies for "producing" and "storing" hydrogen at high pressure, but also provide analysis and measurement technologies related to renewable energy, as well as "turnkey management" proposals that provide total support for the design and construction of facilities, thereby helping to improve the usage rate of green hydrogen.

Water electrolysis is a mechanism that "creates" hydrogen by electrolyzing water into oxygen and hydrogen using the power of electricity.

There are four major types of water electrolysis equipment:

As the name implies, water electrolysis requires electricity, and hydrogen produced from electricity produced from renewable energy sources (wind, solar, hydro, geothermal, wave, biomass, etc.) that do not emit CO2 is called "green hydrogen" and is highly anticipated as the ultimate clean energy technology.

Table of Contents

In the production of green hydrogen by water electrolysis using renewable energy, it is important to improve the performance, durability, and low cost of the water electrolysis and steam electrolysis equipment, which is the core of the process.

Recently, the R&D of water electrolysis and fuel cell integrated cells has accelerated. In order to accelerate the R&D of electrolytic cells, it is the key to have facilities that can analyze the materials of electrodes, electrolytes, and separators, as well as comprehensively evaluate various electrolytic cells and stacks in various test environments, for example, by varying the flow rate, temperature, and humidity of PEM and SOEC cells and stacks.

Germany: Participation in the "H2Giga" project

For example, Germany, which has a higher ratio of renewable energy than Japan, is focusing on the industrialization of green hydrogen generation through water electrolysis generated from renewable energy. Therefore, investments are focused on the development of practical technologies, whether alkaline, PEM, or SOEC, that can be scaled up from the laboratory or demonstration level to the gigawatt (GW) class as quickly as possible.

HORIBA FuelCon in Germany is also participating in the "H2Giga" project initiated by the German federal government due to its advanced water electrolyzer evaluation technology.

Reference link: Federal Ministry of Education and Research (BMBF) "H2Giga" project (German)

We propose a wide range of performance and efficiency evaluation of water electrolysis cells and stacks with optimally controlling water temperature and flow rate.

HORIBA Solutions >>

Testing of PEM and alkaline Electrolyzer: Evaluator EC/ES

Testing of SOFC/SOEC Electrolyzer: Evaluator HT Series

In alkaline water electrolysis, it is necessary to control the conductivity of the water to be electrolyzed. When measuring the conductivity of alkaline water at high temperatures, ordinary electrodes are fragile, but our proprietary "ToupH" conductivity electrodes are robust enough to withstand high-temperature alkaline water.

In solid polymer (PEM) water electrolysis, the conductivity of the water to be electrolyzed is measured to determine how much of the water contains impurities that affect the electrolysis process.

We offer a wide range of pH and water quality analyzers, which are the our founding products, for both continuous measurement on the line and for laboratory use.

HORIBA Solutions >>

For controlling electrolytic water

For Process: pH, Conductivity and Water Quality Analyzers H-1 Series

For R&D: Laboratory pH and Water Quality Analyzers LAQUA Series

Photovoltaic power generation is once again in the spotlight as one of the renewable energy sources that are attracting attention toward the realization of a carbon-neutral, decarbonized society.

HORIBA proposes analytical methods for crystallinity, elemental distribution, carrier lifetime, etc. of various solar cell materials such as silicon solar cells, compound semiconductor solar cells, and organic thin film solar cells.

HORIBA Solution >>

Photovoltaics Material Analysis Solutions

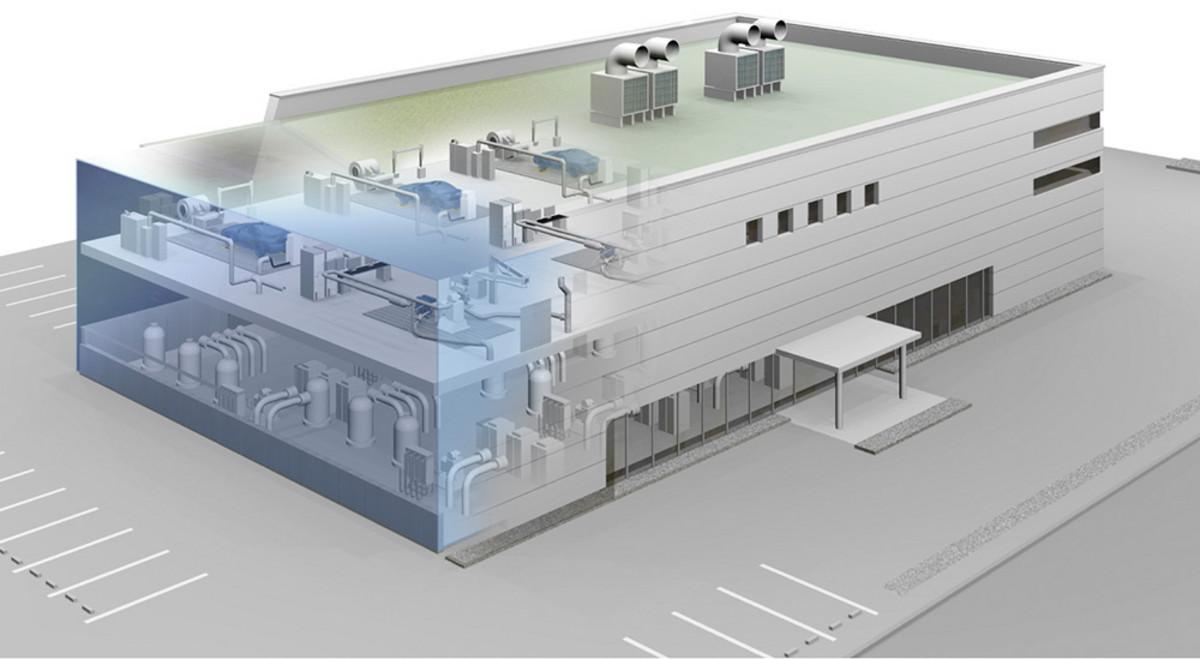

When launching a test building to handle hydrogen, more stringent safety measures are required than before.

Our turnkey solution, a total laboratory construction package, includes ordering multiple contractors, meetings to determine specifications, safety, process and quality control of construction, as well as post-introduction operation, maintenance, and work efficiency, all with an emphasis on safety and ease of use until just before the start of laboratory operations. We can handle the entire construction process on behalf of our busy customers.

HORIBA's Hydrogen Solutions

Application Laboratory Virtual Tour

Do you have any questions or requests? Use this form to contact our specialists.