Type approval for LDVs with combustion engines has never been more challenging. In Europe, emissions limits for light passenger and light commercial vehicles are stricter than ever and there is an on-going drive to reduce LDV CO2 emissions plus new/stricter test procedures came into force in 2017. Regarding this last point, type approval requires new car models be subjected to improved laboratory tests - under the EU version of the World Harmonised Light Vehicle Test Procedure (EU-WLTP) – as well on-road Real Driving Emissions (RDE) tests requiring the use of Portable Emissions Measurement Systems (PEMS).

Further regulation changes, and therefore challenges, are on the way. Are you ready?

In Europe, the EU is committed to the protection of air quality and the reduction of greenhouse gas emissions. The EURO emissions standards were introduced (EURO 1) in 1993, though rules covering air pollution from motor vehicles date back to the 1970s.

Amendments and revisions over the years have introduced progressively stricter limits and tougher tests and the current standard, EURO 6 D, allows for few discrepancies between labs results and exhaust gas emissions levels established on the road.

The pollutants measured as part of type approval under EURO 6 D are: carbon monoxide (CO), hydrocarbons (HC), oxides of nitrogen (NOx), particulate matter (PM) and the number of particles (PN). The limits differ depending on the type of combustion.

Whilst it is not known exactly is what will follow EURO 6 D - be it EURO 7 or an intermediary step (E), it is most likely that:

Help is at hand, for more information on HORIBA's solutions.

Working closely with regulatory authorities, and active on many working groups, HORIBA has a comprehensive understanding of how the legislation is changing for RDE and in the laboratory.

HORIBA have been active in the combustion engine emissions measurement and analysis industry since the 1960s and have grouped together a selection of solutions that can help you capture the data you need to make informed decisions during your R&D work, that will save you time and money through fewer prototypes, for example, and reduce your project risks.

Imagine having the world leader in emissions measurement by your side during these challenging times.

A versatile PEMS for engine monitoring under real world operating conditions. The OBS-ONE measures concentrations of emissions (CO, CO2, THC, NOx, NO2), PN, PM, air-to-fuel ratio, exhaust flow rate, GPS data, environmental conditions (atmospheric temperature, humidity and pressure) and calculates mass emissions.

These include:

A Rugged Enclosure (RE) is available.

This product is RDE+ Compatible

HORIBA’s RDE+ is an all-encompassing solution that comprises proven, robust and integrated processes and tools to support your design, development, validation and verification activities

EXFM-ONE employs an ultrasonic method for measuring exhaust gas flow rates directly from a vehicle or engine. The unit can be used for various applications such as real time mass measurement of raw exhaust gas.

These include:

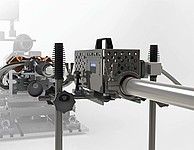

The Pitot Tube Flow Meter, PTFM-1000V2 is a standalone device for measuring the exhaust gas flow rate of a combustion engine. The system uses the tried-and-tested pitot tube principle with high-frequency transducers that ensures pulsations are not missed.

These include:

This product is RDE+ Compatible

HORIBA’s RDE+ is an all-encompassing solution that comprises proven, robust and integrated processes and tools to support your design, development, validation and verification activities

The standalone Dual Pitot Tube Flow Meter, PTFM-ONE DT is used for the measurement of engine exhaust gas flow rates for engine and chassis dyno tests. It consists of a tailpipe attached with two pitot tubes and an interface, all housed in a single chassis.

These include:

This product is RDE+ Compatible

HORIBA’s RDE+ is an all-encompassing solution that comprises proven, robust and integrated processes and tools to support your design, development, validation and verification activities

Do you have any questions or requests? Use this form to contact our specialists.