General Specification

| Scan method | Spiral scan with 1800 RPM rotation and linear motion | |||

| Laser | 20mW 355nm CW Laser * Beam size on surface : 2um diameter thru 50x objective lens | |||

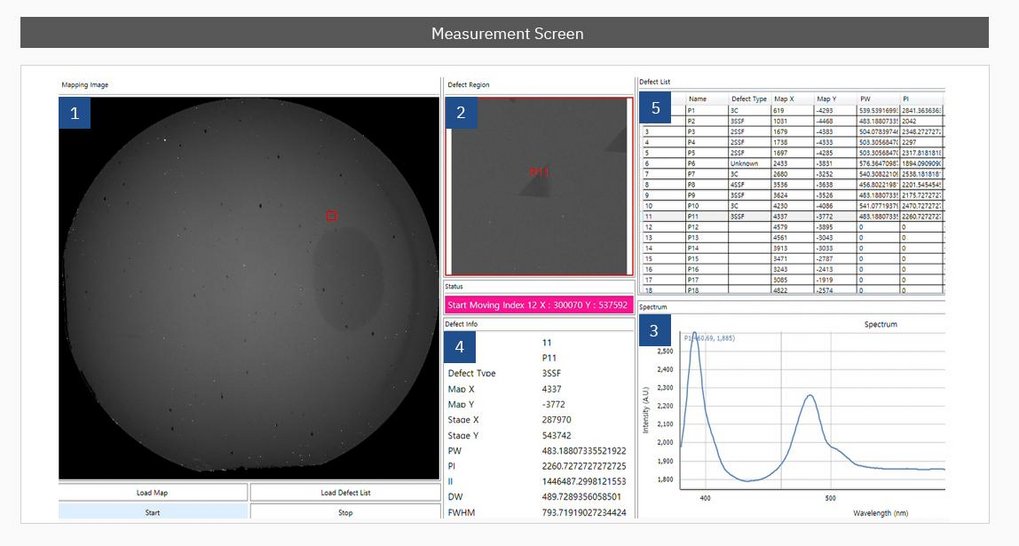

| Detector | 4 PMTs, 1 Spectrometer | |||

| Stage | XY-axis Linear stage R stage with 1800RPM (Max) | |||

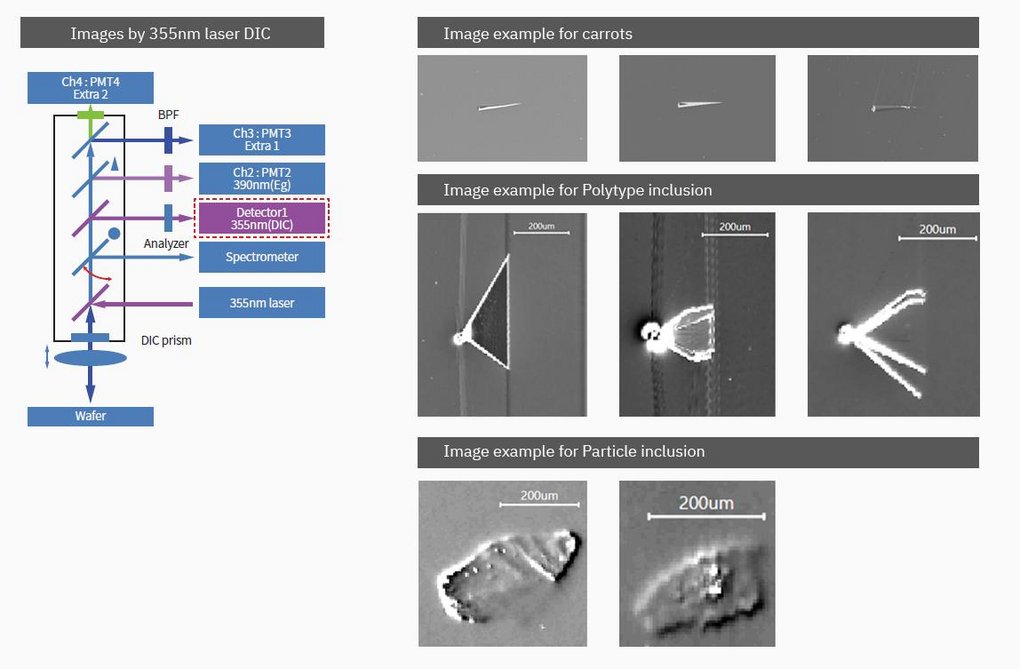

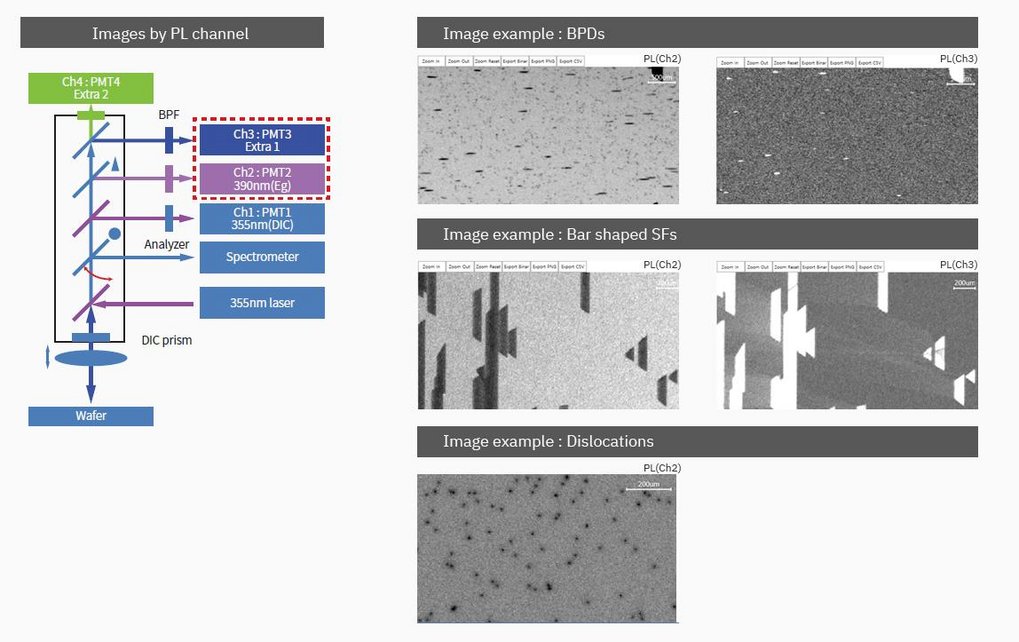

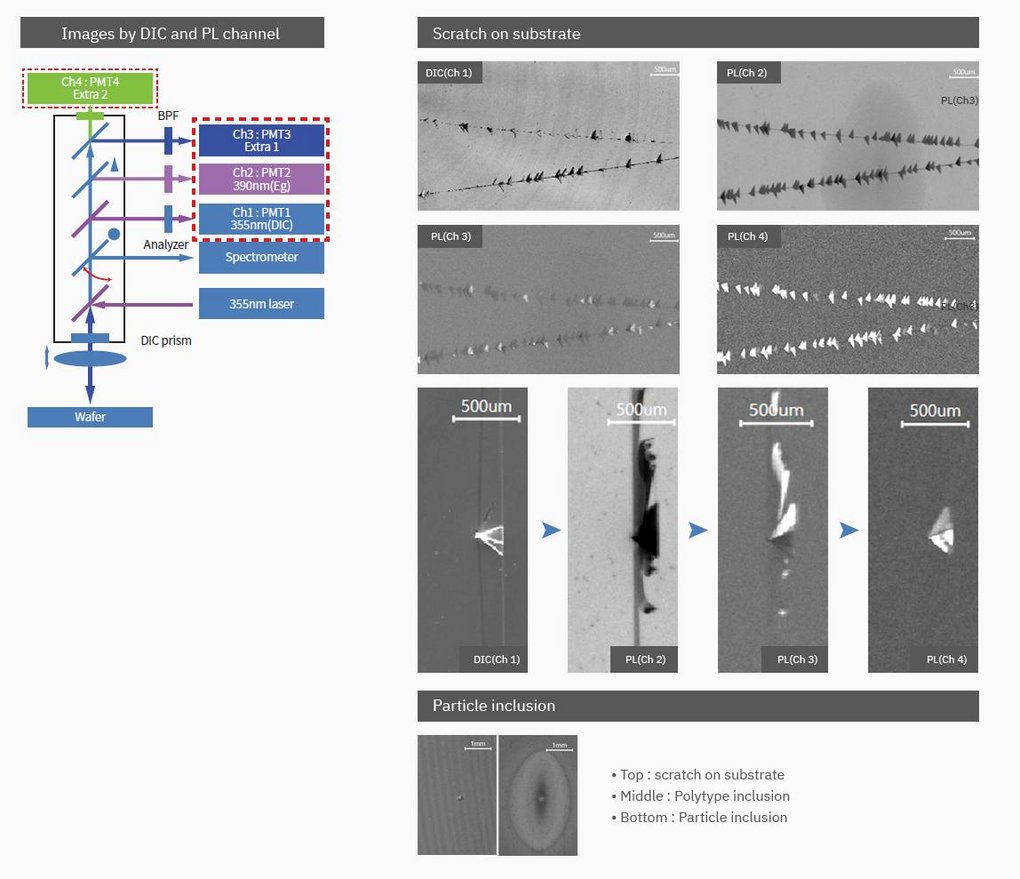

| Measurement | PMT1 | DIC 355 Laser line for surface inspection | ||

| PMT 2,3,4 | PL Port 2 (PMT 2) : PL Inspection with 390nm bandpass filter PL Port 3 (PMT 3) : 420 nm ~ 500 nm default. But customer choose bandpass filter between these range PL Port 4 (PMT 4) : 3C triangular defects with 540 nm bandpass | |||

| CCD camera | Image of designated position in analysis process | |||

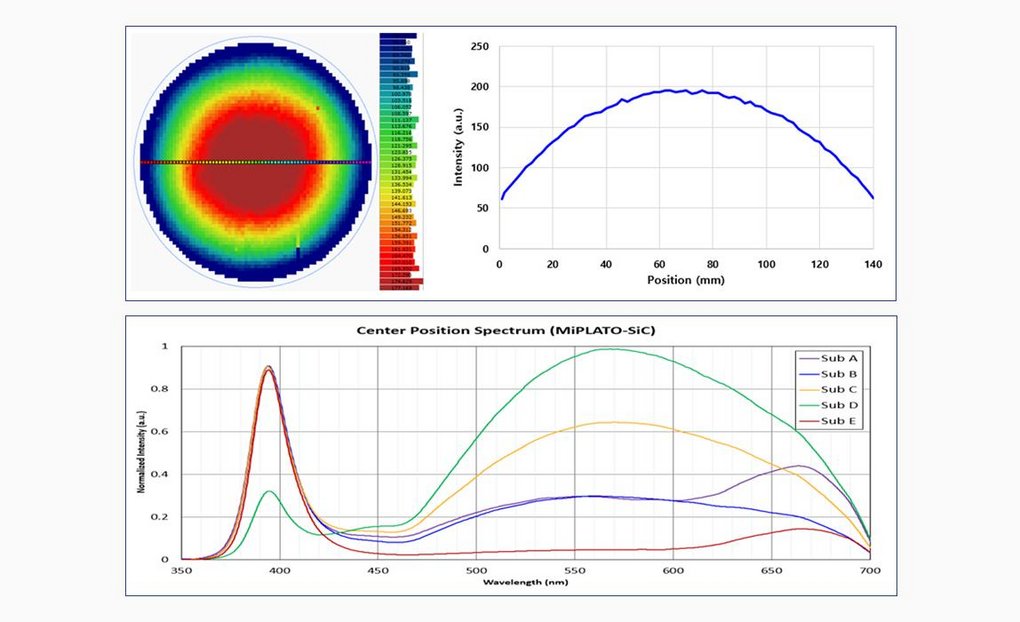

| Spectrometer | Spectrum between 380 nm ~ 700 nm Detailed defects analysis, Macroscopic wafer deep level mapping | |||

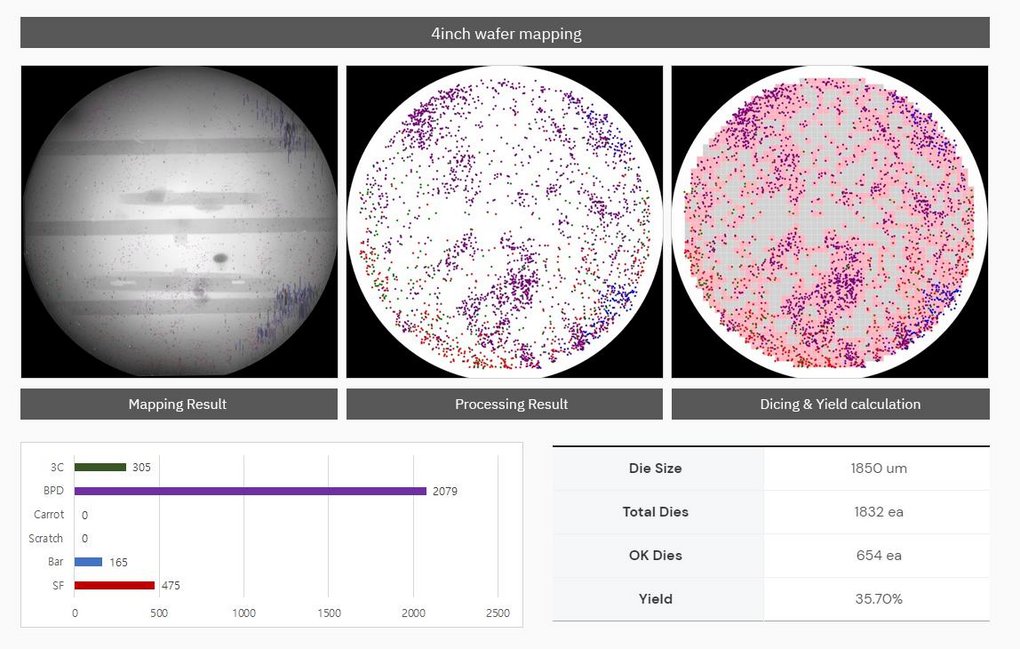

| Measurement speed | 4inch | 6inch | ||

| PMT Mapping (4 channel at same time, 5um step) | 8pcs / 1H | 6pcs / 1H | ||

| 16pcs / 2H | 12 pcs / 2H | |||

| Spectrometer mapping 3mm step | 5 min | |||

| Dimension (mm) | 2000 (w) x 1400 (d) x 2000 (h) | |||

Utility

| Operating Environment | Place | Clean Room (class ~ 10000) |

| Temperature | 15 ~ 35° C | |

| Humidity | < 85 % RH with no condensation | |

| Utility | Dimensions | 1500 mm x 2000 mm x 2300 mm, incl. HEPA filter |

| Weight | 1760 kg | |

| Input Voltage | 220V± 10% 50 / 60Hz single phase | |

| Full load current | 47A | |

| Vacuum1 | 40L / min, -80KPa Pipe size : Outer diameter 6mm | |

| Vacuum2 | 120L / min, -40KPa Pipe size : Outer diameter 6mm | |

| Air | 90L / min, 0.5MPa Pipe size : Outer diameter 6mm |